velj . 10, 2025 09:39 Back to list

4x4 welded wire mesh 6 gauge

In the field of construction and industrial applications, 4x4 welded wire mesh made of 6 gauge wire stands out as a versatile and durable product. It is critical for those in the industry to understand the multifaceted applications and benefits this particular type of wire mesh offers. This article targets the essential qualities that make 4x4 welded wire mesh a staple in building reinforcement, fencing, and beyond, highlighting experiences from industry experts and ensuring a trust-based relationship with consumers.

Moreover, 4x4 welded wire mesh is increasingly utilized in the security field because of its durability and strength. The 6 gauge thickness provides an imposing barrier that is difficult to breach without advanced tools, making it an appropriate choice for securing perimeters in high-risk areas. Field experts often recommend this type of fencing for commercial properties, where the balance between visibility and security is paramount. Additionally, the mesh can be coated with different finishes to blend with surrounding aesthetics, allowing security solutions to be both robust and discreet. A lesser-known yet significant application is in the realm of art and sculpture. Artists across the globe are embracing 4x4 welded wire mesh for its blend of rigidity and ease of manipulation. This mesh allows for creative structures that maintain their form and integrity over time. Trust in the material's sturdiness provides artists with creative freedom, knowing their work will withstand the elements and maintain its intended form. In conclusion, the 4x4 welded wire mesh 6 gauge product is an invaluable material in many domains, from construction and agriculture to art. Its diverse applications highlight its adaptability and strength, providing a reliable solution for various needs. Consumers and professionals can trust this mesh to deliver long-lasting performance due to its expert design and construction. When considering materials that offer both resilience and flexibility, this particular wire mesh proves itself time and again as an authoritative choice. As echoed by professionals across industries, investing in quality materials like this pays dividends in safety, reliability, and overall satisfaction.

Moreover, 4x4 welded wire mesh is increasingly utilized in the security field because of its durability and strength. The 6 gauge thickness provides an imposing barrier that is difficult to breach without advanced tools, making it an appropriate choice for securing perimeters in high-risk areas. Field experts often recommend this type of fencing for commercial properties, where the balance between visibility and security is paramount. Additionally, the mesh can be coated with different finishes to blend with surrounding aesthetics, allowing security solutions to be both robust and discreet. A lesser-known yet significant application is in the realm of art and sculpture. Artists across the globe are embracing 4x4 welded wire mesh for its blend of rigidity and ease of manipulation. This mesh allows for creative structures that maintain their form and integrity over time. Trust in the material's sturdiness provides artists with creative freedom, knowing their work will withstand the elements and maintain its intended form. In conclusion, the 4x4 welded wire mesh 6 gauge product is an invaluable material in many domains, from construction and agriculture to art. Its diverse applications highlight its adaptability and strength, providing a reliable solution for various needs. Consumers and professionals can trust this mesh to deliver long-lasting performance due to its expert design and construction. When considering materials that offer both resilience and flexibility, this particular wire mesh proves itself time and again as an authoritative choice. As echoed by professionals across industries, investing in quality materials like this pays dividends in safety, reliability, and overall satisfaction.

Pervious:

Next:

Latest news

-

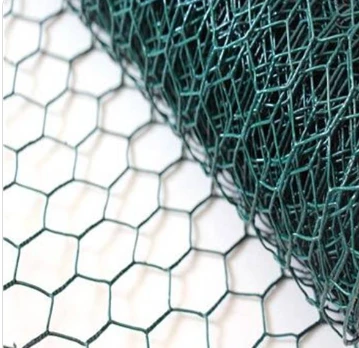

The Versatility and Durability of PVC Coated Wire Mesh

NewsJun.10,2025

-

The Strength and Durability of Galvanized Welded Wire Mesh

NewsJun.10,2025

-

The Ideal Home for Your Pet with a Wire Dog Crate

NewsJun.10,2025

-

Secure Your Property with High-Quality Razor Wire

NewsJun.10,2025

-

PVC Coated Wire-- A Durable Solution for Every Application

NewsJun.10,2025

-

Enhance Your Home’s Entrance with Beautiful Garden Gates

NewsJun.10,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US