velj . 07, 2025 05:03 Back to list

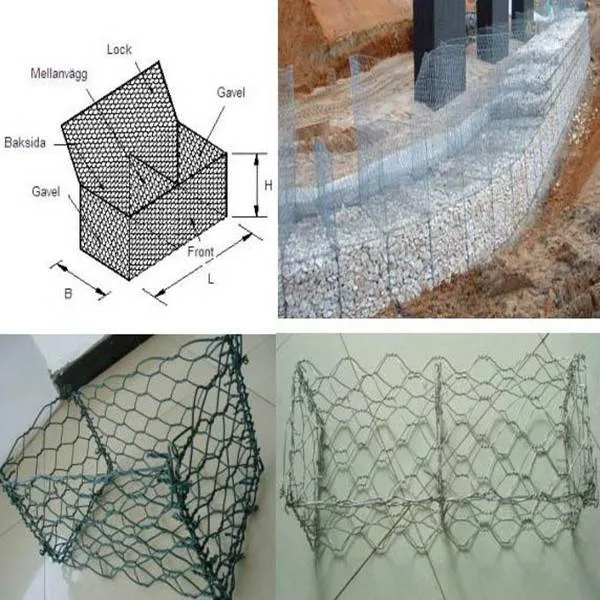

Welded Mesh Gabion

The widespread application of the 2x3 welded wire has transformed various industries with its impressive blend of durability, safety, and versatility. For professionals looking to incorporate this material into their projects, understanding its nuances can unlock new dimensions in efficiency and reliability.

When scrutinizing alternatives such as traditional fencing or expanded metal, 2x3 welded wire offers unmatched advantages. Notably, the welds provide inherent strength at junction points, a feature often absent in other materials. This aspect is crucial in high-stress environments where durability cannot be compromised. Its aesthetic appearance also pairs well with functionality, providing a visually appealing solution without sacrificing performance. Experience-Backed Application Examples Our experience with varied client demands further substantiates the significance of 2x3 welded wire. In one notable project, a sustainable farm integrated the wire for perimeter fencing and animal enclosures, praising its ability to withstand harsh environmental conditions while maintaining safety. Another case involves a construction firm that used the wire within concrete slabs—reporting enhanced structural stability and easier installation compared to previous alternatives. These real-world applications showcase the material's reliability and versatility across demands. Cost Efficiency and Longevity From a financial standpoint, the initial investment in 2x3 welded wire is mitigated by its long operational life and low maintenance requirements. The one-time setup costs are counterbalanced by reduced expenditure on repairs and replacements, making it a cost-effective solution in the long run. Additionally, its resilience translates to fewer disruptions, thus ensuring productivity remains unaffected. Consultation and Professional Advice To achieve optimal results, consulting industry experts who have extensive experience with 2x3 welded wire is advisable. Professionals can offer insights into brand recommendations, installation techniques, and maintenance tips, tailoring their advice to specific industry needs. These consultations not only boost efficiency but also impart invaluable knowledge, enhancing the overall trustworthiness of the project outcomes. Conclusion The 2x3 welded wire continues to be an industry favorite due to its robust construction, versatility, and economic advantages. Its balance of strength and adaptability makes a significant impact when utilized correctly—ensuring safety and longevity, and reinforcing its standing as a credible and authoritative choice. For industries aiming to enhance their infrastructure with tested and trusted materials, 2x3 welded wire remains an unrivaled option. Embrace this reliable material by exploring its potential applications, backed by expertise and real-world successes.

When scrutinizing alternatives such as traditional fencing or expanded metal, 2x3 welded wire offers unmatched advantages. Notably, the welds provide inherent strength at junction points, a feature often absent in other materials. This aspect is crucial in high-stress environments where durability cannot be compromised. Its aesthetic appearance also pairs well with functionality, providing a visually appealing solution without sacrificing performance. Experience-Backed Application Examples Our experience with varied client demands further substantiates the significance of 2x3 welded wire. In one notable project, a sustainable farm integrated the wire for perimeter fencing and animal enclosures, praising its ability to withstand harsh environmental conditions while maintaining safety. Another case involves a construction firm that used the wire within concrete slabs—reporting enhanced structural stability and easier installation compared to previous alternatives. These real-world applications showcase the material's reliability and versatility across demands. Cost Efficiency and Longevity From a financial standpoint, the initial investment in 2x3 welded wire is mitigated by its long operational life and low maintenance requirements. The one-time setup costs are counterbalanced by reduced expenditure on repairs and replacements, making it a cost-effective solution in the long run. Additionally, its resilience translates to fewer disruptions, thus ensuring productivity remains unaffected. Consultation and Professional Advice To achieve optimal results, consulting industry experts who have extensive experience with 2x3 welded wire is advisable. Professionals can offer insights into brand recommendations, installation techniques, and maintenance tips, tailoring their advice to specific industry needs. These consultations not only boost efficiency but also impart invaluable knowledge, enhancing the overall trustworthiness of the project outcomes. Conclusion The 2x3 welded wire continues to be an industry favorite due to its robust construction, versatility, and economic advantages. Its balance of strength and adaptability makes a significant impact when utilized correctly—ensuring safety and longevity, and reinforcing its standing as a credible and authoritative choice. For industries aiming to enhance their infrastructure with tested and trusted materials, 2x3 welded wire remains an unrivaled option. Embrace this reliable material by exploring its potential applications, backed by expertise and real-world successes.

Pervious:

Next:

Latest news

-

The Versatility and Durability of PVC Coated Wire Mesh

NewsJun.10,2025

-

The Strength and Durability of Galvanized Welded Wire Mesh

NewsJun.10,2025

-

The Ideal Home for Your Pet with a Wire Dog Crate

NewsJun.10,2025

-

Secure Your Property with High-Quality Razor Wire

NewsJun.10,2025

-

PVC Coated Wire-- A Durable Solution for Every Application

NewsJun.10,2025

-

Enhance Your Home’s Entrance with Beautiful Garden Gates

NewsJun.10,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US