sij . 30, 2025 05:00 Back to list

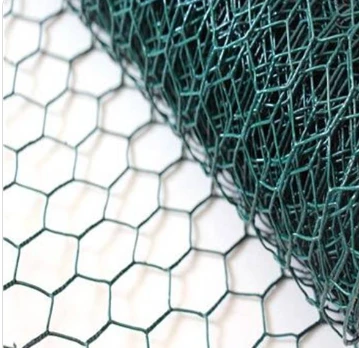

Welded Mesh Gabion

The versatility and durability of welded wire mesh have made it an indispensable component in many industries, and particular specifications such as the 1 2 x 1 2 welded wire mesh have gathered significant attention. As a trusted product in various applications, this wire mesh size offers several advantages that make it stand out.

Security is another critical area where welded wire mesh proves indispensable. Facilities often require robust perimeter fencing, and the dense mesh of the 1 2 x 1 2 dimensions deters intruders efficiently due to its tough fabrication. It is also used in infills for balustrades and stairwells, offering protection without compromising visibility or aesthetic appeal. In addition to these practical applications, welded wire mesh in these dimensions is also utilized in artistic and architectural designs. Designers and artists are increasingly recognizing its aesthetic potential, using the mesh to create modern, industrial-inspired art installations and functional decor elements. The mesh’s clean lines and metallic sheen provide a contemporary look that can enhance public spaces and private residences alike. Investing in high-quality 1 2 x 1 2 welded wire mesh means prioritizing reliability and longevity. For businesses and individuals alike, choosing trusted manufacturers ensures the material is produced to optimal standards, which is crucial in bearing loads and resisting deformations. Verifying certifications and quality marks are essential steps to confirm the material meets industry standards. Customization is another aspect where this mesh excels. Manufacturers can adjust the wire gauge, material composition, and finishes to tailor the product for specific needs—whether it's for increased security levels or aesthetic requirements. As such, consulting with experts can help leverage the maximum benefits from the mesh, aligning it perfectly with the intended application. Overall, the use of 1 2 x 1 2 welded wire mesh signals a commitment to quality and excellence across multiple fields. Whether for enhanced security, structural reinforcement, or aesthetic applications, its superior construction offers unmatched benefits that are crucial for modern industry demands. With ongoing innovation and expertise, this mesh continues to stand as a testament to the efficacy of welded mesh solutions.

Security is another critical area where welded wire mesh proves indispensable. Facilities often require robust perimeter fencing, and the dense mesh of the 1 2 x 1 2 dimensions deters intruders efficiently due to its tough fabrication. It is also used in infills for balustrades and stairwells, offering protection without compromising visibility or aesthetic appeal. In addition to these practical applications, welded wire mesh in these dimensions is also utilized in artistic and architectural designs. Designers and artists are increasingly recognizing its aesthetic potential, using the mesh to create modern, industrial-inspired art installations and functional decor elements. The mesh’s clean lines and metallic sheen provide a contemporary look that can enhance public spaces and private residences alike. Investing in high-quality 1 2 x 1 2 welded wire mesh means prioritizing reliability and longevity. For businesses and individuals alike, choosing trusted manufacturers ensures the material is produced to optimal standards, which is crucial in bearing loads and resisting deformations. Verifying certifications and quality marks are essential steps to confirm the material meets industry standards. Customization is another aspect where this mesh excels. Manufacturers can adjust the wire gauge, material composition, and finishes to tailor the product for specific needs—whether it's for increased security levels or aesthetic requirements. As such, consulting with experts can help leverage the maximum benefits from the mesh, aligning it perfectly with the intended application. Overall, the use of 1 2 x 1 2 welded wire mesh signals a commitment to quality and excellence across multiple fields. Whether for enhanced security, structural reinforcement, or aesthetic applications, its superior construction offers unmatched benefits that are crucial for modern industry demands. With ongoing innovation and expertise, this mesh continues to stand as a testament to the efficacy of welded mesh solutions.

Pervious:

Next:

Latest news

-

The Versatility and Durability of PVC Coated Wire Mesh

NewsJun.10,2025

-

The Strength and Durability of Galvanized Welded Wire Mesh

NewsJun.10,2025

-

The Ideal Home for Your Pet with a Wire Dog Crate

NewsJun.10,2025

-

Secure Your Property with High-Quality Razor Wire

NewsJun.10,2025

-

PVC Coated Wire-- A Durable Solution for Every Application

NewsJun.10,2025

-

Enhance Your Home’s Entrance with Beautiful Garden Gates

NewsJun.10,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US