loka . 30, 2024 12:28 Back to list

iron mesh cost

Cost Analysis of Iron Mesh Factors and Considerations

Iron mesh is an essential material in various industries, from construction and engineering to agriculture and security. Understanding the cost of iron mesh is crucial for businesses and individuals who plan to incorporate it into their projects. This article delves into the factors affecting the cost of iron mesh and presents a comprehensive overview of what to consider when budgeting for this material.

Factors Influencing Iron Mesh Cost

1. Raw Material Prices The primary component of iron mesh is iron itself, which is subject to fluctuations in global market prices. Factors such as mining costs, transportation, and tariffs can influence the price of raw iron, thereby affecting the final cost of iron mesh. Monitoring market trends and seeking suppliers with stable pricing can help mitigate these costs.

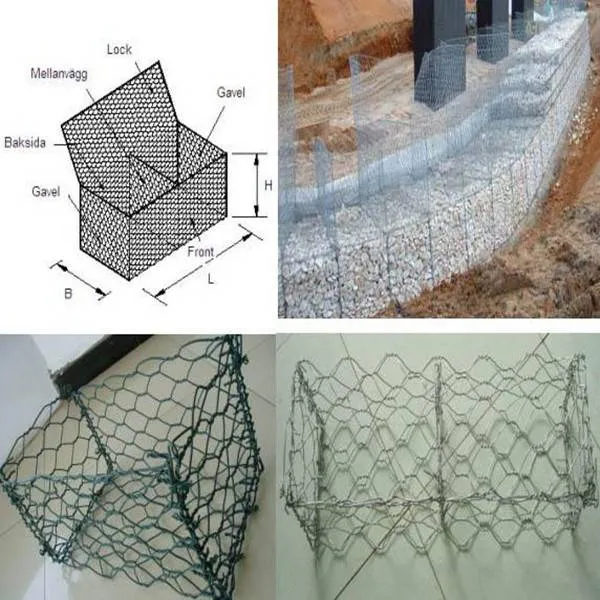

2. Type of Iron Mesh There are various types of iron mesh available, including welded, woven, and expanded mesh. Each type comes with a different manufacturing process, which impacts the cost. For instance, welded mesh tends to be more expensive due to the additional labor and technology involved in its production compared to woven mesh.

3. Mesh Size and Thickness The size and thickness of the mesh directly influence its cost. Thicker and larger mesh panels typically require more material, leading to higher prices. Conversely, smaller, thinner meshes are generally more affordable. It is essential to select the right size and thickness based on the specific application to balance cost and functionality.

iron mesh cost

4. Surface Treatment Iron mesh can undergo various surface treatments, such as galvanization, painting, or coating, to enhance durability and resistance to rust and corrosion. While these treatments increase the initial cost, they can lead to lower maintenance costs in the long run, making them a worthwhile investment.

5. Order Volume The quantity of iron mesh purchased can also affect pricing. Bulk orders often qualify for discounts, which can significantly lower the cost per unit. Planning ahead and purchasing in bulk when possible can help save money, especially for large-scale projects.

6. Supplier Location and Shipping Costs The geographic location of the supplier can impact the overall cost due to shipping expenses. Local suppliers may offer better prices due to lower transportation costs, whereas importing iron mesh from overseas could result in additional fees, including customs duties and longer lead times.

Budgeting for Iron Mesh

When budgeting for iron mesh, it’s essential to account for not just the material cost but also the associated expenses. These may include shipping, labor for installation, and potential maintenance or treatment costs. Additionally, it’s advisable to compare quotes from multiple suppliers to ensure competitive pricing and to investigate the reputation and reliability of these suppliers.

In conclusion, the cost of iron mesh is a multifaceted issue influenced by a variety of factors, from raw material prices to order volume. By understanding these elements, businesses and individuals can make informed decisions that ensure they get the best value for their investment in iron mesh. Proper planning and strategic purchasing can lead to substantial savings and enhanced project outcomes, making the careful consideration of iron mesh costs a vital part of any project’s success.

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NewsAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NewsAug.23,2025

-

Garden Edging Fence for Functional and Decorative Landscaping

NewsAug.23,2025

-

3D Wire Mesh Fence for Versatile Security and Decoration

NewsAug.23,2025

Products categories