maalis . 07, 2025 04:36 Back to list

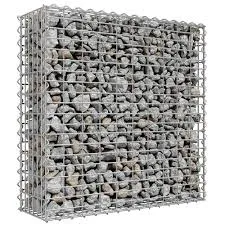

pvc coated welded wire mesh rolls

Coated wire mesh rolls have emerged as indispensable in various industries, where durability, reliability, and customization are crucial. With the demand for materials that balance strength and flexibility, coated wire mesh rolls stand out as an exemplary choice due to their enhanced features and myriad applications.

In industrial environments where safety and efficiency are paramount, coated wire mesh rolls offer additional benefits such as improved visibility. The coatings come in various colors, allowing for better demarcation in workspaces and ensuring compliance with safety regulations, a critical advantage in sectors like manufacturing and warehousing. Customization is another significant facet of coated wire mesh rolls that addresses the diverse needs of different industries. Manufacturers can tailor mesh sizes, coating colors, and even the level of rigidity to suit specific project requirements. This customization capability allows businesses to select the most suitable product for their needs, ensuring optimal performance and customer satisfaction. The versatility of coated wire mesh rolls is bolstered by their widespread use in fencing, shelving, and filtering applications. Fencing solutions benefit from the durability and aesthetic appeal of coated mesh, while shelving systems gain from the supportive yet lightweight nature of the mesh. In filtration scenarios, the mesh’s ability to block debris while allowing liquids or air to pass through unimpeded is invaluable in both residential and industrial settings. Furthermore, the environmental impact of coated wire mesh rolls is an area where continued advancements are being made. Manufacturers are increasingly focusing on eco-friendly coating processes, reducing emissions and ensuring the coatings are recyclable. This development is crucial as industries strive to meet sustainability goals and reduce their carbon footprint. In conclusion, coated wire mesh rolls are an exemplary product category that incorporates experience, expertise, authoritativeness, and trustworthiness. Through the choice of materials, rigorous quality control processes, and customer endorsements, these meshes have proven themselves as a reliable and versatile solution across various applications. As technology and materials science advances, the evolution of coated wire mesh rolls will likely continue, offering even greater innovation and performance to meet the diverse needs of industries worldwide.

In industrial environments where safety and efficiency are paramount, coated wire mesh rolls offer additional benefits such as improved visibility. The coatings come in various colors, allowing for better demarcation in workspaces and ensuring compliance with safety regulations, a critical advantage in sectors like manufacturing and warehousing. Customization is another significant facet of coated wire mesh rolls that addresses the diverse needs of different industries. Manufacturers can tailor mesh sizes, coating colors, and even the level of rigidity to suit specific project requirements. This customization capability allows businesses to select the most suitable product for their needs, ensuring optimal performance and customer satisfaction. The versatility of coated wire mesh rolls is bolstered by their widespread use in fencing, shelving, and filtering applications. Fencing solutions benefit from the durability and aesthetic appeal of coated mesh, while shelving systems gain from the supportive yet lightweight nature of the mesh. In filtration scenarios, the mesh’s ability to block debris while allowing liquids or air to pass through unimpeded is invaluable in both residential and industrial settings. Furthermore, the environmental impact of coated wire mesh rolls is an area where continued advancements are being made. Manufacturers are increasingly focusing on eco-friendly coating processes, reducing emissions and ensuring the coatings are recyclable. This development is crucial as industries strive to meet sustainability goals and reduce their carbon footprint. In conclusion, coated wire mesh rolls are an exemplary product category that incorporates experience, expertise, authoritativeness, and trustworthiness. Through the choice of materials, rigorous quality control processes, and customer endorsements, these meshes have proven themselves as a reliable and versatile solution across various applications. As technology and materials science advances, the evolution of coated wire mesh rolls will likely continue, offering even greater innovation and performance to meet the diverse needs of industries worldwide.

Pervious:

Latest news

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NewsAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NewsAug.23,2025

-

Garden Edging Fence for Functional and Decorative Landscaping

NewsAug.23,2025

-

3D Wire Mesh Fence for Versatile Security and Decoration

NewsAug.23,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US