elo . 26, 2025 05:20 Back to list

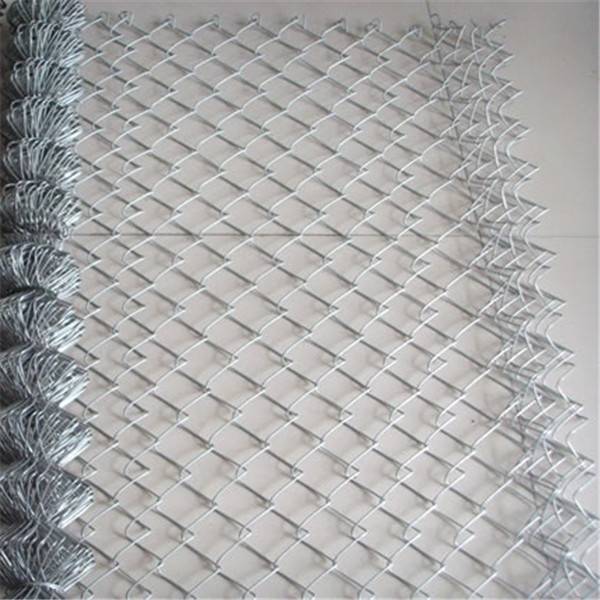

Buy Chain Link Fence: Affordable, Durable Security Fencing

Industry Trends in Chain Link Fencing Solutions

The global demand for perimeter security and demarcation solutions continues to drive innovation within the chain link fence market. Current industry trends indicate a significant shift towards enhanced durability, specialized coatings, and integration with advanced security systems. Enterprises looking to buy chain link fence are increasingly prioritizing solutions that offer not just physical barriers but also long-term cost-efficiency and minimal maintenance requirements. Key growth drivers include robust infrastructure development, stringent security regulations across industrial sectors, and a rising focus on sustainable, long-lasting materials.

Technological advancements are leading to more sophisticated manufacturing processes, resulting in stronger wires, improved galvanization techniques, and the proliferation of vinyl-coated options that resist corrosion and UV degradation more effectively. Furthermore, the market sees a growing demand for customized heights and gauges, from light-duty residential applications to heavy-duty industrial security, including specific requirements for 7 chain link fence, 10 chain link fence, and even specialized 36 chain link fence systems for high-security applications or wildlife management.

This evolution underscores a broader industry move towards integrated solutions where the fence is a component of a larger security ecosystem, often paired with access control, surveillance, and intelligent monitoring. Such comprehensive approaches offer superior protection against unauthorized access and environmental challenges, making the choice of the right chain link fence a critical operational decision for B2B stakeholders.

Manufacturing Process Flow for High-Quality Chain Link Fence

The production of a robust buy chain link fence involves a meticulous multi-stage process designed to ensure durability, structural integrity, and long-term performance. Understanding this process is crucial for B2B buyers seeking high-quality, reliable fencing solutions.

Materials Selection and Preparation:

The foundation of any superior chain link fence begins with the selection of premium wire rod. Typically, low-carbon steel wire is chosen for its ductility and strength. For enhanced corrosion resistance, galvanized steel wire is paramount, often employing hot-dip galvanization for a thick, uniform zinc coating. Vinyl-coated options utilize galvanized wire further coated with PVC, available in various colors for aesthetic and additional protective benefits. Wire gauges commonly range from 11-gauge for light-duty residential applications to 9-gauge or even 6-gauge for heavy-duty industrial security, impacting the overall `chain link fence wire` strength.

Weaving Process:

- Wire Feeding: Large spools of wire (galvanized or vinyl-coated) are fed into specialized weaving machines.

- Interlocking: The machines are calibrated to interlock the wires, forming the characteristic diamond pattern. This is a continuous process, where a single wire is spiral-wound through the previous spiral, creating a strong, flexible mesh.

- Knuckling or Twisting: At each end of the mesh, the wire ends are either "knuckled" (bent over to form a smooth, rounded edge) or "twisted" (twisted together to form a barb-like projection). Knuckling is standard for safety and aesthetics, while twisting offers additional security.

- Rolling: The finished mesh is then rolled onto large spools or cut into specific lengths for easier transport and installation.

Post-Processing and Quality Control:

After weaving, the `chain link fence` undergoes rigorous quality checks. Key testing standards often include:

- ASTM A392: Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric.

- ASTM F668: Standard Specification for Polyvinyl Chloride (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric.

- ISO 9227: Corrosion tests in artificial atmospheres (e.g., salt spray tests) to evaluate coating durability.

- Tensile Strength Testing: To ensure the wire meets specified breaking strength requirements.

- Coating Thickness Measurement: Verification of galvanization or PVC coating thickness for optimal corrosion resistance.

The service life of a properly manufactured and installed `chain link fence` can range from 15 years for standard galvanized options to over 25 years for heavy-duty galvanized or PVC-coated systems, even exceeding 30 years in favorable conditions.

Advantages in Typical Application Scenarios:

- Petrochemical Industry: Superior corrosion resistance of galvanized and PVC-coated fences protects against harsh chemical environments, ensuring perimeter integrity and safety.

- Metallurgy: Robust wire gauges and high tensile strength prevent breaches in demanding industrial settings, providing secure containment for valuable assets and hazardous areas.

- Water Supply & Drainage: The open weave design allows for minimal wind resistance, crucial in exposed areas, while corrosion-resistant coatings guarantee longevity in moist or aggressive soil conditions. The cost-effectiveness compared to solid barriers also means significant project savings in extensive infrastructure projects, influencing the overall `chain link fence cost`.

- Energy Sector: Fences contribute to energy saving by being a more lightweight and less resource-intensive option compared to masonry walls, yet providing effective security. Their transparency allows for passive surveillance without obstructing line of sight, crucial for monitoring large energy installations.

Technical Specifications and Performance Parameters

Choosing the right `chain link fence` requires a thorough understanding of its technical specifications. These parameters directly influence the fence's performance, durability, and suitability for specific applications. Our range ensures compliance with international standards and diverse operational demands for customers seeking to `buy chain link fence`.

Key Product Specifications:

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Wire Gauge (SWG) | Diameter of the steel wire, inversely proportional to strength. Lower gauge means thicker, stronger wire. | 12.5 ga - 6 ga (2.5mm - 4.88mm) |

| Mesh Size | The diagonal measurement of the diamond opening in the fabric. Smaller mesh provides more security. | 2" x 2" (50mm x 50mm) to 2.375" x 2.375" (60mm x 60mm) |

| Material | Base metal used for the wire. | Low Carbon Steel, Stainless Steel (304, 316) |

| Coating Type | Protective layer for corrosion resistance and aesthetics. | Hot-Dip Galvanized (HDG), Electro-Galvanized, PVC Coated, Aluminized |

| Zinc Coating Weight | Minimum amount of zinc per unit area for galvanized wire, per ASTM A392. | 1.2 oz/ft² (366 g/m²) minimum |

| Height | Overall vertical dimension of the fence fabric. | 4 ft (1.2m) to 12 ft (3.6m), custom heights available (e.g., 36 chain link fence, 7 chain link fence) |

| Tensile Strength | Resistance of the wire to breaking under tension. | Minimum 75,000 PSI (517 MPa) for core wire |

Understanding these specifications allows for informed decisions, ensuring that the chosen chain link fence meets the precise requirements for security, longevity, and regulatory compliance. Factors like `chain link fence wire` thickness and coating type significantly impact performance in diverse environmental conditions.

Application Scenarios and Practical Deployments

The versatility of chain link fencing makes it an indispensable asset across a multitude of B2B applications. From industrial security to public infrastructure, its adaptability in height, gauge, and finish ensures optimal performance.

Industrial Perimeters:

For factories, warehouses, and logistics hubs, `chain link fence` serves as a primary security barrier. High-gauge wire (e.g., 9-gauge or 6-gauge) combined with commercial-grade `chain link fence poles` and barbed wire or razor wire toppings provide robust intrusion deterrence. Its transparency also aids surveillance systems, reducing blind spots.

Sports and Recreational Facilities:

Baseball fields, tennis courts, and golf courses frequently utilize chain link for boundary demarcation and ball containment. Heights like 10 chain link fence are common to prevent objects from leaving the playing area, ensuring public safety and operational efficiency.

Correctional and High-Security Areas:

In sensitive environments, specialized high-security chain link with smaller mesh sizes (e.g., micro-mesh) and formidable `chain link fence poles` is deployed to prevent climbing and cutting. These installations often feature enhanced coatings for maximum service life under constant exposure.

Infrastructure Projects:

Highways, railway lines, and utility substations leverage chain link for safety and security. It effectively deters trespassers and vandalism while requiring minimal maintenance over vast linear distances. Specific heights like 7 chain link fence are frequently specified to meet safety codes without excessive material costs.

Animal Enclosures and Agricultural Boundaries:

For zoos, farms, and wildlife management areas, chain link provides secure and humane enclosures. Larger mesh sizes can be used for larger animals, while smaller mesh prevents smaller animals from escaping. Specialized applications may even require 36 chain link fence systems for wildlife corridors or large agricultural boundaries.

Technical Advantages of Our Chain Link Fence Systems

When organizations choose to buy chain link fence from our portfolio, they invest in a product designed for superior technical performance, longevity, and cost-effectiveness. Our advanced manufacturing processes and material selection translate into tangible benefits for industrial and commercial applications.

Unmatched Durability and Corrosion Resistance:

Our galvanized `chain link fence wire` adheres to ASTM A392 Class 2 standards, ensuring a minimum zinc coating of 1.2 oz/ft². This robust coating provides exceptional protection against rust and environmental degradation, significantly extending service life in harsh climates. For even greater resistance, our PVC-coated options provide an additional barrier against chemicals, salt spray, and UV radiation, tested per ISO 9227 standards, making them ideal for coastal or industrial corrosive environments.

High Tensile Strength and Impact Resistance:

Utilizing high-grade steel wire with a tensile strength exceeding 75,000 PSI, our fences offer superior resistance to cutting, bending, and impact. This intrinsic strength, coupled with various wire gauges (from 11-gauge to heavy-duty 6-gauge), ensures a formidable physical barrier against unauthorized entry or accidental damage. The interlocked diamond mesh design distributes force efficiently, preventing localized failure.

Cost-Effectiveness and Low Maintenance:

While initial `chain link fence cost` is competitive, the long-term value is amplified by minimal maintenance requirements. The inherent durability and corrosion resistance reduce the need for frequent repairs or replacements. Unlike opaque fencing, chain link allows for natural light and air flow, reducing microclimates that can foster degradation of other assets. Its open design also facilitates easier inspection and security monitoring, lowering operational overhead.

Versatility and Adaptability:

Our systems offer unparalleled flexibility in application. Available in various heights (e.g., standard 6-foot, 7 chain link fence, 10 chain link fence, up to 12-foot and custom `36 chain link fence` for specialized needs) and mesh sizes, they can be configured with different top and bottom finishes (knuckled or barbed) to meet specific security levels. The ease of integrating barbed wire, razor wire, access gates, and security sensors further enhances their protective capabilities.

Vendor Comparison: Why Choose Our Solutions

When making a strategic decision to buy chain link fence, selecting the right vendor is as critical as choosing the right product. Our commitment to quality, compliance, and comprehensive support distinguishes us in a competitive market.

Comparative Analysis of Chain Link Fence Providers:

| Feature | Our Offering | Typical Competitor |

|---|---|---|

| Certifications & Standards | ISO 9001:2015 certified, ASTM A392 & F668 compliant, CE Mark. | Often limited to basic ASTM, less consistent ISO compliance. |

| Material Quality (Wire) | High-tensile, virgin steel core. Hot-dip galvanized (1.2 oz/ft² min) or premium PVC coated (8-10 mil thickness). | Recycled steel, lower zinc coating (0.8 oz/ft²), thinner PVC (5-6 mil). Potential for `cheap chain link fence` but lower durability. |

| Product Range | Extensive: 6-12 gauge wire, 2"-0.5" mesh, heights from 4ft to 12ft (including 7 chain link fence, 10 chain link fence, 36 chain link fence), full range of `chain link fence poles` and fittings. | Standard sizes and gauges, limited specialty options. |

| Customization | Full bespoke manufacturing, including non-standard dimensions, colors, and specialized anti-climb features. | Limited or no customization beyond standard offerings. |

| Warranty & Support | 20-year limited warranty on galvanized, 15-year on PVC. Dedicated B2B technical support and installation guidance. | Shorter, often ambiguous warranties (5-10 years). Basic customer service. |

| Supply Chain & Lead Time | Optimized supply chain, typically 2-4 week lead time for standard products, 6-8 for custom. Global distribution. | Variable lead times, regional distribution limitations. |

Our commitment extends beyond just product delivery. We pride ourselves on transparent communication, adherence to strict quality control, and an extensive network of experienced professionals to assist with project planning, installation, and after-sales support. This holistic approach ensures that your investment in `chain link fence` delivers maximum long-term value and operational security.

Customized Solutions and Project Engineering

Recognizing that no two projects are identical, we specialize in providing tailored `chain link fence` solutions. Our engineering team works closely with clients to design systems that precisely match unique site requirements, security protocols, and environmental considerations.

Bespoke Design & Fabrication:

- Height and Gauge Adaptation: From specialized 36 chain link fence systems for animal containment to extra-high security barriers, we fabricate custom heights and wire gauges beyond standard offerings. This includes specific mesh sizes for anti-climb or small animal exclusion.

- Coating and Color Customization: While galvanized and green/black PVC are standard, we can match specific RAL colors for branding, aesthetic integration, or camouflage in sensitive landscapes. Specialized protective coatings for extreme conditions (e.g., marine environments, high chemical exposure) are also available.

- Integration with Security Peripherals: Our designs seamlessly integrate with access control systems, CCTV poles, motion sensors, and other electronic security components. Custom post designs and brackets ensure perfect compatibility.

- Gates and Access Points: Design and fabrication of custom swing gates, sliding gates, cantilever gates, and pedestrian access points, all matching the chosen `chain link fence` fabric and robust `chain link fence poles`. Automated gate systems are also part of our custom solutions.

Consultative Engineering Process:

Our process begins with an in-depth consultation to understand the project scope, security objectives, budget, and timeline. This is followed by site assessment, CAD design, material specification, and rigorous quality assurance throughout manufacturing. Our expertise ensures that even complex requirements, such as a large-scale 36 chain link fence project for a national park or high-security fencing for a nuclear facility, are handled with precision.

Application Case Studies: Proven Performance

Case Study 1: Large-Scale Industrial Perimeter Security (Petrochemical Plant)

Client: Major petrochemical refinery in a coastal region.

Challenge: Secure a vast perimeter (15 km) against intrusion while withstanding highly corrosive saline air and potential chemical spills. Standard fencing had a short lifespan due to rapid corrosion.

Solution: We provided a customized 10-foot tall `chain link fence` system, utilizing 9-gauge stainless steel (316L) wire for extreme corrosion resistance, further enhanced with a proprietary marine-grade PVC coating. All `chain link fence poles` and fittings were also made of stainless steel with a specialized protective powder coat. The fence was topped with razor wire for maximum deterrence. The project involved phased delivery and on-site technical support for the installation team.

Outcome: After 5 years, the fence exhibits negligible signs of corrosion, significantly exceeding the lifespan of previous systems. The robust construction and integrated security features have reduced security incidents by 40%, demonstrating long-term cost savings in maintenance and security personnel.

Case Study 2: Public Utility Substation Protection (Urban Environment)

Client: Municipal power utility.

Challenge: Secure numerous urban substations against vandalism and unauthorized access. Fencing needed to be unobtrusive, durable, and cost-effective for deployment across multiple sites, keeping the `chain link fence cost` low while maintaining security.

Solution: We supplied `7 chain link fence` systems, using 11-gauge galvanized steel with a dark green PVC coating to blend with urban landscaping. Small 1.75" mesh was specified to prevent easy climbing. All gates were custom-fabricated with heavy-duty hinges and secure locking mechanisms. Our lead time commitment ensured rapid deployment across 12 sites within a 6-month window.

Outcome: The new fencing has drastically reduced instances of trespassing and vandalism. The aesthetic integration was well-received by local communities, and the low maintenance requirements have led to significant operational savings for the utility company.

Frequently Asked Questions (FAQ)

Q1: What are the key factors to consider when I need to buy chain link fence for industrial use?

A1: For industrial applications, prioritize wire gauge (lower gauge means stronger wire, e.g., 9-gauge or 6-gauge), coating type (hot-dip galvanized or PVC-coated for corrosion resistance), mesh size (smaller for higher security), and the strength of `chain link fence poles` and fittings. Consider adding barbed or razor wire for enhanced deterrence. Your environment (e.g., coastal, chemical exposure) will dictate specific material choices.

Q2: What is the typical service life of your `chain link fence` products?

A2: Our hot-dip galvanized chain link fences typically last 15-20 years, while our premium PVC-coated options can exceed 25 years, often reaching 30 years or more with proper installation and minimal maintenance. This longevity is supported by our adherence to ASTM and ISO standards for material quality and coating thickness.

Q3: Can your `chain link fence` systems be integrated with existing security infrastructure?

A3: Absolutely. Our fencing systems are designed for seamless integration with various security technologies, including CCTV, access control, motion sensors, and intrusion detection systems. We offer custom `chain link fence poles` and brackets to facilitate the mounting of these devices, ensuring a cohesive and effective security perimeter.

Q4: What are the options for a `cheap chain link fence` that still offers reasonable quality for large projects?

A4: For large projects requiring cost-efficiency, we recommend considering standard 11-gauge galvanized `chain link fence` with a 2-inch mesh size. While offering good protection, it balances cost with durability. Opting for knuckled ends instead of twisted also offers a slight cost advantage. We can provide bulk discounts and optimized logistics to further reduce the overall `chain link fence cost` for extensive deployments.

Lead Time, Fulfillment, and Warranty Information

Lead Time & Fulfillment:

Our efficient manufacturing and supply chain management ensure timely delivery. For standard `chain link fence` products, typical lead times range from 2 to 4 weeks, depending on order volume and current production schedules. Custom orders, including specialized heights like 36 chain link fence or unique coating requirements, generally require 6 to 8 weeks for fabrication and delivery. We operate a robust logistics network for national and international shipments, providing detailed tracking and coordinated delivery schedules to minimize project delays. Expedited options are available upon request and project feasibility.

Warranty Commitments:

We stand behind the quality and durability of our products. All our hot-dip galvanized `chain link fence wire` and components come with a 20-year limited warranty against defects in material and workmanship, specifically covering corrosion and structural integrity under normal operating conditions. Our PVC-coated `chain link fence` products are covered by a 15-year limited warranty, guaranteeing resistance to cracking, peeling, and excessive fading. Full warranty details are provided with every order and are available upon request, underscoring our commitment to product longevity and customer satisfaction.

Customer Support & After-Sales Service:

Our dedicated B2B customer support team is available from project conception through installation and beyond. We provide technical consultation, material specification assistance, and post-installation troubleshooting. For any inquiries related to product performance, maintenance, or warranty claims, clients can contact us via phone or email. Our goal is to ensure long-term satisfaction and optimal performance of your investment when you `buy chain link fence` from us.

References

- American Society for Testing and Materials. ASTM A392/A392M-07: Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric. ASTM International, 2007.

- American Society for Testing and Materials. ASTM F668/F668M-17: Standard Specification for Polyvinyl Chloride (PVC) and Other Organic Polymer-Coated Steel Chain-Link Fence Fabric. ASTM International, 2017.

- International Organization for Standardization. ISO 9227:2017: Corrosion tests in artificial atmospheres - Salt spray tests. ISO, 2017.

- Chain Link Fence Manufacturers Institute (CLFMI). Chain Link Fence Industry Report: Market Analysis and Trends. CLFMI, 2023.

- Federal Highway Administration. FHWA-CFL/TD-02-005: Chain-Link Fence for Highway Applications. U.S. Department of Transportation, 2002.

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NewsAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NewsAug.23,2025

-

Garden Edging Fence for Functional and Decorative Landscaping

NewsAug.23,2025

-

3D Wire Mesh Fence for Versatile Security and Decoration

NewsAug.23,2025

Products categories