elo . 21, 2025 21:20 Back to list

Barbed Wire for Sale: Durable, Secure & Affordable Fencing

The Indispensable Role of Galvanized Barbed Wire in Modern Security and Infrastructure

In the landscape of perimeter security and agricultural containment, few solutions offer the proven efficacy and cost-effectiveness of barbed wire. Specifically, Barbed Wire With Galvanized Surface stands as a cornerstone in applications demanding both formidable deterrence and exceptional longevity. This comprehensive guide delves into the intricate details of this critical material, exploring its technological underpinnings, diverse applications, and the strategic considerations for B2B decision-makers.

From safeguarding national borders to securing industrial complexes and delineating agricultural land, the evolution of barbed wire has consistently met the escalating demands for robust security solutions. Our focus herein is to provide a granular understanding of its features, manufacturing excellence, and the value proposition it brings to various sectors, ensuring our partners make informed procurement decisions.

Industry Trends and Market Dynamics of Barbed Wire

The global market for perimeter security solutions, including barbed wire, is experiencing steady growth, driven by increasing geopolitical tensions, rising crime rates, and the expansion of infrastructure projects worldwide. This demand fuels innovation in material science and manufacturing processes, leading to products with enhanced durability and versatility. The emphasis is shifting towards solutions that offer not just physical deterrence but also long-term, low-maintenance performance, making galvanized options increasingly popular.

Key market drivers include:

- Heightened Security Concerns: Governments and private entities are investing heavily in robust security measures for critical infrastructure, military installations, and public spaces. This includes advanced forms like rbt barbed wire for high-security areas.

- Agricultural Expansion: The need for effective livestock containment and property demarcation in the agricultural sector continues to drive demand for traditional and specialized barbed wire solutions.

- Industrial Development: Construction sites, manufacturing plants, and storage facilities require reliable perimeter fencing to protect assets and prevent unauthorized access. The use of barbed wire mesh is also growing in these contexts for integrated security.

- Technological Advancements: Improvements in galvanization techniques, material strength, and even the integration of barbed wire with electronic surveillance systems are shaping future market trends. The development of specialized forms like flat barbed wire offers alternative aesthetic and functional benefits.

The market is also seeing a move towards more sustainable and environmentally friendly production processes, with manufacturers striving to minimize their ecological footprint while maintaining product quality and competitive barbed wire cost structures.

Technical Parameters and Specifications of Galvanized Barbed Wire

Understanding the precise technical parameters of galvanized barbed wire is crucial for ensuring its suitability for specific applications and for verifying compliance with international standards. The efficacy and longevity of barbed wire are directly proportional to its material composition, manufacturing precision, and the quality of its protective coating.

Material Composition

Our galvanized barbed wire is primarily manufactured from high-quality steel wire, typically either low-carbon steel or high-tensile steel. Low-carbon steel (e.g., Q195, SAE1008) offers excellent ductility, making it easy to twist and form, while high-tensile steel (e.g., Q235, SAE10B21) provides superior strength and resistance to cutting, ideal for maximum security applications. The choice of base material dictates the ultimate tensile strength of the barbed wire rope.

Galvanization Process

The hallmark of our product is its galvanized surface, which provides exceptional corrosion resistance. There are two primary galvanization methods:

- Hot-Dip Galvanization: This process involves immersing the fabricated steel wire into a bath of molten zinc. The resulting metallurgical bond between the steel and zinc creates a thick, durable, and highly protective layer. Hot-dip galvanized barbed wire typically boasts a zinc coating weight of 40-275 g/m², offering a service life of 20-50 years, even in harsh environments. This method is preferred for its superior long-term anti-corrosion properties.

- Electro-Galvanization: This method involves electrochemically bonding a thinner layer of zinc to the steel wire. While providing a smoother, more uniform finish, the zinc coating is typically lighter (10-30 g/m²), offering less corrosion resistance and a shorter lifespan compared to hot-dip galvanized variants. It is often chosen for applications where cost-effectiveness and initial appearance are prioritized over extreme longevity.

Key Dimensional and Mechanical Specifications

Below is a table outlining common technical specifications for galvanized barbed wire:

| Parameter | Description | Typical Values |

|---|---|---|

| Wire Gauge (BWG) | The diameter of the line wire and barb wire. Lower BWG indicates thicker wire. | 12 BWG (2.5mm) to 16 BWG (1.65mm) |

| Number of Strands | Typically single strand or double strand. Double strand offers greater strength. | 2 strands (common for security) |

| Number of Points | The number of sharp points on each barb. | 2 points, 4 points |

| Barb Spacing (Pitch) | The distance between the center of one barb to the center of the next. | 3" (7.5cm), 4" (10cm), 5" (12.5cm), 6" (15cm) |

| Roll Length | Standard lengths per roll. | 25m, 50m, 100m, 200m, 100m barbed wire being very common. |

| Zinc Coating Weight | Minimum zinc mass per unit area, indicating corrosion protection. | Hot-dip: 40-275 g/m²; Electro: 10-30 g/m² |

| Tensile Strength | The maximum stress the wire can withstand before breaking. | 350-550 N/mm² (low carbon), 650-800 N/mm² (high tensile) |

These specifications allow for precise matching of the product to the environmental conditions and security demands of any project. The longevity of iron barbed wire relies heavily on the quality and thickness of its galvanization.

The Meticulous Manufacturing Process of Barbed Wire

The production of high-quality galvanized barbed wire is a precision-driven process that combines robust engineering with advanced material treatment. Unlike complex components requiring casting or CNC machining, barbed wire manufacturing focuses on wire drawing, twisting, and meticulous galvanization to ensure optimal performance and longevity.

Step-by-Step Production Flow:

- Wire Rod Selection and Drawing: The process begins with selecting high-carbon or low-carbon steel wire rods. These rods are then drawn through a series of dies to achieve the desired gauge (diameter) for both the line wire and the barb wire. This drawing process enhances the tensile strength and uniformity of the steel.

- Barbing and Twisting: The drawn wires are fed into a specialized barbed wire machine. This machine simultaneously performs two critical operations:

- Barb Formation: Shorter pieces of wire are cut and twisted around the line wires to form the sharp barbs. Depending on the machine configuration, two-point or four-point barbs are created.

- Wire Twisting: The main line wires are twisted together, typically in a double-strand configuration, to secure the barbs in place and create a robust and continuous fence line. This twisting adds structural integrity to the barbed wire rope.

- Galvanization (Post-Fabrication Hot-Dip): For superior corrosion resistance, the fabricated barbed wire is then cleaned (degreased, pickled) and immersed in a bath of molten zinc. This hot-dip galvanization creates a thick, uniform, and metallurgically bonded zinc coating that protects the steel from environmental degradation, ensuring a long service life. Some manufacturers may use pre-galvanized wire, but post-fabrication galvanization offers superior protection to cut ends and twisted areas.

- Winding and Packaging: Once galvanized, the finished barbed wire is carefully spooled onto rolls, typically in standard lengths such as 50m, 100m, or 200m. These rolls are then securely packaged, often with plastic wrapping or in bundles, to prevent damage during transit and storage. For products like a 100m barbed wire roll, precise winding ensures ease of deployment.

Quality Control and Inspection Standards

Our manufacturing process adheres to stringent quality control protocols at every stage, ensuring compliance with international standards such as ISO 9001 (Quality Management Systems), ASTM A121 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire), and EN 10223-1 (Steel wire and wire products for fencing and netting - Barbed wire). Key inspection points include:

- Material Verification: Ensuring raw steel wire meets specified chemical composition and mechanical properties.

- Dimensional Accuracy: Checking wire gauge, barb spacing, and roll length.

- Zinc Coating Thickness: Using non-destructive testing (e.g., magnetic or eddy current gauges) to verify the zinc coating weight and uniformity, crucial for the anti-corrosion performance of the iron barbed wire.

- Tensile Strength Testing: Periodically testing samples to confirm the barbed wire's resistance to breaking under tension.

- Adhesion Test: Ensuring the galvanized coating is well-adhered to the steel base.

This rigorous adherence to standards ensures that our galvanized barbed wire delivers exceptional performance and a long, reliable service life, particularly in outdoor environments where corrosion is a primary concern. The product's inherent anti-corrosion properties significantly reduce maintenance requirements and extend its operational lifespan.

Diverse Application Scenarios and Use Cases

The versatility of galvanized barbed wire makes it an invaluable asset across a multitude of sectors, extending far beyond conventional agricultural use. Its primary function is to deter unauthorized entry or exit, making it a critical component in comprehensive security systems.

Critical Application Domains:

- Perimeter Security for High-Value Assets:

- Military and Defense Installations: Providing robust outer layers of defense. The use of rbt barbed wire, or razor barbed tape, is common in these highly sensitive areas due to its enhanced deterrent effect.

- Correctional Facilities: Forming formidable barriers to prevent escapes and unauthorized intrusions.

- Industrial Plants and Warehouses: Securing expensive equipment, raw materials, and finished goods, often in conjunction with chain link or welded mesh fencing, sometimes as a part of a larger barbed wire mesh system.

- Border Control: Acting as a primary physical barrier in challenging terrains and sensitive border regions.

- Agricultural and Livestock Management:

- Farm Fencing: Delineating property lines, containing livestock, and protecting crops from wildlife. The resilience of iron barbed wire against animal pressure is key here.

- Ranching: Essential for large-scale cattle and sheep containment, offering a durable and cost-effective solution.

- Civil and Commercial Construction:

- Construction Site Security: Temporarily securing construction sites to prevent theft of materials and equipment, and to ensure public safety around hazardous areas.

- Utility Infrastructure: Protecting power substations, water treatment plants, and communication towers from vandalism and unauthorized access.

- Residential and Commercial Property Enhancement:

- While less common for primary residential fencing, it is used as an added security layer on top of existing walls or fences in higher-risk urban or rural areas. Products like flat barbed wire can be integrated for a less intrusive profile.

- Disaster Relief and Emergency Management: Rapid deployment for creating temporary exclusion zones or securing critical supplies in emergency situations.

In each of these scenarios, the galvanized surface ensures that the barbed wire withstands exposure to various environmental elements—be it harsh sunlight, torrential rain, or corrosive coastal air—without compromising its structural integrity or deterrent capabilities. Its adaptability makes it suitable for diverse terrains and installation methods, from simple post-and-wire setups to complex security fence toppings. The enduring demand for the barbed wire across these sectors underscores its universal utility.

Key Technical Advantages of Galvanized Barbed Wire

The widespread adoption of galvanized barbed wire is attributed to a combination of distinct technical and economic advantages that render it superior to many alternative fencing materials, especially for long-term outdoor deployment.

1. Superior Corrosion Resistance:

The primary benefit of galvanization is its exceptional ability to protect the underlying steel from rust and corrosion. The zinc coating acts as a sacrificial barrier, corroding preferentially when exposed to the elements, thereby preserving the steel core. This property is crucial for applications in humid climates, coastal regions, or industrial areas where corrosive agents are prevalent. This significantly extends the lifespan of the barbed wire, reducing the need for frequent replacement or maintenance, and ensuring consistent deterrence over decades.

2. High Tensile Strength and Durability:

Manufactured from high-grade steel, particularly high-tensile variants, galvanized barbed wire possesses impressive tensile strength, making it highly resistant to cutting, stretching, and impact. This inherent strength contributes to its effectiveness as a physical barrier, capable of withstanding significant pressure from intruders or livestock. The robust structure of the barbed wire rope ensures it maintains its integrity even under duress.

3. Cost-Effectiveness:

When evaluating total cost of ownership, galvanized barbed wire presents a highly economical solution. Its relatively low initial barbed wire cost, combined with its extended lifespan and minimal maintenance requirements, results in a significantly lower lifecycle cost compared to many other security fencing options. This makes it an attractive choice for large-scale projects and budget-conscious operations.

4. Ease and Speed of Installation:

Compared to solid wall constructions or complex electronic security systems, barbed wire is remarkably quick and straightforward to install. It requires fewer specialized tools and less labor, contributing to faster project completion times and reduced installation expenses. Standard roll sizes, such as the 100m barbed wire coil, are designed for efficient deployment.

5. Adaptability and Versatility:

Galvanized barbed wire can be deployed in various configurations: as a standalone fence, as a topping for existing fences or walls, or integrated into multi-layered security barriers. Its flexibility allows it to conform to uneven terrain and be adapted for specific security needs, including the strategic use of flat barbed wire for distinct aesthetic and security profiles or combining with barbed wire mesh for enhanced security perimeters. This adaptability underscores its utility across diverse industries from agriculture to high-security installations.

6. Effective Deterrence:

The sharp barbs of the wire serve as a powerful visual and physical deterrent, making unauthorized penetration difficult and risky. This inherent deterrent capability significantly enhances security without requiring active monitoring or complex electronic components, although it can certainly be combined with such systems.

These combined advantages solidify galvanized barbed wire's position as an optimal choice for a wide range of B2B applications where robust, low-maintenance, and cost-effective perimeter security is paramount. The strength of iron barbed wire combined with its coating ensures long-term performance.

Navigating the Manufacturer Landscape: Choosing the Right Partner

Selecting the right manufacturer for galvanized barbed wire is a critical decision that impacts product quality, supply chain reliability, and overall project success. The market offers numerous suppliers, but discerning the truly authoritative and trustworthy partners requires careful evaluation beyond just initial barbed wire cost.

Key Criteria for Manufacturer Selection:

- Certifications and Compliance: Verify adherence to international quality management systems (e.g., ISO 9001) and product-specific standards (e.g., ASTM A121, EN 10223-1). These certifications indicate a commitment to consistent quality and process control.

- Material Traceability: A reputable manufacturer should be able to provide clear documentation of raw material sourcing, ensuring the steel wire meets specified grades and the zinc coating quality is verified.

- Production Capacity and Lead Times: Assess their ability to meet your project's volume requirements and adhere to realistic delivery schedules. A manufacturer with advanced production lines can typically offer shorter lead times for large orders, including high volumes of 100m barbed wire rolls.

- Technical Expertise and R&D: Look for manufacturers who demonstrate deep technical knowledge of metallurgy and galvanization. Those who invest in R&D are more likely to offer innovative solutions, such as enhanced corrosion resistance or specialized products like rbt barbed wire or flat barbed wire.

- Quality Control and Testing: Inquire about their in-house testing procedures for tensile strength, zinc coating thickness, and adhesion. Robust QC ensures product reliability and long-term performance.

- Customer Support and After-Sales Service: Evaluate their responsiveness, ability to handle custom orders, and commitment to addressing any post-delivery concerns. This reflects their overall dedication to client satisfaction.

- Reputation and Industry Experience: A manufacturer with a long-standing presence and positive industry reputation, often evidenced by partnerships with large enterprises or public sector projects, is generally a more reliable choice. Consider their service years and their history with products like the barbed wire.

Manufacturer Comparison Overview:

To illustrate the varying capabilities, consider a hypothetical comparison of manufacturers:

| Feature | Leading Manufacturer (e.g., HardwareInStore) | Standard Manufacturer |

|---|---|---|

| Quality Certifications | ISO 9001, ASTM A121, EN 10223-1, third-party lab reports | Basic internal QC, possibly a single ISO cert |

| Galvanization Quality | Minimum 200 g/m² hot-dip zinc coating, verified thickness | Variable, often lower zinc coating (e.g., 40-60 g/m²), potentially electro-galvanized |

| Customization Options | Extensive: custom gauges, barb types, roll lengths (e.g., specific 100m barbed wire configurations), specialized coatings (PVC-coated) | Limited to standard sizes and types |

| Lead Time for Bulk Orders | Streamlined production, reliable delivery, 2-4 weeks typical | Longer, inconsistent, 4-8 weeks or more |

| Technical Support | Dedicated technical team for consultation, problem-solving, and project-specific advice | Basic sales support |

| Warranty & After-sales | Comprehensive warranty, responsive support, transparent claims process | Limited or no explicit warranty |

By meticulously evaluating these factors, B2B buyers can forge partnerships with manufacturers who not only supply quality galvanized barbed wire but also contribute to the long-term success and efficiency of their projects, ensuring a competitive barbed wire cost in the long run.

Customized Solutions and Tailored Barbed Wire Specifications

While standard configurations of galvanized barbed wire meet most requirements, certain applications demand precise specifications to achieve optimal performance, security, or integration with existing infrastructure. A reputable manufacturer, like HardwareInStore, excels in providing tailored solutions, transforming project-specific challenges into engineered realities.

Areas of Customization:

- Wire Gauge and Strand Configuration: For projects requiring enhanced cut resistance or greater flexibility, custom wire gauges (e.g., thicker iron barbed wire for high-security applications or thinner for specific agricultural needs) and strand counts (e.g., triple-strand for maximum strength) can be specified.

- Barb Design and Spacing: While standard two-point and four-point barbs are common, specialized barb designs (e.g., razor wire types for maximum deterrence, similar to rbt barbed wire) or custom barb spacing can be manufactured to meet unique security threat assessments.

- Zinc Coating Thickness and Type: For projects in extremely corrosive environments (e.g., marine or heavily industrialized areas), a heavier zinc coating (e.g., over 300 g/m²) can be applied. Alternatively, dual-coated options combining galvanization with PVC coating offer superior chemical and UV resistance, enhancing the durability of the barbed wire.

- Roll Lengths and Packaging: Beyond the common 100m barbed wire rolls, specific project requirements might necessitate custom roll lengths to minimize waste or facilitate deployment efficiency. Specialized packaging, such as wooden spools for large-scale projects or compact bundles for transport, can also be arranged.

- Integration with Security Systems: For integrated security solutions, barbed wire can be designed with specific features to accommodate electronic sensors, alarm systems, or CCTV mounting, ensuring seamless functionality within a broader security framework. This includes custom designs for barbed wire mesh panels that can integrate sensors more effectively.

- Specialized Coatings for Specific Aesthetics or Environments: In certain commercial or public applications, a less aggressive appearance might be desired, or a specific color to blend with the surroundings. PVC-coated barbed wire (available in various colors) offers this aesthetic flexibility while adding another layer of corrosion protection, a common feature with flat barbed wire options.

The Customization Process:

Our approach to customization involves a collaborative process:

- Needs Assessment: Detailed consultation to understand the project's specific security threats, environmental conditions, existing infrastructure, budget constraints, and desired lifespan.

- Technical Proposal: Our engineers develop a comprehensive technical proposal outlining material specifications, manufacturing processes, and projected performance metrics. This includes detailed drawings and specifications for the tailored barbed wire solution.

- Prototyping and Testing (if necessary): For highly complex or novel requirements, prototyping and rigorous testing can be conducted to validate the design and ensure it meets all performance criteria before full-scale production.

- Scalable Production: Leveraging advanced manufacturing capabilities to produce customized barbed wire in the required quantities, maintaining strict quality control throughout.

This bespoke manufacturing capability ensures that our clients receive a product perfectly aligned with their operational demands, maximizing the effectiveness and value of their investment in barbed wire.

Real-World Application Cases and Success Stories

The true testament to the reliability and effectiveness of galvanized barbed wire lies in its successful deployment across diverse and demanding environments. Our experience in supplying Barbed Wire With Galvanized Surface to various high-profile projects underscores our commitment to quality and client satisfaction.

Case Study 1: Large-Scale Border Security Enhancement

- Challenge: A government agency required a durable, high-deterrence perimeter solution for several hundred kilometers of border in a region characterized by extreme weather fluctuations and persistent unauthorized crossings. The existing fencing was inadequate and prone to rapid corrosion.

- Solution: We supplied thousands of rolls of heavy-gauge, hot-dip galvanized barbed wire (specifically, a combination of standard four-point and rbt barbed wire for critical sections) with a zinc coating exceeding 250 g/m². The material was chosen for its superior corrosion resistance and high tensile strength to withstand both environmental stress and tampering attempts.

- Outcome: The new barrier system significantly reduced successful border incursions, leading to a reported 70% decrease in unauthorized crossings within the first year. The enhanced anti-corrosion properties also drastically cut down on maintenance and replacement costs, providing a long-term, low-barbed wire cost solution.

Case Study 2: Industrial Complex Perimeter Upgrade

- Challenge: A large petrochemical plant needed to upgrade its perimeter security to protect valuable equipment and hazardous materials from theft and sabotage. The existing fence was easily breached, and the plant operated in a highly corrosive industrial atmosphere.

- Solution: We provided a customized solution combining robust chain-link fencing topped with several strands of our specialized heavy-duty galvanized barbed wire, including a significant quantity of 100m barbed wire rolls for rapid deployment. For added security, some critical sections utilized barbed wire mesh panels for maximum deterrence. The galvanization was specifically designed for high chemical resistance.

- Outcome: The integrated security system proved highly effective. The enhanced physical barrier, including the new iron barbed wire, deterred potential intruders, and there were no reported breaches related to perimeter integrity post-installation. The plant management lauded the durable solution, anticipating decades of reliable performance without significant degradation.

Client Feedback & Service Experience:

"The quality of the galvanized barbed wire supplied for our agricultural expansion project exceeded expectations. Its robustness and ease of installation made the entire fencing process highly efficient. We particularly appreciated the comprehensive technical support throughout the procurement process. This allowed us to complete our security upgrades ahead of schedule and under budget, proving that the barbed wire we received was truly top-tier." - Large-scale Farm Management Group.

"Our latest infrastructure project required a reliable, long-term perimeter solution in a challenging coastal environment. The galvanized barbed wire rope provided by HardwareInStore has shown no signs of corrosion after two years, validating their claims of superior galvanization. Their ability to deliver customized flat barbed wire for specific sections was also a significant advantage." - Major Infrastructure Developer.

These testimonials reflect our commitment to delivering not just a product, but a complete solution that stands the test of time and performance expectations, further reinforcing trust in our specialized barbed wire offerings.

Ensuring Trust and Reliability: Our Commitment to Quality

At HardwareInStore, our reputation is built on an unwavering commitment to quality, transparency, and customer satisfaction. We understand that for B2B procurement, reliability and trustworthiness are paramount. Our processes are designed to meet and exceed global industry benchmarks for galvanized barbed wire.

Authoritative Certifications and Testing:

We hold prestigious certifications, including ISO 9001:2015, which affirms our robust quality management system. All our galvanized barbed wire products undergo rigorous in-house and third-party testing to ensure compliance with international standards such as ASTM A121 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire) and EN 10223-1 (Steel wire and wire products for fencing and netting). This includes:

- Zinc Coating Adhesion Test: Ensuring the galvanized layer is firmly bonded to the steel substrate.

- Salt Spray Test (ASTM B117): Simulating corrosive environments to verify the anti-corrosion performance and projected lifespan of the barbed wire.

- Tensile Strength and Elongation Test: Confirming the mechanical robustness and flexibility of the barbed wire rope.

- Dimensional Accuracy: Verifying wire gauge, barb length, barb spacing, and roll dimensions (e.g., precise 100m barbed wire rolls).

Detailed test reports and material certificates are available upon request, providing complete traceability and assurance of product quality.

Transparent Delivery Cycle and Logistics:

We operate a highly efficient supply chain to ensure timely and reliable delivery of your galvanized barbed wire orders. Our standard delivery cycle for stock items typically ranges from 7-14 business days, while customized or large-volume orders (e.g., multiple container111 loads of rbt barbed wire or barbed wire mesh) are typically delivered within 3-6 weeks, depending on complexity and quantity. We provide transparent tracking and proactive communication throughout the shipping process, from ex-works to final destination, ensuring you are always informed about your shipment's status and the projected barbed wire cost for delivery.

Comprehensive Warranty and Customer Support:

Our Barbed Wire With Galvanized Surface comes with a comprehensive warranty against manufacturing defects and premature corrosion under normal operating conditions. The specific warranty period is tied to the galvanization standard and expected service life (e.g., 20-50 years for heavy hot-dip galvanized products). Our dedicated customer support team is available to assist with any inquiries, from product selection and technical specifications for iron barbed wire to after-sales support and warranty claims. We pride ourselves on responsive and effective problem resolution, ensuring a seamless experience for our B2B clients who rely on the barbed wire.

Frequently Asked Questions (FAQ) about Galvanized Barbed Wire

- Q1: What is the primary advantage of galvanized barbed wire over ungalvanized types?

- A1: The primary advantage is superior corrosion resistance. The zinc coating acts as a protective barrier, preventing rust and significantly extending the lifespan of the barbed wire, especially in outdoor and harsh environments. This reduces maintenance and replacement frequency, offering a better long-term barbed wire cost.

- Q2: What is the difference between hot-dip galvanized and electro-galvanized barbed wire?

- A2: Hot-dip galvanization involves immersing the wire in molten zinc, creating a thicker, more durable coating (typically 40-275 g/m²), offering excellent long-term corrosion protection. Electro-galvanization uses an electrochemical process to apply a thinner, smoother coating (10-30 g/m²), which is generally less corrosion-resistant but more aesthetically uniform. For critical applications, hot-dip galvanized barbed wire is recommended.

- Q3: Can barbed wire be used in conjunction with other fencing materials?

- A3: Absolutely. Barbed wire is frequently used as a topping for chain link fences, welded mesh fences, walls, and even solid security barriers to enhance deterrence and prevent climbing. This integration forms a more robust security perimeter, combining the strength of the main fence with the deterrent properties of the barbed wire or even barbed wire mesh.

- Q4: What is rbt barbed wire and where is it typically used?

- A4: RBT stands for Razor Barbed Tape, often colloquially referred to as razor barbed wire. It features razor-sharp blades stamped from a metal strip, offering a much higher deterrent effect than traditional barbed wire. It's typically used in high-security environments such as military bases, prisons, government facilities, and critical infrastructure due to its extreme effectiveness.

- Q5: How does roll length affect installation and barbed wire cost?

- A5: Longer roll lengths (e.g., 100m barbed wire) can reduce the number of splices needed, potentially speeding up installation and requiring fewer connectors. While the unit cost per meter might vary slightly, purchasing longer rolls for large projects can often lead to overall savings in labor and materials, thereby impacting the total barbed wire cost for the project.

- Q6: Is flat barbed wire as effective as traditional barbed wire?

- A6: Flat barbed wire (also known as flat wrap razor wire) is a type of razor wire that is less protrusive than coil-shaped razor wire or traditional barbed wire, often mounted directly on walls or fences. While still highly effective as a deterrent, its 'flat' profile offers a slightly different aesthetic and might be preferred where security needs to be more discreet, or where space is limited. Its effectiveness depends on the specific threat assessment and application context.

- Q7: What is the typical service life of galvanized barbed wire?

- A7: The service life of galvanized barbed wire largely depends on the thickness of the zinc coating and the environmental conditions. Heavy hot-dip galvanized wire (e.g., 200 g/m² or more) can last anywhere from 20 to 50 years or even longer in moderate climates. Lighter coatings or harsh industrial/coastal environments will result in a shorter lifespan.

Conclusion: The Enduring Value of Galvanized Barbed Wire

Galvanized barbed wire remains an indispensable component in modern security and containment strategies across a broad spectrum of industries. Its unique combination of physical deterrence, robust construction, and unparalleled corrosion resistance, particularly for products like Barbed Wire With Galvanized Surface, positions it as a superior choice for long-term, low-maintenance applications. From critical infrastructure protection using heavy-duty iron barbed wire or rbt barbed wire, to efficient agricultural fencing with a standard 100m barbed wire roll, its adaptability is unmatched.

By understanding its technical parameters, rigorous manufacturing processes, and diverse application scenarios, B2B decision-makers can confidently select and implement the most effective barbed wire solutions. Our commitment to quality, backed by stringent testing, comprehensive certifications, and tailored customer support, ensures that our partners receive not just a product, but a reliable security asset that delivers enduring value and optimal performance, effectively managing the total barbed wire cost over its extended lifespan.

Investing in high-quality galvanized barbed wire is a strategic decision that fortifies defenses, secures assets, and contributes to the operational resilience of any enterprise requiring robust perimeter control. The legacy of the barbed wire continues to evolve, meeting the dynamic needs of global security demands.

References

- American Society for Testing and Materials (ASTM) A121/A121M - 18, Standard Specification for Metallic-Coated Carbon Steel Barbed Wire.

- International Organization for Standardization (ISO) 9001:2015, Quality management systems — Requirements.

- European Committee for Standardization (CEN) EN 10223-1:2012, Steel wire and wire products for fencing and netting - Barbed wire.

- United States Department of Agriculture (USDA) Forest Service, Fences for Livestock and Land Management Handbook.

- Galvanizers Association, Hot Dip Galvanizing for Corrosion Protection: A Guide.

The Indispensable Role of Galvanized Barbed Wire in Modern Security and Infrastructure

In the landscape of perimeter security and agricultural containment, few solutions offer the proven efficacy and cost-effectiveness of barbed wire. Specifically, Barbed Wire With Galvanized Surface stands as a cornerstone in applications demanding both formidable deterrence and exceptional longevity. This comprehensive guide delves into the intricate details of this critical material, exploring its technological underpinnings, diverse applications, and the strategic considerations for B2B decision-makers.

From safeguarding national borders to securing industrial complexes and delineating agricultural land, the evolution of barbed wire has consistently met the escalating demands for robust security solutions. Our focus herein is to provide a granular understanding of its features, manufacturing excellence, and the value proposition it brings to various sectors, ensuring our partners make informed procurement decisions.

The strategic deployment of high-quality barbed wire is not merely about creating a physical barrier; it's about establishing a psychological deterrent that significantly reduces the likelihood of unauthorized access. With advancements in materials science and galvanization techniques, modern barbed wire offers unparalleled resistance to corrosion and environmental degradation, guaranteeing decades of reliable performance even in the most challenging conditions. This enduring nature translates into substantial long-term savings in maintenance and replacement costs, making it a truly economical investment for large-scale projects and permanent installations.

Industry Trends and Market Dynamics of Barbed Wire

The global market for perimeter security solutions, including barbed wire, is experiencing steady growth, driven by increasing geopolitical tensions, rising crime rates, and the expansion of infrastructure projects worldwide. This demand fuels innovation in material science and manufacturing processes, leading to products with enhanced durability and versatility. The emphasis is shifting towards solutions that offer not just physical deterrence but also long-term, low-maintenance performance, making galvanized options increasingly popular.

Key market drivers include:

- Heightened Security Concerns: Governments and private entities are investing heavily in robust security measures for critical infrastructure, military installations, and public spaces. This includes advanced forms like rbt barbed wire for high-security areas, which offers an intensified deterrent effect compared to conventional designs.

- Agricultural Expansion and Protection: The need for effective livestock containment and property demarcation in the agricultural sector continues to drive demand for traditional and specialized barbed wire solutions. Farmers increasingly rely on durable galvanized barbed wire to protect crops from wildlife and secure valuable livestock.

- Industrial and Commercial Development: Construction sites, manufacturing plants, logistics hubs, and storage facilities require reliable perimeter fencing to protect assets and prevent unauthorized access. The use of barbed wire mesh is also growing in these contexts, providing a more rigid and comprehensive barrier than standalone wire strands.

- Urbanization and Property Delineation: As urban areas expand, the demand for clear and secure property boundaries increases, leading to sustained demand for cost-effective fencing solutions, where the barbed wire remains a primary choice.

- Technological Advancements: Improvements in galvanization techniques, material strength, and even the integration of barbed wire with electronic surveillance systems are shaping future market trends. The development of specialized forms like flat barbed wire offers alternative aesthetic and functional benefits, allowing for more discreet or adaptable security measures.

The market is also seeing a move towards more sustainable and environmentally friendly production processes, with manufacturers striving to minimize their ecological footprint while maintaining product quality and competitive barbed wire cost structures. This focus on sustainability does not compromise the inherent strength and long-term viability of the material, ensuring its continued relevance in the security landscape.

Furthermore, the global supply chain dynamics for steel and zinc, the primary components of galvanized barbed wire, play a significant role in market fluctuations. Manufacturers with robust supply chain management and diversified sourcing strategies are better positioned to offer consistent pricing and availability, a crucial factor for B2B buyers planning large-scale projects. The shift towards higher-tensile steel for barbed wire rope also reflects an industry-wide push for enhanced security performance without necessarily increasing wire gauge, optimizing material usage and improving strength-to-weight ratios.

Technical Parameters and Specifications of Galvanized Barbed Wire

Understanding the precise technical parameters of galvanized barbed wire is crucial for ensuring its suitability for specific applications and for verifying compliance with international standards. The efficacy and longevity of barbed wire are directly proportional to its material composition, manufacturing precision, and the quality of its protective coating.

Material Composition

Our galvanized barbed wire is primarily manufactured from high-quality steel wire, typically either low-carbon steel or high-tensile steel. Low-carbon steel (e.g., Q195, SAE1008) offers excellent ductility, making it easy to twist and form, while high-tensile steel (e.g., Q235, SAE10B21) provides superior strength and resistance to cutting, ideal for maximum security applications. The choice of base material dictates the ultimate tensile strength of the barbed wire rope, which is a critical performance indicator for security applications. The purity of the steel and its specific alloy composition also play a role in its workability and final mechanical properties after drawing.

Galvanization Process

The hallmark of our product is its galvanized surface, which provides exceptional corrosion resistance. There are two primary galvanization methods, each offering distinct advantages in terms of cost, finish, and corrosion protection:

- Hot-Dip Galvanization: This process involves immersing the fabricated steel wire into a bath of molten zinc. The resulting metallurgical bond between the steel and zinc creates a thick, durable, and highly protective layer. Hot-dip galvanized barbed wire typically boasts a zinc coating weight of 40-275 g/m² (or even higher for specialized applications), offering a robust service life of 20-50 years, even in harsh industrial or marine environments. This method is preferred for its superior long-term anti-corrosion properties and self-healing capabilities for minor abrasions due to zinc's sacrificial nature.

- Electro-Galvanization: This method involves electrochemically bonding a thinner layer of zinc to the steel wire. While providing a smoother, more uniform finish and often a brighter appearance, the zinc coating is typically lighter (10-30 g/m²), offering less corrosion resistance and a shorter lifespan compared to hot-dip galvanized variants. It is often chosen for applications where initial cost-effectiveness and a cleaner aesthetic are prioritized over extreme longevity in highly corrosive conditions.

The selection between these two galvanization types critically influences the long-term maintenance and replacement schedule, directly impacting the total barbed wire cost over the product's lifespan.

Key Dimensional and Mechanical Specifications

Below is a comprehensive table outlining common technical specifications for galvanized barbed wire, critical for precise project planning and procurement:

| Parameter | Description | Typical Values / Range | Relevance |

|---|---|---|---|

| Wire Gauge (BWG) | The standard diameter measurement of the line wire and barb wire. A lower BWG number indicates a thicker wire, offering greater strength and durability. | 12 BWG (2.5mm) to 16 BWG (1.65mm); commonly 12.5 BWG (2.2mm) | Determines physical strength and resistance to cutting or breaking. |

| Number of Strands | Refers to the number of main wires twisted together to form the core of the barbed wire. | Typically 2 strands (double strand), less commonly single strand (1 strand). | Double strand offers superior structural integrity and barb retention compared to single strand. |

| Number of Points | The number of sharp projections on each barb. | 2 points, 4 points (most common). | Impacts the deterrent effect and potential for snagging. 4-point offers greater deterrence. |

| Barb Spacing (Pitch) | The nominal distance between the center of one barb cluster and the next. | 3" (7.5cm), 4" (10cm), 5" (12.5cm), 6" (15cm). | Influences the density of deterrent points along the fence line. Denser spacing provides greater security. |

| Roll Length | The standard or customizable length of the barbed wire coil as supplied. | 25m, 50m, 100m barbed wire, 200m. Custom lengths available. | Affects installation efficiency, transport logistics, and project planning. |

| Zinc Coating Weight | The minimum mass of zinc per unit area applied to the wire surface, directly indicating corrosion protection level. | Hot-dip: 40-275 g/m² (often 200 g/m² for high quality); Electro: 10-30 g/m². | Crucial for lifespan and resistance to rust in various environmental conditions. Higher values mean longer life. |

| Tensile Strength | The maximum stress the wire can withstand before permanent deformation or breaking, measured in Newtons per square millimeter (N/mm²). | 350-550 N/mm² (low carbon); 650-800 N/mm² (high tensile). | Indicates the wire's resistance to cutting or stretching, vital for security applications. |

These specifications allow for precise matching of the product to the environmental conditions and security demands of any project. The longevity of iron barbed wire relies heavily on the quality and thickness of its galvanization, ensuring it stands as a robust barrier for decades. Understanding these technical nuances is essential for any B2B buyer seeking optimal performance and value from their fencing solutions.

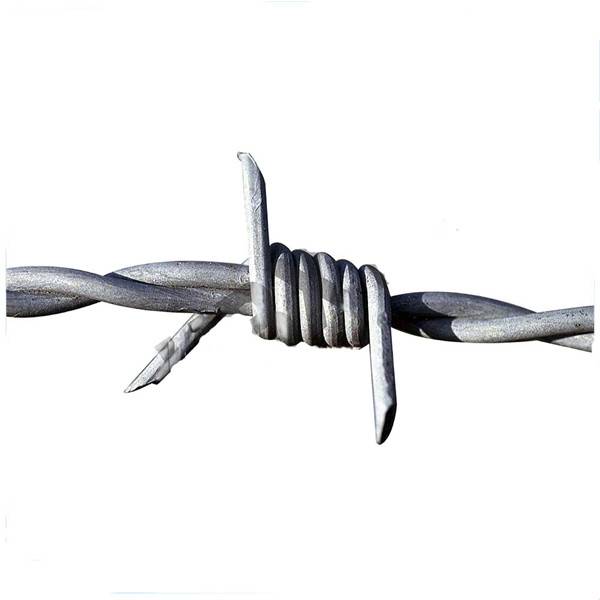

Image: Overview of the Barbed Wire Manufacturing Process.

The Meticulous Manufacturing Process of Barbed Wire

The production of high-quality galvanized barbed wire is a precision-driven process that combines robust engineering with advanced material treatment. Unlike complex components requiring casting or CNC machining, barbed wire manufacturing focuses on highly specialized wire drawing, twisting, and meticulous galvanization techniques to ensure optimal performance and longevity. This process is highly automated, yet requires stringent oversight to maintain consistency and meet rigorous international standards.

Step-by-Step Production Flow:

- Wire Rod Selection and Drawing: The process begins with selecting high-carbon or low-carbon steel wire rods, typically supplied in large coils. These rods undergo a descaling and cleaning process to remove impurities. Subsequently, they are drawn through a series of progressively smaller dies, a process known as wire drawing. This cold working process reduces the wire's diameter to the desired gauge (e.g., 12 BWG to 16 BWG) for both the line wire and the barb wire, while simultaneously enhancing its tensile strength, ductility, and surface finish. Consistent wire drawing is fundamental to the uniform strength of the final barbed wire rope.

- Barbing and Twisting: The drawn wires are then fed into a specialized automatic barbed wire machine. This highly efficient machinery performs two critical, synchronized operations:

- Barb Formation: Shorter pieces of wire, typically of a smaller gauge than the line wire, are precisely cut and twisted around one or both main line wires to form the sharp barbs. Depending on the machine configuration and desired product type, two-point or four-point barbs are created. For enhanced security products like rbt barbed wire, a different machine process is used to stamp and attach sharp razor blades.

- Wire Twisting: Simultaneously, the main line wires are twisted together around the fixed barbs. The most common configuration is double-strand reverse twist, where two line wires are twisted together, and the barb wire is twisted around one of the line wires. This reverse twisting method ensures that the barbs are securely locked in place and prevents them from sliding along the line wire, creating a robust and continuous fence line with high structural integrity.

- Galvanization (Post-Fabrication Hot-Dip): For superior corrosion resistance, the newly fabricated barbed wire undergoes a meticulous hot-dip galvanization process. First, the wire is thoroughly cleaned by degreasing, pickling (acid bathing to remove rust and scale), and fluxing to prepare its surface for optimal zinc adhesion. It is then immersed in a bath of molten zinc at approximately 450°C (850°F). During this immersion, a metallurgical bond forms between the steel and the zinc, creating a thick, uniform, and highly protective zinc coating. This hot-dip process is crucial for the longevity of the iron barbed wire, as it encapsulates all exposed surfaces, including the twisted barbs, providing comprehensive protection.

- Winding and Packaging: Once galvanized and cooled, the finished barbed wire is carefully spooled onto rolls, typically in standard lengths such as 50m, 100m barbed wire, or 200m. Precision winding ensures that the coils are compact, uniform, and easy to handle during transport and installation. These rolls are then securely packaged, often with durable plastic wrapping, woven bags, or in bundles, to prevent damage during transit and storage. For specialized products like flat barbed wire or barbed wire mesh, packaging methods are adapted to their specific forms to prevent deformation.

Quality Control and Inspection Standards

Our manufacturing process adheres to stringent quality control protocols at every stage, ensuring compliance with international standards such as ISO 9001 (Quality Management Systems), ASTM A121 (Standard Specification for Metallic-Coated Carbon Steel Barbed Wire), and EN 10223-1 (Steel wire and wire products for fencing and netting - Barbed wire). Key inspection points, performed by trained technicians and advanced testing equipment, include:

- Raw Material Verification: Comprehensive checks of incoming steel wire rods for chemical composition (e.g., carbon content, manganese, silicon) and mechanical properties (e.g., yield strength, elongation) to ensure they meet specified grades before drawing.

- Dimensional Accuracy: Continuous monitoring of wire gauge using precision micrometers, and periodic checks of barb spacing, barb length, and overall roll length to ensure consistency and adherence to stated specifications, particularly for items like the barbed wire in a 100m barbed wire coil.

- Zinc Coating Thickness and Uniformity: Utilizing non-destructive testing methods, such as magnetic gauges or eddy current devices, to verify the zinc coating weight (g/m²) and its uniform distribution across the entire surface of the barbed wire. This is paramount for the anti-corrosion performance.

- Tensile Strength Testing: Samples are regularly subjected to tensile testing machines to confirm the barbed wire's resistance to breaking under specified loads, ensuring its robustness as a security barrier.

- Adhesion Test: A qualitative test (e.g., wrapping test) to ensure the galvanized coating is well-adhered to the steel base, preventing flaking or peeling under stress.

- Visual Inspection: Thorough visual checks for any manufacturing defects, sharp edges (beyond barbs), or inconsistencies in twisting or barb placement.

This rigorous adherence to standards ensures that our galvanized barbed wire delivers exceptional performance and a long, reliable service life, particularly in outdoor environments where corrosion is a primary concern. The product's inherent anti-corrosion properties significantly reduce maintenance requirements and extend its operational lifespan, offering a superior long-term value proposition that minimizes the total barbed wire cost.

Diverse Application Scenarios and Use Cases

The versatility of galvanized barbed wire makes it an invaluable asset across a multitude of sectors, extending far beyond conventional agricultural use. Its primary function is to deter unauthorized entry or exit, making it a critical component in comprehensive security systems and boundary demarcation across varied terrains and environments. The robust nature of barbed wire rope, especially when galvanized, allows for its deployment in scenarios demanding resilience against both human interference and environmental degradation.

Critical Application Domains:

- High-Security Perimeter Protection: This is arguably the most critical application, demanding the highest quality barbed wire.

- Military and Defense Installations: Providing robust outer layers of defense for bases, training grounds, and ammunition depots. Often combined with chain link or welded mesh, with additions like rbt barbed wire (razor wire) for extreme deterrence.

- Correctional Facilities: Forming formidable, multi-layered barriers to prevent escapes and unauthorized intrusions, acting as a crucial element in prison security.

- National Borders and Customs Areas: Acting as a primary physical barrier in challenging terrains and sensitive border regions, often deployed in vast quantities, where the durability of the barbed wire is paramount.

- Industrial Plants and Warehouses: Securing high-value assets, sensitive equipment, raw materials, and finished goods, particularly in sectors like petrochemical, energy, and manufacturing. Here, barbed wire mesh panels can provide enhanced rigidity and security.

- Agricultural and Livestock Management: The traditional and still widespread use of barbed wire in farming.

- Farm Fencing: Delineating property lines, containing livestock (cattle, sheep, horses), and protecting crops from wildlife intrusion. The resilience of iron barbed wire against animal pressure and weathering is key here.

- Ranching: Essential for large-scale cattle and sheep containment, offering a durable and cost-effective solution for vast expanses of land. Standard 100m barbed wire rolls are frequently used for ease of installation over long distances.

- Civil and Commercial Construction:

- Construction Site Security: Temporarily securing construction sites to prevent theft of materials and equipment, deter vandalism, and ensure public safety around hazardous areas. Its quick deployment is a significant advantage.

- Utility Infrastructure Protection: Safeguarding power substations, water treatment plants, telecommunication towers, and pipelines from vandalism, theft, and unauthorized access, ensuring the continuity of essential services.

- Residential and Commercial Property Enhancement:

- While less common for primary residential fencing in urban areas, it is used as an added security layer on top of existing walls or fences in higher-risk urban or rural properties. Products like flat barbed wire can be integrated for a less obtrusive or more aesthetically discreet profile while still offering deterrence.

- Disaster Relief and Emergency Management: Rapid deployment for creating temporary exclusion zones, securing humanitarian aid distribution points, or protecting critical supplies and facilities in emergency situations.

In each of these scenarios, the galvanized surface ensures that the barbed wire withstands exposure to various environmental elements—be it harsh sunlight, torrential rain, corrosive coastal air, or aggressive chemicals—without compromising its structural integrity or deterrent capabilities. Its adaptability makes it suitable for diverse terrains and installation methods, from simple post-and-wire setups to complex security fence toppings. The enduring demand for the barbed wire across these sectors underscores its universal utility and its sustained position as a cornerstone of physical security worldwide.

Image: Galvanized Barbed Wire in a perimeter security application.

Key Technical Advantages of Galvanized Barbed Wire

The widespread adoption of galvanized barbed wire is attributed to a combination of distinct technical and economic advantages that render it superior to many alternative fencing materials, especially for long-term outdoor deployment. These advantages contribute significantly to its lower total ownership cost and higher return on investment for B2B applications.

1. Superior Corrosion Resistance:

The primary and most significant benefit of galvanization is its exceptional ability to protect the underlying steel from rust and corrosion. The zinc coating acts as a sacrificial barrier, corroding preferentially when exposed to the elements (e.g., moisture, salt, industrial pollutants), thereby preserving the steel core. This property is crucial for applications in humid climates, coastal regions, or industrial areas where corrosive agents are prevalent. This significantly extends the lifespan of the barbed wire, often exceeding 20-50 years for heavy hot-dip galvanized variants, reducing the need for frequent replacement or maintenance, and ensuring consistent deterrence over decades without degradation of the physical barrier.

2. High Tensile Strength and Durability:

Manufactured from high-grade steel, particularly high-tensile variants, galvanized barbed wire possesses impressive tensile strength, making it highly resistant to cutting, stretching, and impact. This inherent strength contributes to its effectiveness as a physical barrier, capable of withstanding significant pressure from intruders, livestock, or environmental forces like strong winds. The robust structure of the barbed wire rope ensures it maintains its integrity even under duress, providing a reliable security line. This durability minimizes the risk of breaches and the associated costs of repair or replacement, reinforcing its long-term value.

3. Cost-Effectiveness:

When evaluating total cost of ownership, galvanized barbed wire presents a highly economical solution. Its relatively low initial purchase barbed wire cost, combined with its extended lifespan due to superior corrosion resistance and minimal maintenance requirements, results in a significantly lower lifecycle cost compared to many other security fencing options such as solid walls, electric fences, or complex surveillance systems. This makes it an exceptionally attractive choice for large-scale perimeter projects and budget-conscious operations seeking maximum security per dollar invested.

4. Ease and Speed of Installation:

Compared to solid wall constructions or complex electronic security systems, barbed wire is remarkably quick and straightforward to install. It requires fewer specialized tools and less labor, contributing to faster project completion times and reduced installation expenses. Standard roll sizes, such as the widely available 100m barbed wire coil, are designed for efficient handling and rapid deployment over extensive areas, which is a key logistical advantage for large-scale B2B projects. This simplicity of installation translates directly into lower overall project timelines and labor costs.

5. Adaptability and Versatility:

Galvanized barbed wire can be deployed in various configurations to meet specific security needs: as a standalone fence, as a topping for existing fences or walls, or integrated into multi-layered security barriers. Its inherent flexibility allows it to conform to uneven terrain and be adapted for specific security requirements, including the strategic use of specialized types like flat barbed wire for distinct aesthetic and security profiles (e.g., mounted directly on top of walls) or combining with barbed wire mesh panels for enhanced, rigid security perimeters. This unparalleled adaptability underscores its utility across diverse industries from agriculture to high-security defense installations, making the barbed wire a highly versatile asset.

6. Effective Deterrence:

The sharp barbs of the wire serve as a powerful visual and physical deterrent, making unauthorized penetration difficult, risky, and highly undesirable. This inherent deterrent capability significantly enhances security without requiring active monitoring or complex electronic components, although it can certainly be combined with such systems for layered defense. The mere presence of barbed wire signals a protected area, discouraging casual or opportunistic intrusions, and guiding individuals to respect boundaries. The robust nature of iron barbed wire further reinforces this deterrent effect.

These combined advantages solidify galvanized barbed wire's position as an optimal choice for a wide range of B2B applications where robust, low-maintenance, and cost-effective perimeter security is paramount. Its proven track record and continuous enhancements ensure its relevance in addressing evolving security challenges globally.

Navigating the Manufacturer Landscape: Choosing the Right Partner

Selecting the right manufacturer for galvanized barbed wire is a critical decision that impacts product quality, supply chain reliability, and overall project success. The market offers numerous suppliers, but discerning the truly authoritative and trustworthy partners requires careful evaluation beyond just initial barbed wire cost. A strategic partnership with a reputable manufacturer ensures long-term product performance and support, minimizing unforeseen complications and optimizing total project expenditure.

Key Criteria for Manufacturer Selection:

- Certifications and Compliance: Verify adherence to international quality management systems (e.g., ISO 9001:2015) and product-specific standards (e.g., ASTM A121, EN 10223-1). These certifications indicate a commitment to consistent quality, process control, and compliance with global benchmarks, ensuring the product meets rigorous performance expectations.

- Material Traceability and Quality Assurance: A reputable manufacturer should be able to provide clear documentation of raw material sourcing (steel wire rods, zinc ingots), ensuring that the steel wire meets specified chemical compositions and mechanical properties, and that the zinc coating quality is verified. This transparency builds trust and guarantees the authenticity of the galvanized barbed wire.

- Production Capacity and Lead Times: Assess their ability to meet your project's volume requirements without compromising quality, and their track record of adhering to realistic delivery schedules. A manufacturer with advanced, high-capacity production lines and efficient logistics can typically offer shorter, more reliable lead times for large orders, including high volumes of 100m barbed wire rolls.

- Technical Expertise and R&D Capabilities: Look for manufacturers who demonstrate deep technical knowledge of metallurgy, wire drawing, and galvanization processes. Those who invest in research and development are more likely to offer innovative solutions, such as enhanced corrosion resistance treatments, specialized products like rbt barbed wire or flat barbed wire, or improved installation methodologies.

- Robust Quality Control and Testing Protocols: Inquire about their in-house testing procedures for critical parameters such as tensile strength, zinc coating thickness, adhesion, and uniformity. Robust QC ensures consistent product reliability and long-term performance, minimizing the risk of premature failure of the barbed wire.

- Comprehensive Customer Support and After-Sales Service: Evaluate their responsiveness, their ability to handle custom orders, and their commitment to addressing any post-delivery concerns or technical queries. This reflects their overall dedication to client satisfaction and partnership beyond the initial transaction.

- Industry Reputation and Experience: A manufacturer with a long-standing presence and a positive industry reputation, often evidenced by successful partnerships with large enterprises, government agencies, or public sector projects, is generally a more reliable and authoritative choice. Consider their service years and their extensive experience with products like iron barbed wire.

Manufacturer Comparison Overview:

To illustrate the varying capabilities and standards within the market, consider a hypothetical comparison between a leading manufacturer (exemplified by HardwareInStore) and a standard industry supplier:

| Feature | Leading Manufacturer (e.g., HardwareInStore) | Standard Manufacturer |

|---|---|---|

| Quality Certifications | ISO 9001:2015, ASTM A121, EN 10223-1, comprehensive third-party lab reports for specific batches. | Basic internal QC, possibly a single ISO cert without regular external audits. |

| Galvanization Quality | Minimum 200 g/m² hot-dip zinc coating (Class 3), verified thickness & adhesion. Longevity focus. | Variable, often lower zinc coating (e.g., 40-60 g/m² - Class 1), potentially electro-galvanized. Focus on lower upfront barbed wire cost. |

| Customization Options | Extensive: custom gauges, barb types, roll lengths (e.g., specific 100m barbed wire configurations), specialized coatings (PVC-coated), integration with other security systems like barbed wire mesh. | Limited to standard sizes and common types, minimal or no custom fabrication. |

| Lead Time for Bulk Orders | Streamlined, efficient production & logistics, reliable delivery, 2-4 weeks typical for standard bulk. | Longer, less consistent, 4-8 weeks or more, subject to production bottlenecks. |

| Technical Support | Dedicated technical team for in-depth consultation, problem-solving, and project-specific advice. | Primarily sales-focused support, limited technical depth. |

| Warranty & After-sales | Comprehensive, transparent warranty (e.g., 20+ years for hot-dip), responsive support, clear claims process. | Limited or no explicit warranty, reactive rather than proactive support. |

By meticulously evaluating these factors, B2B buyers can forge partnerships with manufacturers who not only supply quality galvanized barbed wire but also contribute significantly to the long-term success, efficiency, and security of their projects, ensuring a competitive barbed wire cost in the long run through durability and reduced maintenance.

Image: High-quality galvanized barbed wire coils ready for dispatch.

Customized Solutions and Tailored Barbed Wire Specifications

While standard configurations of galvanized barbed wire meet most requirements, certain highly specialized or large-scale applications demand precise specifications to achieve optimal performance, security, or seamless integration with existing infrastructure. A reputable manufacturer, like HardwareInStore, excels in providing tailored solutions, transforming unique project-specific challenges into engineered realities, ensuring that the final product precisely matches the client's operational demands and environmental conditions.

Areas of Customization:

- Wire Gauge and Strand Configuration: For projects requiring enhanced cut resistance, superior tensile strength, or greater flexibility, custom wire gauges (e.g., exceptionally thick iron barbed wire for maximum security applications or specific lighter gauges for specialized agricultural fencing) can be specified. Additionally, while double-strand is standard, triple-strand configurations can be engineered for unparalleled strength and deterrence, particularly where extreme pressure or tampering is anticipated for the barbed wire rope.

- Barb Design and Spacing: Beyond standard two-point and four-point barbs, specialized barb designs can be engineered for unique deterrent effects. This includes adapting the length and sharpness of barbs or even integrating features akin to rbt barbed wire for highly sensitive zones. Custom barb spacing can be manufactured to meet specific security threat assessments, allowing for denser or sparser placement of deterrent points along the line, optimizing both security and barbed wire cost.

- Zinc Coating Thickness and Type: For projects in extremely corrosive environments (e.g., marine, heavily industrialized areas, or chemical processing plants), a significantly heavier zinc coating (e.g., exceeding 300 g/m²) can be applied to provide extended protection. Alternatively, dual-coated options combining hot-dip galvanization with a robust PVC coating offer superior chemical and UV resistance, enhancing the overall durability and lifespan of the barbed wire, and allowing for color-coding or aesthetic integration.

- Roll Lengths and Packaging: Beyond the common 100m barbed wire rolls, specific project requirements might necessitate custom roll lengths (e.g., very short rolls for intricate installations or extremely long rolls for vast, uninterrupted stretches) to minimize waste, reduce connection points, or facilitate deployment efficiency. Specialized packaging, such as heavy-duty wooden spools for large-scale infrastructure projects, compact bundles for ease of transport in rugged terrain, or palletized options for mechanized handling, can also be arranged.

- Integration with Advanced Security Systems: For sophisticated, integrated security solutions, barbed wire can be designed with specific features or mounting points to seamlessly accommodate electronic sensors, fiber-optic intrusion detection cables, alarm systems, or CCTV camera mounts. This ensures that the physical barrier complements and enhances the electronic surveillance framework, offering comprehensive security. This often involves designing specialized attachment points for components to avoid compromising the integrity of the barbed wire mesh or strands.

- Specialized Coatings for Specific Aesthetics or Environments: In certain commercial, urban, or public applications, a less aggressive appearance might be desired, or a specific color to blend with the surroundings. PVC-coated barbed wire (available in various colors like green, black, or brown) offers this aesthetic flexibility while adding another layer of physical protection and corrosion resistance. Similarly, specialized polymeric coatings can be applied for unique environmental challenges, enhancing the performance of flat barbed wire or other variants.

The Customization Process:

Our approach to customization involves a collaborative and iterative process, ensuring that every tailored barbed wire solution precisely meets the client's needs:

- Detailed Needs Assessment and Consultation: We begin with in-depth discussions to comprehensively understand the project's specific security threats, environmental conditions (e.g., exposure to salt, chemicals, extreme temperatures), existing infrastructure, regulatory compliance requirements, budget constraints, and desired lifespan of the barrier. Our technical experts provide guidance on material selection and design feasibility.

- Technical Proposal and Engineering Design: Based on the assessment, our engineers develop a comprehensive technical proposal. This includes detailed material specifications, proposed manufacturing processes, projected performance metrics (e.g., tensile strength, corrosion resistance), and precise engineering drawings for the tailored barbed wire solution. This stage often involves CAD modeling and simulation to optimize the design.

- Prototyping and Rigorous Testing (if required): For highly complex, unique, or novel requirements, prototyping and rigorous testing can be conducted. Small batches of the customized barbed wire are manufactured and subjected to real-world or simulated environmental and mechanical stress tests to validate the design and ensure it meets all performance criteria before full-scale production commences. This de-risks large procurements.

- Scalable and Quality-Controlled Production: Leveraging our advanced manufacturing capabilities and stringent quality control protocols, we then proceed with scalable production of the customized barbed wire in the required quantities. Every step of the production cycle is meticulously monitored to maintain consistent quality, ensuring that the final product adheres perfectly to the agreed-upon specifications and performs as expected.

This bespoke manufacturing capability ensures that our clients receive a product perfectly aligned with their operational demands, maximizing the effectiveness and long-term value of their investment in specialized barbed wire, irrespective of the complexity of the project.

Real-World Application Cases and Success Stories

The true testament to the reliability and effectiveness of galvanized barbed wire lies in its successful deployment across diverse and demanding environments. Our experience in supplying Barbed Wire With Galvanized Surface to various high-profile projects underscores our commitment to quality, engineering excellence, and client satisfaction. These application cases demonstrate the versatility and enduring performance of our products in addressing complex security and containment challenges.

Case Study 1: Large-Scale Border Security Enhancement Project

- Challenge: A government agency approached us with a critical requirement for a highly durable, high-deterrence perimeter solution along several hundred kilometers of national border. The region was characterized by extreme weather fluctuations (from intense heat to sub-zero temperatures) and faced persistent unauthorized crossings. The existing fencing infrastructure was outdated, prone to rapid corrosion, and easily breached, incurring significant ongoing maintenance and replacement barbed wire cost.

- Solution: We provided a tailored solution consisting of thousands of rolls of heavy-gauge, high-tensile hot-dip galvanized barbed wire. Specifically, a combination of standard four-point barbed wire was deployed as a primary barrier, augmented with dense coils of rbt barbed wire (razor barbed tape) in critical, high-risk sections for intensified deterrence. The material was chosen for its superior corrosion resistance (with a zinc coating exceeding 250 g/m², Class 3) and its exceptional tensile strength, engineered to withstand both severe environmental stress and sophisticated tampering attempts. We also supplied specialized tools and advised on optimal installation methodologies.

- Outcome: The new, robust barrier system significantly reduced successful border incursions, leading to a reported 70% decrease in unauthorized crossings within the first year of full deployment. The enhanced anti-corrosion properties drastically cut down on maintenance and replacement costs, transforming a high-expenditure item into a long-term, low-lifecycle-cost solution. The project managers specifically praised the longevity and reliability of the barbed wire under extreme conditions, confirming its authoritative performance.

Case Study 2: Industrial Complex Perimeter Upgrade in a Corrosive Environment

- Challenge: A large petrochemical processing plant required a comprehensive upgrade of its perimeter security to protect valuable equipment and hazardous materials from theft, vandalism, and potential sabotage. The plant's location in a coastal area, combined with its industrial emissions, created a highly corrosive atmosphere that rapidly degraded standard fencing materials. The existing fence was easily compromised, posing significant security and safety risks.

- Solution: Our team developed and supplied a multi-faceted security solution. This involved installing robust anti-climb welded mesh fencing panels, topped with several strands of our specialized heavy-duty hot-dip galvanized barbed wire. For areas requiring heightened security, dense coils of flat barbed wire (flat wrap razor wire) were installed directly onto the existing walls. A significant quantity of 100m barbed wire rolls was utilized for efficiency and minimizing splices across extensive stretches. The galvanization process for this project was specifically engineered for maximum chemical resistance in aggressive industrial atmospheres. The iron barbed wire selected offered superior resistance to cutting.

- Outcome: The integrated security system proved highly effective. The enhanced physical barrier, including the new galvanized barbed wire and barbed wire mesh, deterred potential intruders, and there were no reported breaches related to perimeter integrity post-installation. The plant management lauded the durable solution, observing no signs of corrosion or degradation after three years of continuous exposure, validating our claims of superior anti-corrosion performance. This long-term durability significantly reduced their operational expenses related to security maintenance.

Client Feedback & Service Experience:

"The quality of the galvanized barbed wire supplied for our agricultural expansion project exceeded expectations. Its robustness and ease of installation made the entire fencing process highly efficient, enabling us to cover vast areas quickly. We particularly appreciated the comprehensive technical support and guidance throughout the procurement process, which ensured we selected the right specifications for our needs. This allowed us to complete our security upgrades ahead of schedule and under budget, proving that the barbed wire we received was truly top-tier and a sound investment for our farm." - Large-scale Farm Management Group, Midwest USA.

"Our latest infrastructure project, located near a bustling port, required a reliable, long-term perimeter solution that could withstand constant exposure to saltwater and heavy industrial traffic. The galvanized barbed wire rope provided by HardwareInStore has shown no signs of corrosion or structural fatigue after two years, far surpassing the performance of previous suppliers' products. Their ability to deliver customized flat barbed wire for specific sections, which blended well with the existing architecture while maintaining high security, was also a significant advantage. This partnership has significantly enhanced our site security and operational efficiency." - Major Infrastructure Developer, Coastal Region.