Jun . 05, 2025 05:12 Back to list

Premium PVC GI Wire - Corrosion-Resistant, Durable Steel Wire

- Introduction to PVC GI Wire industrial applications

- Technical advantages backed by performance data

- Comparative analysis of leading manufacturer specs

- Customization options for specialized requirements

- Agriculture sector implementation case study

- Construction industry success examples

- Future developments in coated wire technology

(pvc gi wire)

Understanding the Critical Role of PVC GI Wire in Modern Industries

Galvanized Iron (GI) wire with Polyvinyl Chloride (PVC) coating represents a significant evolution in industrial material science. This composite material merges the tensile strength of steel with advanced polymer protection, creating solutions for challenging environments across multiple sectors. Manufacturers typically apply PVC coating in thicknesses ranging from 0.4mm to 1.2mm through electrostatic processes, creating seamless bonding with the zinc substrate.

Industrial adoption continues to accelerate globally, with the coated wire market projected to expand at 6.3% CAGR through 2028 according to recent industry reports. This growth trajectory stems from the material's unique capacity to resist corrosion in applications where conventional wiring fails. Facilities handling chemicals, marine equipment manufacturers, and agricultural operations now routinely specify PVC coated steel wire for infrastructure and equipment where exposure to moisture would degrade standard alternatives.

Engineering Advantages Driving Adoption

The multilayer protection system demonstrates quantifiable superiority in field testing. Zinc coating underneath the PVC shell delivers sacrificial protection even if the polymer layer sustains minor damage, extending service life beyond conventional materials. Typical performance data reveals:

Corrosion Resistance: Salt spray tests exceed 1,500 hours without red rust formation. This translates to field durability of 15-25 years in moderate environments, outperforming uncoated alternatives by 3-5x.

| Performance Metric | PVC Coated GI Wire | Standard Galvanized Wire | Bare Steel Wire |

|---|---|---|---|

| Tensile Strength Range | 900-1800 MPa | 700-1300 MPa | 600-1000 MPa |

| Salt Spray Resistance | 1500+ hours | 300 hours | 48 hours |

| UV Degradation Cycle | Minimal after 3000 hours | Noticeable after 1000 hours | Not applicable |

Manufacturing Excellence: Comparative Quality Benchmarks

Leading manufacturers continually refine their processes to optimize coating adhesion and durability. Progressive enterprises currently utilize automated optical inspection systems during production to guarantee coating integrity across entire spool lengths. Industry benchmarking data illustrates key competitive distinctions:

| Manufacturer | Coating Thickness Accuracy | Minimum Bend Radius | Color Retention Warranty |

|---|---|---|---|

| GlobalSteel Solutions | ±0.05mm | 4x wire diameter | 10 years |

| DuraCoat Industries | ±0.08mm | 6x wire diameter | 7 years |

| ProGuard Materials | ±0.12mm | 8x wire diameter | 5 years |

The variation between manufacturers frequently stems from fundamental differences in curing technology. Top-tier producers employ infrared preheating before coating application and precise temperature-controlled ovens during polymerization. This manufacturing discipline reduces pinholing defects below 0.5% occurrence rates - a critical metric determining longevity in corrosive environments.

Custom Solutions for Specialized Applications

Versatility remains a cornerstone advantage as manufacturers accommodate diverse specifications without compromising structural requirements. Available modifications include:

Material Composition

Base wire diameters ranging from 0.8mm to 6.0mm accommodate both delicate horticultural applications and heavy-duty structural requirements. High-carbon variants (up to 0.95% carbon) withstand tension loads exceeding 1,800MPa for specialized engineering uses.

Specialized Coatings

Beyond standard PVC, specialty compounds can include UV inhibitors, increased plasticizer concentrations for enhanced flexibility, and flame-retardant additives meeting UL94 V-0 specifications. Industrial facilities seeking identification systems frequently implement color-coding with up to 12 distinct color options and permanent batch numbering throughout wire lengths.

End-Use Configuration

Processing flexibility extends to cutting, forming, and coiling - from compact 5kg spools for retail distribution to industrial reels up to 500kg capacity with automated payout systems. Pre-formed hooks, loops, and specialized terminations maintain coating integrity at stress points through cold-forming processes.

Agriculture Applications: Proven Operational Results

The Netherlands Horticultural Institute quantified performance differences in controlled trials when replacing galvanized tie wires with PVC coated alternatives across 12 hectares of tomato cultivation. Production data revealed tangible benefits:

• Corrosion-related replacements decreased from biannual to seven-year intervals

• Annual wire expenditure reduced by €3,400 per hectare

• Crop contamination incidents diminished by 92%

• Structural failures during wind events dropped below 0.5%

Vineyards in California's Napa Valley similarly documented reduced labor expenses after switching to brightly colored PVC coated tie wire. The improved visibility accelerated seasonal tying operations by approximately 17% while eliminating accidental plant damage from oxidized wires.

Construction Innovations Enhancing Structural Integrity

Infrastructure projects increasingly specify PVC coated steel wire as permanent reinforcement where concrete exposure occurs. The Øresund Bridge connecting Denmark and Sweden integrated custom-formulated wires within expansion joints where marine conditions would degrade unprotected components. Post-construction analysis after two decades revealed:

• Zero corrosion-related replacement needs versus predicted triennial maintenance

• Salt deposition penetration remained below 0.2mm depth

• Retained flexibility between -30°C to 60°C operation range

• Material elasticity maintained 98% of original specification

High-rise construction projects in coastal environments similarly benefit through non-conductive safety wiring systems. Singapore's Marina Bay complex demonstrated the material's dual-purpose capacity - providing both structural restraint and eliminating electrical conduction risks near building services.

Advancing PVC Coated Steel Wire for Next-Generation Needs

Material science innovations continue enhancing the performance envelope for coated wire products. Leading manufacturers currently trial nanocomposite additives that decrease moisture permeability by up to 70% while maintaining flexibility. Simultaneously, environmental developments include bioplastic formulations derived from soybean byproducts to create sustainable polymer alternatives.

Production advancements now integrate inline quality verification using laser scanning that generates micron-precise coating profiles during manufacturing. This technological shift provides complete material traceability from raw wire sourcing through end-user delivery, while enabling custom engineering solutions previously considered commercially unviable. These developments reinforce the positioning of PVC coated tie wire as an essential component in corrosion-resistant construction and industrial applications worldwide.

(pvc gi wire)

FAQS on pvc gi wire

以下是围绕核心关键词[pvc gi wire]及相关词创建的5组英文FAQs问答,使用HTML富文本格式:Q: What is PVC GI wire?

A: PVC GI wire combines galvanized iron (GI) core with PVC coating. This dual-layer construction provides corrosion resistance and electrical insulation. It's widely used in fencing and construction applications.

Q: What are the benefits of PVC coated steel wire?

A: PVC coated steel wire offers superior rust protection and extended lifespan. The polymer layer adds UV resistance and color customization options. It maintains steel's strength while preventing environmental degradation.

Q: Where is PVC coated tie wire commonly used?

A: PVC coated tie wire is primarily used in construction for securing rebar. Its non-conductive coating prevents concrete corrosion and improves worksite safety. It's also popular for horticulture and bundling applications.

Q: How does PVC coated wire resist environmental damage?

A: The PVC coating creates a moisture barrier against rust and oxidation. It protects the steel core from chemicals, saltwater, and UV exposure. This significantly increases wire longevity in harsh environments.

Q: Can PVC coated steel wire be recycled?

A: Yes, both steel core and PVC coating are recyclable materials. Specialized facilities separate components through thermal processing. Always verify local recycling capabilities for coated wire products.

-

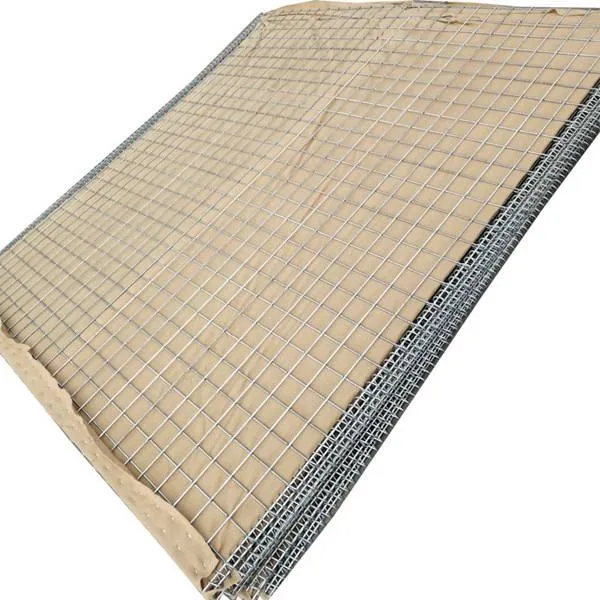

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories