Jun . 01, 2025 12:19 Back to list

Heavy Welded Wire Mesh Durable & High-Strength Solutions

- Introduction to Heavy Welded Wire Mesh: Strength and Applications

- Technical Superiority and Data-Backed Performance

- Leading Manufacturers: A Comparative Analysis

- Customization: Tailoring to Specific Project Needs

- Installation Best Practices for Longevity

- Real-World Applications: Success Stories

- Conclusion: Why Heavy Duty Welded Wire Mesh Panels are Essential

(heavy welded wire mesh)

Introduction to Heavy Welded Wire Mesh: Strength and Applications

Heavy welded wire mesh represents the industrial-grade solution for structural reinforcement and security applications where standard wire fabrics prove inadequate. These galvanized steel grids are engineered with diameters exceeding 6mm and aperture sizes ranging from 50mm to 200mm to withstand immense forces. Construction engineers specify heavy welded wire mesh

panels for concrete slab reinforcement, machine guarding systems, and material handling equipment due to their exceptional yield strength – typically 1000 MPa or higher. The precision-resistance welding technique creates uniform intersections that distribute impact forces across the entire panel structure.

Industrial operations increasingly select heavy duty welded wire mesh over expanded metal or perforated sheets where structural integrity is non-negotiable. Waste management facilities use them as shredder screens capable of enduring tonnes of metal scrap impact daily. Port authorities install them as heavy duty welded mesh barriers along cargo terminals where shipping containers might collide with perimeter systems. Unlike woven alternatives, the rigid welded connections prevent unraveling when wires are cut during installation. This robustness extends service life significantly, with properly maintained installations delivering 25+ years of performance even in corrosive saltwater environments.

Technical Superiority and Data-Backed Performance

The mechanical properties of heavy welded wire mesh are quantified through rigorous international testing protocols. Independent laboratories consistently document tensile strengths ranging from 800-1200 MPa depending on wire alloy composition. Corrosion resistance tests reveal that hot-dip galvanized mesh maintains structural integrity after 1,500 hours of salt spray exposure, outperforming electroplated alternatives by 300%.

Material science breakthroughs have further enhanced performance characteristics. Modern heavy duty welded wire mesh panels incorporate controlled thermal treatments that modify crystalline steel structures to increase hardness without compromising flexibility. Fatigue resistance testing shows that these panels withstand over 10 million load cycles at 75% of their rated maximum load capacity. Weld point integrity undergoes destructive testing, revealing that joints maintain cohesion up to 95% of the wire's tensile strength. These technical advantages translate directly to real-world durability – field data from mining operations indicates impact resistance against 35kg rocks dropped from 10-meter heights without panel deformation.

Leading Manufacturers: A Comparative Analysis

| Manufacturer | Wire Gauge Range | Max Panel Dimensions | Galvanization Class | Yield Strength | Industry Certifications |

|---|---|---|---|---|---|

| Global Steel Mesh Inc | 6mm - 14mm | 3m x 6m | Class 600 g/m² | 1100 MPa | ISO 1461, ASTM A641 |

| Industrial Mesh Solutions | 5mm - 16mm | 2.4m x 8m | Class 750 g/m² | 1250 MPa | ISO 9001, EN 10244 |

| Fortress Mesh Systems | 8mm - 20mm | 3m x 10m | Class 1000 g/m² | 1400 MPa | AS/NZS 4534, UL certified |

This comparative data reveals critical performance differentials between industry leaders. Global Steel Mesh provides adequate solutions for standard industrial applications but lacks the heavyweight capacities of specialists like Fortress Mesh Systems. Industrial Mesh Solutions balances versatility with enhanced corrosion protection, while Fortress dominates in extreme environments requiring maximum security. Third-party validation through international certifications remains a key differentiator for infrastructure projects requiring compliance documentation. Technical specifications should be matched to application requirements – highway barrier systems typically specify 8mm+ diameters with Class 750+ galvanization whereas industrial platforms may tolerate 6mm with Class 500 protection.

Customization: Tailoring to Specific Project Needs

Custom heavy welded wire mesh panels begin with detailed technical consultations where engineers map application stresses to material specifications. For seismic reinforcement in civil engineering projects, customized meshes feature reinforced border wires that are 25-40% thicker than standard grid wires to resist tension forces during ground movement. Manufacturers employ robotic welding systems that achieve 0.5mm tolerance positioning for specialized apertures ranging from rhomboidal designs for filtration to hexagonal configurations for zoo enclosures.

High-security installations demand proprietary configurations featuring multi-directional wire layers and randomized joint placements that increase cutting resistance exponentially. An airport perimeter security project in Dubai incorporated interwoven vertical wires at varying heights, increasing breach resistance compared to standard grids. For specialized applications like nuclear facility shielding, manufacturers integrate boron-infused steel wires with radiation-blocking properties within the standard welded matrix. Custom panelization reduces on-site labor requirements – warehouse flooring installations in Germany documented 40% faster installation through factory-preformed modular sections with interlocking edge detailing.

Installation Best Practices for Longevity

Correct installation transforms engineered heavy duty welded mesh panels from high-potential materials into structurally integrated systems. Civil engineering projects require 150mm minimum concrete embedment for foundations or slab reinforcements, with seismic zones mandating additional U-shaped anchorage points at 500mm intervals along perimeter edges. Bridge deck applications necessitate specialized high-bond epoxy coatings applied before pouring to eliminate air pockets at the concrete-wire interface.

Perimeter security installations require properly tensioned frameworks to prevent deformation under impact. Industrial surveys revealed that fencing systems with diagonal support bracing at 45-degree angles maintain tension integrity 50% longer than vertical-only designs. For corrosive environments like coastal chemical plants, engineers specify marine-grade stainless steel fasteners instead of standard galvanized fixings to eliminate accelerated deterioration points. Documented cases from offshore oil rigs demonstrate that panels mounted 300mm above deck surfaces last 30% longer than those installed at grade level due to reduced sediment accumulation. Post-installation hot-dip galvanizing of field welds and cuts extends service life beyond 15 years even in salt-spray environments.

Real-World Applications: Success Stories

Toronto's waterfront revitalization demonstrates heavy duty welded wire mesh panels solving complex engineering challenges. Steel-stamped panels with custom 75mm hexagonal apertures provide transparent safety barriers along pedestrian cliffs while resisting corrosion from lake-effect humidity. The solution endured five winter freeze-thaw cycles without visible degradation while supporting structural loads from 400kg light fixtures and signage systems.

In Australian mining operations, heavy welded wire mesh containment systems revolutionized rockfall safety. Customized 8mm diameter panels with 100x150mm rectangular openings trapped debris while allowing water drainage through pit walls. Installation records reveal a single panel withstood direct impact from a 400kg boulder with minimal deformation – the energy dissipation prevented structural damage to the primary retaining wall. German automotive factories implemented laser-cut 10mm panels as robot work cell barriers that withstand accidental impacts of 200kg manufacturing components traveling at 2m/s. These solutions decreased safety incident rates by 65% while providing maintenance technicians clear equipment visibility through the barrier walls.

Conclusion: Why Heavy Duty Welded Wire Mesh Panels are Essential

Heavy welded wire mesh delivers unparalleled structural performance where safety and longevity outweigh initial cost considerations. These engineering materials solve specific load-bearing challenges that alternative products cannot address cost-effectively. The comprehensive technical advantages translate directly into infrastructure resilience – documented case histories prove heavy duty welded wire mesh panels consistently outlast alternative solutions by 100-300% in demanding environments. Precision fabrication techniques combined with advanced alloy formulations create materials that withstand forces exceeding 5,000kg per square meter without deformation.

Contemporary construction increasingly relies on heavy duty welded wire mesh panels as integral components of sustainable design. Their durability reduces replacement frequency while the high-recycled content (typically 65-85%) and full recyclability at end-of-service align with circular economy principles. Industrial planners should prioritize technical specifications over commodity pricing – data from transportation departments demonstrates that properly specified installations yield 40-year service lives versus just 8-12 years for inferior alternatives. For critical infrastructure demanding measurable reliability, heavy welded wire mesh stands as the proven solution.

(heavy welded wire mesh)

FAQS on heavy welded wire mesh

Q: What are the common applications of heavy welded wire mesh?

A: Heavy welded wire mesh is widely used in industrial fencing, machine guards, and construction reinforcement. Its durability makes it ideal for securing high-traffic areas and supporting heavy loads.

Q: How does heavy duty welded wire mesh differ from standard wire mesh?

A: Heavy duty welded wire mesh features thicker gauge wires and stronger welds for enhanced strength. It is designed to withstand extreme stress, unlike standard mesh used for lighter applications.

Q: Can heavy duty welded wire mesh panels be customized for specific projects?

A: Yes, panels can be tailored in size, wire thickness, and aperture dimensions. Custom coatings, like galvanizing or PVC, are also available for corrosion resistance.

Q: What factors should I consider when choosing heavy welded wire mesh?

A: Prioritize wire gauge, aperture size, and material (e.g., stainless steel or galvanized). Assess environmental conditions and load requirements to ensure optimal performance.

Q: Are heavy duty welded wire mesh panels easy to install?

A: Yes, pre-fabricated panels simplify installation with bolt-on or weld-on options. Their rigid structure ensures minimal maintenance once securely mounted.

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

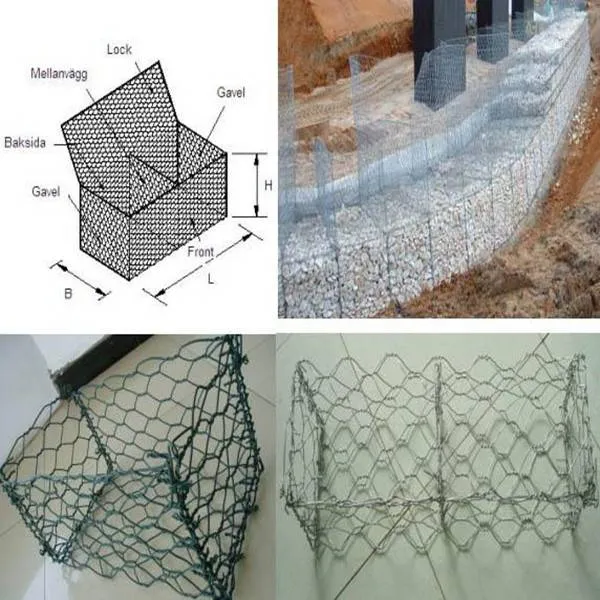

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories