aŭg . 18, 2025 04:00 Back to list

Durable PVC Hexagonal Wire Mesh Supplier | Factory Direct

Strategic Insights into PVC Hexagonal Wire Mesh for Industrial Applications

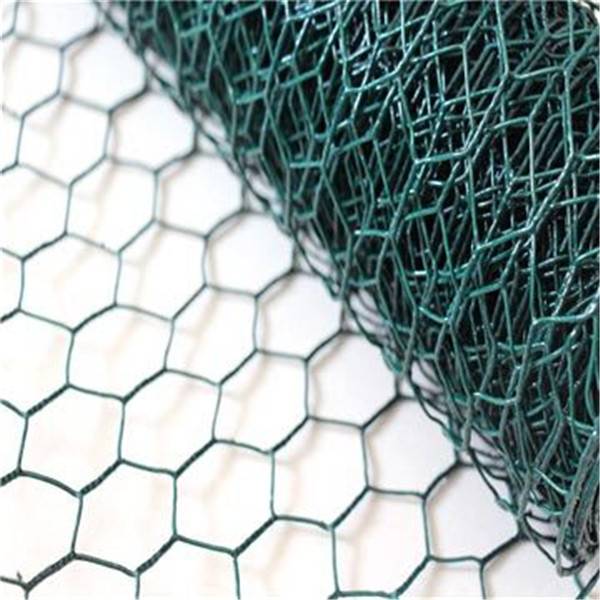

In the demanding landscape of modern infrastructure and agricultural development, the selection of appropriate materials is paramount for ensuring long-term durability and cost-efficiency. This holds particularly true for fencing, containment, and erosion control solutions, where resistance to environmental degradation is a critical factor. PVC Coated Galvanized Hexagonal Wire Netting, commonly known as pvc hexagonal wire mesh supplier, has emerged as a superior choice, offering a robust blend of strength, flexibility, and exceptional corrosion resistance. Its unique hexagonal weave provides a resilient structure capable of withstanding significant stress, making it ideal for a multitude of applications ranging from poultry enclosures to sophisticated gabion structures in civil engineering projects. The protective PVC layer not only enhances its lifespan by preventing rust and degradation but also provides an aesthetic appeal, making it suitable for both functional and visible installations. Understanding the intricate technical parameters and the comprehensive manufacturing process of this material is crucial for procurement specialists, project managers, and engineers aiming to optimize their material sourcing strategies and ensure the longevity of their investments. This detailed guide explores the nuances of PVC hexagonal wire mesh, offering an in-depth look at its production, applications, and the key considerations when partnering with a reputable factory.

The market for PVC hexagonal wire mesh is currently experiencing significant growth, driven by increasing global demand for sustainable and durable construction materials, coupled with expanding agricultural and aquaculture industries. Innovations in PVC coating technology have led to products with enhanced UV resistance and flexibility, further extending their applicability in diverse climatic conditions. As a leading pvc hexagonal wire mesh factory, we observe a clear trend towards specifications that emphasize both high tensile strength and superior adhesion of the PVC coating to the galvanized wire core, ensuring maximal protection against abrasion and chemical exposure. Furthermore, the rising awareness regarding environmental impact has led to a preference for materials with extended service lives, thereby reducing the frequency of replacement and associated waste. This strategic shift necessitates a deeper understanding of material science and production methodologies to identify suppliers capable of delivering products that not only meet current performance benchmarks but also anticipate future industry demands. Our commitment to rigorous quality control and continuous improvement ensures that our PVC hexagonal wire mesh products align with these evolving market requirements, providing unparalleled value and reliability for our global clientele across various sectors.

Understanding PVC Hexagonal Wire Mesh: Industry Trends & Technical Parameters

The evolution of the wire mesh industry has been marked by a relentless pursuit of materials that offer enhanced durability, cost-effectiveness, and environmental resilience. PVC Coated Galvanized Hexagonal Wire Netting stands at the forefront of this evolution, presenting a solution that significantly extends the lifespan of installations in corrosive environments. Industry trends indicate a growing preference for PVC-coated mesh over traditional galvanized options, primarily due to its superior resistance to acids, alkalis, and saline conditions, which are prevalent in agricultural settings and coastal areas. This trend is also fueled by an increasing emphasis on aesthetic integration in urban and agricultural landscapes, where the green or black PVC coating provides a more visually appealing and less intrusive solution compared to raw galvanized wire. Furthermore, the global drive towards sustainable practices favors products with longer service lives, reducing the ecological footprint associated with frequent material replacement. Technical advancements in polymer chemistry have led to PVC coatings that are more flexible, less prone to cracking, and highly resistant to UV degradation, ensuring the mesh maintains its structural integrity and protective qualities over decades of exposure. This continuous innovation makes a pvc hexagonal wire mesh supplier a pivotal partner in various critical applications, from securing vast farmlands to fortifying riverbanks against erosion, underlining its versatility and indispensable role in modern construction and environmental management.

For discerning buyers, understanding the technical specifications of PVC hexagonal wire mesh is paramount. Key parameters include the wire gauge (often expressed in BWG – Birmingham Wire Gauge), which dictates the wire's thickness and, consequently, the mesh's strength and rigidity. Common gauges range from 18 BWG (1.2mm) to 22 BWG (0.7mm) for lighter applications, with heavier gauges used for more demanding structural roles. Mesh size, defined by the distance between parallel wires in the hexagonal pattern (e.g., 1 inch, 2 inch), influences the size of objects it can contain and its overall flexibility. The quality of galvanization, typically hot-dip galvanization, provides the primary corrosion barrier, with the zinc coating weight being a crucial indicator of its effectiveness. Finally, the thickness and adhesion of the PVC coating are critical; a uniform, well-bonded PVC layer ensures optimal protection and resistance to peeling or cracking. Tensile strength, measured in MPa, indicates the material's resistance to breaking under tension, a vital characteristic for fencing and containment applications. Adherence to international standards such as ASTM A641 for galvanized wire and specific PVC coating thickness standards ensures product consistency and performance. A reputable pvc hexagonal wire mesh factory will provide detailed specifications on all these parameters, often accompanied by certified test reports, guaranteeing the product's suitability for specific project requirements and ensuring long-term reliability in diverse environmental conditions, thereby cementing trust with their clientele.

Common Technical Specifications for PVC Hexagonal Wire Mesh:

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Wire Gauge (BWG) | 18 BWG (1.2mm) to 22 BWG (0.7mm) | Determines strength, rigidity, and application suitability. Lower BWG means thicker wire. |

| Mesh Size | 1/2 inch, 1 inch, 2 inch, 3 inch | Affects containment capability, flexibility, and flow (for gabions). |

| Zinc Coating Weight | 30-200 g/m² (ASTM A641 standards) | Primary corrosion protection layer. Higher weight indicates better corrosion resistance. |

| PVC Coating Thickness | 0.2mm to 0.6mm (over galvanized wire) | Enhances corrosion resistance, UV protection, and aesthetic appeal. |

| Tensile Strength | 350-550 MPa | Indicates resistance to breaking under tension, crucial for structural integrity. |

| Roll Height | 0.5m to 2.0m | Standard roll dimensions for various applications and ease of installation. |

| Roll Length | 10m to 50m | Common lengths for practical handling and installation efficiency. |

The Manufacturing Journey: Process Flow of PVC Coated Galvanized Hexagonal Wire Netting

The production of high-quality PVC Coated Galvanized Hexagonal Wire Netting is a sophisticated multi-stage process that combines metallurgical precision with advanced polymer technology, ensuring the final product meets stringent performance and durability requirements. It commences with the selection of premium low-carbon steel wire rods, which undergo a meticulous drawing process to achieve the precise wire gauge required for the mesh. This initial step is critical as the uniformity and tensile strength of the raw wire directly influence the integrity of the finished product. Following wire drawing, the steel wire is subjected to hot-dip galvanization, a crucial process where the wire is immersed in a bath of molten zinc. This creates a metallurgically bonded zinc coating that acts as the primary sacrificial layer, offering unparalleled corrosion resistance against environmental factors. The thickness of this zinc coating is precisely controlled to meet international standards such as ISO 1461, ensuring maximum protection and extended lifespan for the mesh. A well-executed galvanization process is the backbone of the product's longevity, especially when the mesh is deployed in harsh or corrosive environments, making it a critical differentiator for any reputable pvc hexagonal wire mesh supplier. The meticulous execution of this stage directly impacts the product's resistance to rust and degradation, underpinning its suitability for long-term outdoor applications, from agricultural fencing to coastal erosion control.

After galvanization, the galvanized wire proceeds to the weaving stage, where specialized machinery meticulously twists and interlocks the wires to form the distinctive hexagonal mesh pattern. This weaving method, often referred to as reverse twist or double twist, ensures exceptional structural stability and prevents unraveling even if a section of the wire is cut. This inherent flexibility of the hexagonal weave makes it highly adaptable to uneven terrains and external forces, providing superior performance in containment and protective applications. The final and arguably most distinctive stage is the PVC coating application. The galvanized hexagonal wire mesh undergoes a specialized fluid bed or extrusion coating process where it is uniformly coated with a layer of high-quality polyvinyl chloride (PVC). This PVC layer not only provides a secondary, robust barrier against corrosion, UV radiation, and chemical exposure but also offers a smooth, aesthetically pleasing finish. The PVC material used is selected for its flexibility, non-toxicity, and resistance to cracking, ensuring the coating remains intact throughout the product's lifespan. Comprehensive quality control measures are integrated throughout the entire manufacturing process, from raw material inspection to final product testing. These include dimensional checks, adhesion tests for both galvanization and PVC coating, tensile strength tests, and salt spray tests, all performed in accordance with international standards like ISO 9001 and ASTM. These rigorous inspections ensure that every batch of pvc hexagonal wire mesh meets the specified technical parameters and quality benchmarks, guaranteeing consistent performance and reliability for diverse applications globally.

Applications and Technical Advantages of PVC Coated Hexagonal Mesh

The inherent design and material composition of PVC Coated Galvanized Hexagonal Wire Netting provide it with a distinct advantage across a wide spectrum of applications, making it a versatile choice for both agricultural and industrial sectors. In agriculture, it is widely utilized as pvc chicken mesh price fencing for poultry enclosures, protecting livestock from predators while offering excellent ventilation. Its flexibility allows for easy installation around varied terrains, making it suitable for garden fencing, vineyard protection, and even for crafting protective cages for delicate plants. Beyond agriculture, its robust nature finds critical roles in light-duty security fencing, particularly for residential and commercial properties where a blend of security and aesthetic appeal is desired. In environmental protection and civil engineering, this mesh is an essential component in gabion baskets and revet mattresses for erosion control along riverbanks, slopes, and coastal areas. The hexagonal weave, combined with the flexible PVC coating, allows the structures to conform to ground movement without fracturing, ensuring long-term stability in dynamic environments. Furthermore, it is employed in rockfall netting, preventing dislodged rocks from posing hazards along highways and railways, demonstrating its critical safety function. The adaptability and resilience of pvc hexagonal mesh underscore its indispensable role in modern protective and constructive applications globally.

Technically, the advantages of PVC Coated Galvanized Hexagonal Wire Netting are multifaceted and contribute significantly to its superior performance and cost-effectiveness over its lifespan. Foremost is its exceptional corrosion resistance, derived from the synergistic protection offered by both the hot-dip galvanized layer and the external PVC coating. This dual-layer defense renders it highly resistant to rust, chemical degradation, and the corrosive effects of salt water, extending its service life significantly compared to plain galvanized mesh, especially in humid or marine environments. The PVC coating also imparts superior UV resistance, preventing material degradation and color fading even under prolonged exposure to sunlight, ensuring the mesh retains its structural integrity and aesthetic quality for decades. Moreover, the smooth, non-abrasive surface of the PVC coating makes it safer for livestock and personnel, reducing the risk of injuries. Its inherent flexibility and ease of cutting and shaping simplify installation processes, significantly reducing labor costs and project timelines. While the initial chicken wire plastic price might be slightly higher than untreated or solely galvanized alternatives, the extended lifespan, minimal maintenance requirements, and superior performance of pvc chicken mesh price translate into a lower total cost of ownership over time. This makes it an economically sound investment for long-term projects, providing both durability and aesthetic value in a single, high-performing solution that mitigates the need for frequent replacements.

Choosing Your Supplier: Factors and Comparisons

Selecting the right pvc hexagonal wire mesh supplier is a strategic decision that directly impacts project success, product longevity, and overall return on investment. It extends beyond merely comparing initial costs; it involves a comprehensive evaluation of the supplier's expertise, quality control protocols, customization capabilities, and post-sales support. A reputable supplier should demonstrate a profound understanding of material science, manufacturing precision, and industry-specific applications, evidenced by their ability to provide detailed technical specifications, relevant certifications (such as ISO 9001 for quality management and ASTM standards for product performance), and transparent supply chain practices. Companies with a long-standing presence in the industry often possess invaluable experience in anticipating customer needs and solving complex application challenges, translating into superior product offerings and reliable delivery. Furthermore, a strong pvc hexagonal wire mesh factory will invest heavily in research and development, ensuring their products incorporate the latest advancements in corrosion resistance, UV stability, and material strength. Evaluating their track record through client testimonials, case studies, and industry reputation provides critical insights into their reliability and commitment to customer satisfaction. Opting for a supplier who prioritizes these aspects ensures that the purchased mesh not only meets immediate project requirements but also offers sustained performance and durability, avoiding costly replacements and maintenance in the future.

When evaluating potential suppliers for pvc hexagonal wire mesh, a comparative analysis of their offerings and service models is highly beneficial. Beyond product specifications, consider their manufacturing capacity, lead times for large orders, and flexibility in accommodating custom dimensions or colors. Some suppliers might offer competitive pricing but compromise on raw material quality or coating thickness, leading to premature product failure. Conversely, premium suppliers might have higher upfront costs but deliver products with extended warranties and superior performance, offering a lower total cost of ownership over the product's lifespan. Proximity to your operational base and logistics capabilities are also important, as efficient shipping can significantly reduce project timelines and transportation costs. Look for suppliers who offer comprehensive technical support, including installation guidelines, material handling advice, and responsive customer service for any queries or issues that may arise post-purchase. Their commitment to sustainability, evidenced by eco-friendly manufacturing processes or recyclable product components, can also be a significant factor for environmentally conscious projects. Ultimately, the choice of a pvc hexagonal wire mesh supplier should be a partnership built on trust, demonstrated expertise, and a shared commitment to quality and project success. Below is a comparative table highlighting key supplier evaluation criteria.

Supplier Evaluation Criteria & Comparison:

| Criterion | High-Value Supplier (Example) | Standard Supplier (Example) |

|---|---|---|

| Quality Certifications | ISO 9001, ASTM, SGS Certified | Basic internal quality checks |

| Product Customization | Extensive (mesh size, wire gauge, color, roll dimensions) | Limited standard options only |

| Warranty & Support | 10+ years warranty, dedicated technical support | Standard 1-year warranty, basic customer service |

| Lead Time (Large Orders) | Typically 2-4 weeks (efficient production) | 4-8 weeks or longer (less optimized) |

| Material Traceability | Full raw material traceability and test reports | Limited or no traceability |

Custom Solutions and Real-World Applications of PVC Hexagonal Wire Mesh

The adaptability of PVC Coated Galvanized Hexagonal Wire Netting extends far beyond its standard applications, making it an ideal candidate for tailored solutions designed to meet highly specific project requirements. Leading manufacturers and pvc hexagonal wire mesh factory operations understand that off-the-shelf products may not always suffice for complex engineering challenges or unique environmental conditions. Therefore, they offer extensive customization options, including variations in wire gauge to achieve specific tensile strength and flexibility, diverse mesh sizes to control containment or flow, and even bespoke PVC colors to seamlessly integrate with a project's aesthetic or branding guidelines. For instance, a client requiring robust protection against larger pests in a remote agricultural setting might specify a heavier wire gauge and smaller mesh opening, while a vineyard requiring bird exclusion might opt for a lighter gauge with a very fine mesh, coupled with a dark green PVC coating to blend invisibly with the foliage. Such custom solutions ensure optimal performance, minimize material waste, and streamline installation processes, ultimately leading to significant cost savings and enhanced project efficiency. The ability to innovate and adapt product specifications makes a reliable pvc hexagonal wire mesh supplier an invaluable partner for engineers and project developers facing unique challenges, moving beyond standard product delivery to offering comprehensive material solutions.

Real-world applications vividly demonstrate the versatility and effectiveness of customized pvc hexagonal wire mesh. Consider a large-scale erosion control project along a riverbed where variable flow rates and soil compositions necessitate gabion structures of differing densities and strengths. A customized hexagonal wire mesh, with specific wire gauges and coating thicknesses, can be engineered to precisely meet these hydrological and geological demands, ensuring long-term stability and environmental protection. Another compelling example comes from the aquaculture industry, where specialized mesh cages are required for fish farming. Here, the mesh must be highly resistant to saltwater corrosion and marine biofouling, while also being non-toxic to aquatic life. Custom-formulated PVC coatings, coupled with precise mesh openings to optimize water flow and prevent escape, can be developed. Furthermore, in urban landscaping, PVC hexagonal mesh can be custom-fabricated into decorative trellises or protective barriers around sensitive public areas, offering both functionality and aesthetic appeal. These bespoke applications underscore the importance of collaborating with a flexible and knowledgeable pvc hexagonal wire mesh supplier who can translate complex project specifications into tangible, high-performance products. This collaborative approach fosters innovation and ensures that the final product is not just a commodity but a precisely engineered component tailored for maximum impact and longevity, reaffirming the material's critical role across diverse industrial and environmental contexts.

Ensuring Reliability: Quality Assurance & Support from Your PVC Hexagonal Wire Mesh Supplier

The cornerstone of a trustworthy pvc hexagonal wire mesh supplier lies in their unwavering commitment to quality assurance and comprehensive customer support. For B2B decision-makers, assurance of product reliability translates directly into project success and risk mitigation. A reputable factory adheres to stringent quality management systems, often evidenced by certifications such as ISO 9001:2015, which signifies a consistent commitment to meeting customer and regulatory requirements. This commitment extends from the meticulous sourcing of raw materials—ensuring high-grade steel wire and UV-stabilized PVC compounds—to rigorous in-process inspections at every manufacturing stage. Key quality checks include verifying wire gauge accuracy, confirming uniform zinc coating weight and adhesion, and precisely measuring PVC coating thickness and bond strength. Furthermore, advanced laboratories conduct performance tests such as salt spray tests (ASTM B117) to evaluate corrosion resistance, UV exposure tests to simulate long-term outdoor conditions, and tensile strength tests to confirm mechanical integrity. These systematic quality control measures, backed by verifiable test reports and data sheets, provide clients with the confidence that the PVC hexagonal wire mesh they procure will perform as expected, even under the most challenging environmental conditions, thereby safeguarding their investments and reputation.

Beyond product quality, the efficacy of a pvc hexagonal wire mesh supplier is also judged by their logistical efficiency and responsive after-sales support. For large-scale industrial or agricultural projects, timely delivery is crucial to maintaining project schedules and avoiding costly delays. Reliable suppliers provide clear, transparent delivery timelines and leverage established logistics networks to ensure efficient and safe transportation of bulk orders worldwide. Furthermore, a comprehensive warranty program, typically extending for several years (e.g., 10-15 years against manufacturing defects and premature corrosion), underscores the manufacturer's confidence in their product's durability. This warranty provides an essential layer of protection for the buyer, offering recourse in the unlikely event of product failure. Exceptional customer support involves more than just addressing complaints; it encompasses providing technical assistance, offering expert advice on installation best practices, and developing long-term partnerships with clients. This includes being available for queries regarding product specifications, application suitability, or custom orders, thereby ensuring that clients receive not just a product, but a complete solution supported by industry experts. This holistic approach to quality and service distinguishes a premier pvc hexagonal wire mesh factory and builds enduring trust with its global clientele.

Frequently Asked Questions (FAQ) about PVC Hexagonal Wire Mesh

PVC hexagonal wire mesh offers significantly enhanced durability and corrosion resistance compared to standard galvanized mesh due to its dual-layer protection. The core is hot-dip galvanized steel, providing primary defense against rust. Over this, a robust PVC (Polyvinyl Chloride) coating is applied, acting as a secondary barrier against harsh environmental elements such as moisture, chemicals, salt spray, and UV radiation. This combination drastically extends the product's lifespan, reduces maintenance requirements, and ensures long-term aesthetic integrity, making it ideal for outdoor applications in demanding conditions. Its superior resistance to various forms of degradation translates to a lower total cost of ownership over its extended service life, making it a more economical choice for long-term projects despite a slightly higher initial chicken wire plastic price.

The lifespan of PVC hexagonal wire mesh can vary depending on environmental conditions, installation quality, and the specific product specifications (e.g., thickness of galvanization and PVC coating). However, under normal conditions and with proper installation, high-quality PVC Coated Galvanized Hexagonal Wire Netting is designed to last anywhere from 10 to 20 years, and often even longer. The PVC coating is specifically formulated to resist UV degradation and cracking, ensuring the protective layer remains intact for an extended period. Many reputable pvc hexagonal wire mesh supplier provide warranties ranging from 10 to 15 years, reflecting the expected longevity and performance of their products, offering peace of mind to project managers and end-users.

Absolutely. A key advantage of working with an experienced pvc hexagonal wire mesh factory is the availability of extensive customization options. This includes varying the wire gauge (thickness) to achieve desired strength, adjusting mesh size to meet containment requirements, and even specifying custom PVC colors to match aesthetic preferences or branding. Roll heights and lengths can also be tailored to optimize installation efficiency for large-scale projects, minimizing waste and reducing labor costs. This flexibility ensures that the mesh can be precisely adapted to unique industrial, agricultural, or environmental applications, providing a bespoke solution that maximizes efficiency and performance for diverse project specifications and complex engineering challenges.

When sourcing PVC hexagonal wire mesh, it is crucial to look for suppliers who adhere to international quality standards. Key certifications and standards include ISO 9001 (for quality management systems), ASTM International standards (e.g., ASTM A641 for galvanized steel wire, which specifies zinc coating weight and quality), and potentially other regional or industry-specific certifications. These standards ensure consistency in material quality, manufacturing processes, and product performance. A transparent pvc hexagonal wire mesh supplier will readily provide test reports, material safety data sheets, and certification documents upon request, demonstrating their commitment to quality and product compliance, which is essential for B2B procurement and project reliability.

Conclusion: The Strategic Advantage of Partnering with a Premier PVC Hexagonal Wire Mesh Supplier

The selection of PVC Coated Galvanized Hexagonal Wire Netting for industrial, agricultural, and civil engineering projects represents a strategic investment in durability, cost-efficiency, and environmental resilience. As this comprehensive guide has elucidated, the superiority of this material stems from its meticulously engineered manufacturing process, which combines robust galvanization with a protective, aesthetic PVC coating. This dual-layer defense system provides unparalleled resistance to corrosion, UV degradation, and physical wear, significantly extending its service life beyond conventional wire mesh products. Its versatility, demonstrated through diverse applications from livestock containment to critical erosion control, makes it an indispensable component in modern infrastructure development. Moreover, the ability to customize technical specifications, including wire gauge, mesh size, and color, allows for tailored solutions that precisely meet the nuanced demands of complex projects, optimizing performance and reducing long-term operational costs.

Ultimately, the true value derived from utilizing PVC hexagonal wire mesh is inextricably linked to the expertise and reliability of its source. Partnering with a premier pvc hexagonal wire mesh supplier is not merely a transactional decision but a strategic collaboration. Such a supplier distinguishes itself through rigorous adherence to international quality standards, transparent production processes, comprehensive technical support, and a steadfast commitment to customer satisfaction. Their deep industry knowledge, capacity for innovation, and ability to provide verifiable product data and certifications ensure that clients receive a product that is not only high-performing but also consistently reliable over its extended lifespan. By prioritizing these critical factors, B2B decision-makers can secure a material solution that contributes significantly to project longevity, sustainability, and ultimately, a superior return on investment, cementing the pivotal role of a trusted pvc hexagonal wire mesh factory in the global supply chain.

References

- ASTM International. (n.d.). Standard Specification for Zinc-Coated (Galvanized) Carbon Steel Wire, ASTM A641/A641M.

- International Organization for Standardization. (n.d.). Quality management systems – Requirements, ISO 9001:2015.

- NACE International (AMPP). (n.d.). Corrosion Basics.

- The Galvanizers Association. (n.d.). The Corrosion Protection of Steel.

- Plastics Industry Association. (n.d.). PVC Material Properties.

-

build-a-discreet-chicken-run-with-sturdy-green-coated-chicken-wire

NewsAug.23,2025

-

a-guide-to-selecting-the-most-durable-field-gates-for-your-property

NewsAug.23,2025

-

green-mesh-fencing-rolls-offer-versatile-solutions-for-diverse-needs

NewsAug.23,2025

-

chain-fence-for-durable-and-versatile-enclosure-solutions

NewsAug.23,2025

-

garden-edging-fence-for-functional-and-decorative-landscaping

NewsAug.23,2025

-

3d-wire-mesh-fence-for-versatile-security-and-decoration

NewsAug.23,2025

Products categories