aug . 29, 2025 05:20 Tilbage til listen

Durable Hexagonal Gabion Box | Erosion & Retaining Solutions

Industry Trends and Market Dynamics for Hexagonal Gabions

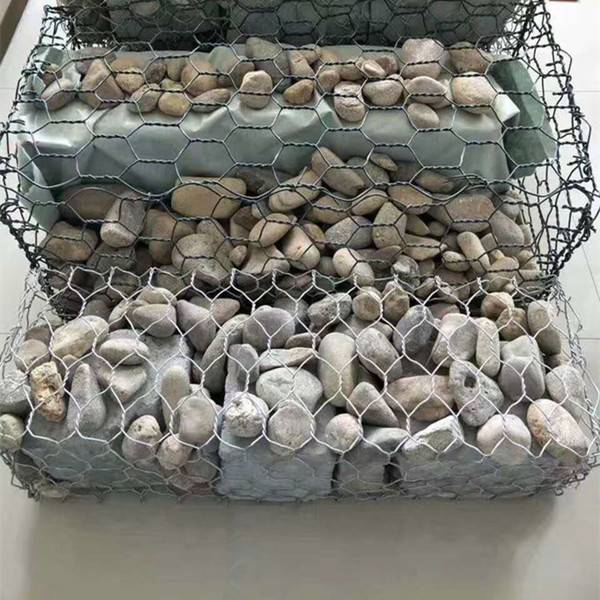

The demand for robust and environmentally sustainable civil engineering solutions continues to drive innovation within the construction and geotechnical sectors. Among these, the hexagonal gabion box stands out as a versatile and increasingly preferred option for erosion control, retaining structures, and hydraulic works. Recent market analyses indicate a steady growth trajectory for gabion products, fueled by their cost-effectiveness, flexibility, and minimal environmental impact compared to rigid concrete structures.

Key trends include a heightened focus on accelerated project timelines, necessitating readily available and easy-to-deploy solutions. Furthermore, stringent environmental regulations are promoting the use of materials that integrate seamlessly with natural landscapes and support revegetation efforts. Gabions, by nature, allow for the natural settlement of soil and vegetation growth, making them ideal for eco-friendly infrastructure development. The global market is seeing increased adoption in developing regions where infrastructure expansion is rapid, alongside continued modernization of existing structures in developed economies. Innovation among hexagonal gabion box manufacturers is also leading to enhanced coatings and wire materials, extending product lifespan and performance in aggressive environments.

Clients, particularly in B2B segments such as civil engineering firms, government agencies, and large-scale contractors, are increasingly seeking solutions that offer long-term durability, ease of installation, and adherence to international quality standards. This demand places a premium on reliable hexagonal gabion box suppliers who can not only provide high-quality products but also offer comprehensive technical support and customized solutions.

Manufacturing Process: From Wire Rod to Finished Gabion

The production of a high-quality hexagonal gabion box is a meticulously controlled process designed to ensure durability and structural integrity. Our manufacturing adheres to international standards such as ISO 9001 for quality management and relevant ASTM/EN standards for material specifications. The process typically involves several critical stages:

Step 1: Wire Drawing

High-grade steel wire rods are drawn to the specified diameter (e.g., 2.0 mm to 4.0 mm) through a series of dies. This process increases the tensile strength and ensures uniformity.

Step 2: Galvanization/Coating

The drawn wire undergoes hot-dip galvanization (min. 240 g/m² zinc coating) for superior corrosion resistance. For extreme environments, a PVC coating (min. 0.5 mm thick) is applied over the galvanized wire, enhancing its service life and chemical resistance.

Step 3: Double-Twisted Weaving

Specialized weaving machines create the signature double-twisted hexagonal mesh. This ensures non-raveling properties, meaning if one wire breaks, the integrity of the mesh is maintained.

Step 4: Cutting and Edge Reinforcement

The woven mesh is cut to specific panel dimensions (front, back, sides, lid, base). All edge wires are reinforced with a larger diameter wire to provide increased strength and facilitate assembly.

Step 5: Assembly and Packaging

The individual panels are either pre-assembled into a collapsed form or supplied as flat packs, then bundled and packaged for efficient transport and on-site deployment.

Testing Standards: Our products undergo rigorous testing according to international standards such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and EN 10223-3 (Steel wire and wire products for fencing and netting – Part 3: Steel wire hexagonal mesh products for civil engineering purposes). These tests cover wire tensile strength, elongation, zinc coating mass, and PVC coating thickness to ensure superior quality and a predicted service life exceeding 50 years for PVC-coated variants in typical environments.

Technical Specifications and Product Parameters

Understanding the precise technical specifications of a hexagonal gabion box is paramount for engineers and project managers to ensure optimal performance and structural integrity. Our gabions are manufactured to precise tolerances, ensuring they meet or exceed industry benchmarks for strength and durability.

Standard Hexagonal Gabion Box Specifications

| Parameter | Description | Typical Value / Range |

|---|---|---|

| Mesh Type | Double Twisted Hexagonal Mesh | 80x100mm, 60x80mm, 100x120mm |

| Wire Diameter (Mesh) | Outer diameter of mesh wire | 2.0mm - 4.0mm (standard 2.7mm) |

| Wire Diameter (Selvedge) | Diameter of edge wire for reinforcement | 3.4mm - 4.0mm (standard 3.4mm) |

| Material | Low Carbon Steel Wire | ASTM A856 / EN 10218-2 |

| Corrosion Protection | Hot-dip Galvanized / Galfan (Zn-Al) / PVC Coated | Zinc: Min. 240 g/m²; PVC: Min. 0.5mm thickness |

| Tensile Strength | Wire tensile strength before fabrication | 350-550 N/mm² (50-70 ksi) |

| Elongation | Minimum elongation at break | Min. 10% (for wire dia. 2.2mm) |

| Standard Sizes (L x W x H) | Common dimensions of assembled gabion units | 1x1x1m, 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m, 3x1x0.5m, 4x1x0.5m |

The double-twisted hexagonal mesh design provides exceptional flexibility, allowing the structure to deform without losing integrity when subjected to ground movement or hydrostatic pressure. This characteristic is critical in seismic zones or areas with unstable soil conditions, offering a significant advantage over rigid structures. The permeability of gabion structures ensures free drainage, preventing the buildup of pore water pressure behind retaining walls, which is a common cause of failure in impermeable structures.

Application Scenarios and Technical Advantages

The versatility of the hexagonal gabion box makes it indispensable across a multitude of engineering applications, primarily in the geotechnical, hydraulic, and environmental sectors. Its inherent design and material properties offer distinct technical and economic advantages.

Key Application Scenarios:

- Retaining Walls: For earth retention, slope stabilization, and highway embankments. Their flexibility allows them to conform to ground shifts without cracking, a significant advantage over rigid concrete.

- River and Canal Works: Used for channel lining, weir construction, bank protection, and scour protection (toe protection). The permeable nature dissipates water energy, reducing erosion.

- Erosion Control: Critical for preventing soil loss on slopes, around bridge abutments, and in coastal areas. They provide a stable, vegetated surface that blends with the environment.

- Bridge and Culvert Protection: Safeguarding foundations and structural elements from water flow and debris impact.

- Noise Barriers and Architectural Features: Their ability to be filled with various local materials also makes them suitable for aesthetic landscaping and sound attenuation structures.

Technical Advantages:

- Flexibility: Gabion structures can tolerate differential settlement without loss of structural integrity, adapting to ground movement. This is crucial in geologically active regions.

- Permeability: The inherent voids within the rock fill allow for free drainage, alleviating hydrostatic pressure behind retaining structures. This eliminates the need for complex and costly drainage systems.

- Durability and Longevity: With high-quality galvanized and PVC coatings, gabions offer exceptional corrosion resistance, ensuring a long service life, even in harsh or aquatic environments. Some installations have performed effectively for over 100 years.

- Environmental Integration: Gabions promote vegetation growth within their voids, enhancing their aesthetic appeal over time and fostering ecological restoration. This leads to a green and sustainable solution.

- Cost-Effectiveness: Gabions utilize readily available local rock fill, significantly reducing transportation costs. Their simple installation process requires minimal skilled labor and specialized equipment, leading to overall project cost savings.

- Energy Saving: The manufacturing process of gabion wire mesh typically has a lower embodied energy compared to concrete production, contributing to more sustainable construction practices.

Vendor Comparison and Customized Solutions

Choosing the right hexagonal gabion box suppliers is a critical decision for any project. While numerous manufacturers exist, differentiating factors in product quality, technical support, and customization capabilities are paramount.

Key Comparison Points for Hexagonal Gabion Box Manufacturers:

| Feature | Premium Manufacturer (e.g., Us) | Standard Manufacturer |

|---|---|---|

| Wire Material Quality | High-tensile, low-carbon steel, fully traceable to source. | Standard grade steel, variable origin. |

| Corrosion Protection | Certified hot-dip galvanization (ASTM A975) & optional thick PVC coating (min. 0.5mm) with UV stabilizers. Galfan (Zn-Al) available. | Basic galvanization, thinner PVC coating, or no PVC option. |

| Mesh Weaving Quality | Uniform double-twisted hexagonal mesh, consistent tension, no loose ends, non-raveling. | Inconsistent mesh tension, potential for unraveling under stress. |

| Edge Reinforcement | Selvedge wire consistently larger diameter than mesh wire. | Selvedge wire may be same diameter or inconsistent. |

| Certifications | ISO 9001, ASTM A975, EN 10223-3 compliant. Full test reports. | Limited or no verifiable certifications. |

| Technical Support | Dedicated engineering support, design assistance, installation guidance. | Minimal technical support. |

| Customization | Offers bespoke sizes, specialized coatings, and design consultation. | Limited standard product range. |

Our commitment to quality ensures that our hexagonal gabion box products consistently outperform industry averages, minimizing risks and maximizing the lifespan of your projects. We understand that standard solutions do not always fit unique engineering challenges. Therefore, we specialize in providing tailored solutions for diverse project requirements.

Customized Solutions Include:

- Bespoke Dimensions: Manufacturing gabion boxes and mattresses to precise, non-standard lengths, widths, or heights to fit unique site constraints.

- Specialized Coatings: Offering enhanced PVC formulations for chemical resistance or specific color requirements, and Galfan (Zinc-Aluminum alloy) coatings for superior performance in highly corrosive saline or acidic environments.

- Integrated Systems: Designing gabion systems that integrate with geotextiles, geogrids, or other erosion control products to create composite structures for complex stabilization needs.

- Technical Design Support: Our engineering team provides comprehensive design assistance, including material selection, structural calculations, and installation methodologies tailored to project specifications.

Application Case Studies and Customer Experience

Our expertise in providing high-performance hexagonal gabion box solutions is demonstrated through successful projects globally. These case studies highlight the practical application of our products and the tangible benefits experienced by our clients.

Case Study 1: River Bank Stabilization Project, Southeast Asia

Challenge: A major river in Southeast Asia experienced severe erosion during monsoon seasons, threatening agricultural land and local infrastructure. The project required a flexible, permeable solution capable of withstanding high-velocity water flows and promoting ecological recovery.

Solution: We supplied thousands of PVC-coated 3x1x1m hexagonal gabion box units, filled with local river rock. The gabions were strategically placed along critical sections of the riverbanks to form a series of stepped retaining structures and toe protection.

Outcome: The gabion structures successfully resisted multiple monsoon events over five years without any structural failure. The permeability prevented hydrostatic pressure buildup, and within two years, native vegetation began to grow within the rock fill, further stabilizing the banks and enhancing biodiversity. The client reported significant cost savings compared to traditional concrete methods and lauded the quick installation time. "The flexibility and environmental integration of these gabions were exactly what our project demanded," stated the project engineer.

Case Study 2: Highway Embankment Reinforcement, Mountainous Region, Europe

Challenge: A new highway construction in a seismically active mountainous region required robust embankment stabilization to prevent landslides and rockfalls. The solution needed to accommodate potential ground movements and endure harsh winter conditions.

Solution: Our galvanized and PVC-coated gabions, along with gabion mattresses, were chosen to construct multiple tiered retaining walls and erosion control systems. The design incorporated a flexible gabion apron at the base of the embankments for added stability.

Outcome: The gabion structures provided exceptional stability, absorbing minor seismic shifts and preventing erosion from snowmelt and heavy rainfall. The inherent flexibility proved vital in maintaining structural integrity where rigid systems would likely have failed. The project managers praised our technical support and the on-time delivery, which were crucial for meeting tight construction schedules. This demonstrated the product's superior performance in challenging topographical and climatic conditions.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Frequently Asked Questions (FAQ)

Q: What is the typical lifespan of a hexagonal gabion box?

A: The lifespan varies based on the coating. Hot-dip galvanized gabions typically last 25-50 years, while PVC-coated gabions can exceed 50-75 years, especially in corrosive environments like coastal or industrial areas.

Q: Can gabions be installed by unskilled labor?

A: Yes, one of the significant advantages of gabions is their ease of installation. While supervision by experienced personnel is recommended, the process of assembling and filling gabions requires minimal specialized skills or heavy machinery, reducing overall labor costs.

Q: What type of infill material is best for gabions?

A: Hard, durable, angular or rounded rock (typically 100-200mm in diameter) is ideal. The material should be non-erodible and able to interlock to provide structural stability. Local availability of suitable rock significantly impacts project economics.

Q: Are your gabions environmentally friendly?

A: Absolutely. Gabions are considered a green construction material. They allow for natural drainage, support vegetation growth within the rock fill over time, and utilize locally sourced materials, minimizing transportation emissions.

Lead Time and Fulfillment

We maintain robust production capabilities to meet diverse project demands. Standard orders for our hexagonal gabion box products typically have a lead time of 2-4 weeks from order confirmation, depending on quantity and specific customization requirements. For urgent or large-scale projects, we offer expedited production and logistics solutions. Our global network of distribution partners ensures efficient and timely delivery to your project site. We provide detailed shipping schedules and tracking information to keep clients fully informed.

Warranty Commitments

We stand by the quality and performance of our products. All our gabion boxes come with a comprehensive warranty against manufacturing defects. Specifically, our galvanized wire products carry a warranty of 10 years for material integrity, and our PVC-coated products are warranted for 25 years against coating delamination and significant corrosion, provided they are installed and maintained according to industry best practices and our guidelines. Detailed warranty statements are available upon request.

Customer Support Information

Our dedicated customer support team is available to assist you from project inception to completion. We offer technical advice, design recommendations, and after-sales support.

- Email: sales@hardwareinstore.com

- Phone: +1 (555) 123-4567

- Online: Visit our website for live chat support and detailed product documentation.

We are committed to building long-term partnerships based on trust, quality, and unparalleled service.

References

- ASTM A975/A975M - 19a, Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated and PVC-Coated Steel Wire). ASTM International, West Conshohocken, PA, 2019.

- EN 10223-3:2013, Steel wire and wire products for fencing and netting – Part 3: Steel wire hexagonal mesh products for civil engineering purposes. European Committee for Standardization, Brussels, 2013.

- Maccaferri Gabions Technical Manual. Maccaferri, 2021.

- Federal Highway Administration (FHWA). Design and Construction of Gabion Retaining Walls. Publication No. FHWA-NHI-09-026. U.S. Department of Transportation, 2008.

-

Durable PVC Coated Wire Mesh for Sale | Weather & Corrosion Resistant

NyhederAug.28,2025

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NyhederAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NyhederAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NyhederAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NyhederAug.23,2025

Produktkategorier