aug . 27, 2025 05:20 Back to list

Durable Galvanized Welded Wire Mesh Panels for Security & Fencing

Introduction to Galvanized Welded Wire Mesh Panels

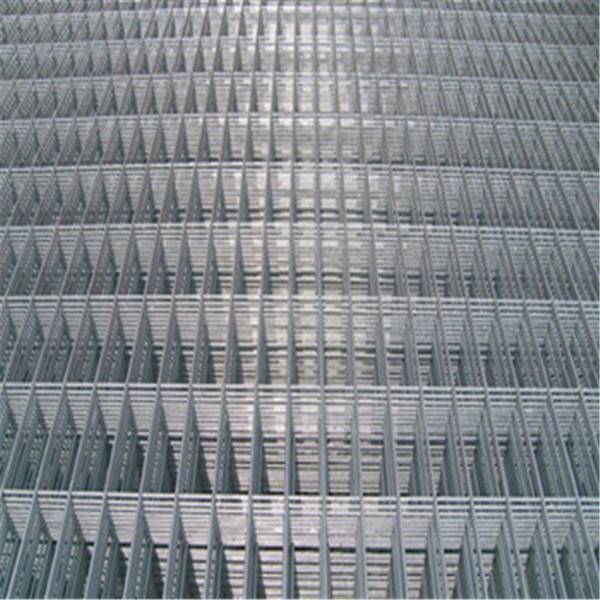

In the demanding landscape of industrial and construction applications, the integrity and durability of materials are paramount. Among the most versatile and robust solutions is the galvanized welded wire mesh panel. Engineered for exceptional strength and long-term corrosion resistance, these panels are formed by welding precisely aligned steel wires, which are then hot-dip galvanized or electro-galvanized to create a protective zinc coating. This process significantly enhances the material's resilience against environmental degradation, making it indispensable across a spectrum of B2B applications, from security fencing and machine guarding to animal enclosures and concrete reinforcement. Our focus in this comprehensive guide is to delve into the technical intricacies, application diversity, and strategic advantages that position galvanized welded wire mesh panels as a superior choice for discerning engineers and procurement professionals.

Manufacturing Process: From Raw Material to Finished Product

The production of galvanized welded wire mesh panel involves a meticulously controlled, multi-stage process designed to ensure structural integrity and superior protective coating.

Process Flow Schematic:

- Wire Drawing: High-carbon or low-carbon steel rods are drawn through a series of dies to achieve the desired wire gauge, ensuring consistent diameter and tensile strength.

- Straightening and Cutting: The drawn wires are precisely straightened and cut to specific lengths for the transverse and longitudinal wires of the mesh panel.

- Welding: Utilizing advanced automated welding machines, longitudinal and transverse wires are resistance welded at their intersections. This process, often employing precision CNC machinery, ensures strong, uniform welds without material degradation, forming a robust mesh matrix. The mesh opening, such as a 2x2 galvanized welded wire mesh panel or 4x4 galvanized wire mesh, is precisely controlled at this stage.

- Surface Preparation: The welded panels undergo thorough cleaning, degreasing, and pickling to remove impurities and oxides, preparing the surface for optimal zinc adhesion.

- Galvanizing:

- Hot-dip Galvanizing: Panels are immersed in a molten zinc bath (typically at 450-460°C). This creates a metallurgical bond between the steel and zinc, forming multiple layers of zinc-iron alloy and an outer layer of pure zinc. This method provides superior corrosion resistance, often exceeding 20-30 years in typical atmospheric conditions.

- Electro-galvanizing: (Less common for panels due to thinner coating) Zinc ions are deposited onto the steel surface via electrolysis, creating a thinner, but uniform, zinc layer. This method offers a cleaner finish but with less robust corrosion protection compared to hot-dip galvanizing.

- Quality Control & Testing: Each batch undergoes rigorous testing to comply with international standards such as ISO 9001 for quality management, ASTM A1064/A1064M for steel wire, and ASTM A123/A123M or ISO 1461 for hot-dip galvanizing. Tests include zinc coating thickness, adhesion, uniformity, and weld shear strength.

- Packaging: Finished panels are stacked and secured for safe transport, typically in bundles.

The materials primarily used are low carbon steel wires (ASTM A82/A185 compliant) or higher tensile steel wires, chosen for their excellent weldability and ductility. This precise manufacturing sequence ensures that each galvanized welded wire mesh panel offers optimal structural performance and extended service life, particularly in challenging environments.

Technical Specifications and Material Science

Understanding the technical specifications of galvanized welded wire mesh panel is crucial for precise application matching and optimal performance. Key parameters include wire gauge, mesh opening size, panel dimensions, and zinc coating thickness.

Common Product Specifications Table:

| Specification | Common Range | Details / Standards |

|---|---|---|

| Wire Diameter | 1.0 mm - 6.0 mm (19 SWG - 3 SWG) | Typical wire for 1 8 galvanized wire mesh is ~3.18mm. Wider range available for varied strength requirements. |

| Mesh Opening | 1/2" x 1/2" to 6" x 6" | Examples: 2x2 galvanized wire mesh, 4x4 galvanized wire mesh, 6x6 galvanized wire mesh. Critical for filtration, security, and animal containment. |

| Panel Width | 0.5 m - 2.5 m ( ~20 inches - ~98 inches) | Custom widths available to minimize waste in large projects. |

| Panel Length | 1.0 m - 6.0 m ( ~39 inches - ~236 inches) | Length adapted to specific installation requirements. |

| Zinc Coating Thickness | 40-600 g/m² (Hot-dip) / 10-30 g/m² (Electro) | Governed by ISO 1461 or ASTM A123/A123M, directly impacting corrosion resistance and service life. |

| Tensile Strength | 450-700 MPa | As per ASTM A82/A185 for cold-drawn steel wire. |

The metallurgical bond created during hot-dip galvanizing is critical. It creates a series of zinc-iron alloy layers (gamma, delta, zeta) before the outer pure zinc layer (eta). This multi-layered structure is significantly more durable and abrasion-resistant than electroplated coatings, which typically consist only of the eta layer. This intrinsic material advantage contributes directly to the extended service life and reduced maintenance costs of hot-dip galvanized welded wire mesh panel products.

Industry Trends and Key Innovations

The demand for robust, sustainable, and cost-effective materials continues to drive innovation in the wire mesh industry. Current trends for galvanized welded wire mesh panel include:

- Advanced Corrosion Protection: Beyond standard galvanization, research is focusing on duplex coatings (galvanizing plus powder coating) to offer enhanced aesthetic appeal and superior corrosion protection in highly aggressive environments, extending service life significantly.

- Sustainable Manufacturing: Manufacturers are increasingly adopting greener production processes, reducing energy consumption and waste, and utilizing recycled steel content to meet stringent environmental regulations and corporate social responsibility goals.

- Automation and Customization: The integration of AI and advanced robotics in welding and cutting processes allows for greater precision, higher production speeds, and the capability to produce highly customized panels with complex geometries and varied mesh patterns (e.g., specific 2x2 galvanized wire mesh configurations for niche applications) with minimal lead times.

- Smart Infrastructure Integration: Future applications may see integrated sensor technologies within mesh panels for structural health monitoring in civil engineering projects, or for enhanced security systems with real-time breach detection.

These innovations underscore a commitment to delivering high-performance, long-lasting products that meet the evolving demands of target industries such as petrochemical, metallurgy, and water supply & drainage, where material integrity is non-negotiable.

Application Scenarios Across Diverse Sectors

The versatility of galvanized welded wire mesh panel makes it an invaluable asset across a multitude of industries. Its robust construction and corrosion resistance make it suitable for both structural and protective applications.

- Construction & Civil Engineering: Used extensively for concrete reinforcement (roadways, foundations, precast elements), providing structural integrity and crack control. Also employed in gabion baskets for retaining walls and erosion control.

- Security & Fencing: High-security perimeter fencing, industrial security cages, machine guards, and window screens benefit from the strength and anti-climb properties of panels like 2x2 galvanized wire mesh.

- Agriculture & Animal Husbandry: Ideal for constructing durable and safe enclosures for livestock, poultry, and pets. The resistance to animal waste corrosion and ease of cleaning are significant advantages.

- Mining & Geotechnical: Rockfall protection, slope stabilization, and mine shaft lining systems utilize these panels for their strength and ability to withstand harsh underground conditions.

- Industrial & Manufacturing: Pallet racking infills, storage partitions, conveyor guards, and shelving units rely on the robustness and versatility of mesh panels.

- Water Treatment & Filtration: While not a primary filtration medium, larger mesh panels (e.g., 4x4 galvanized wire mesh) are used as support structures for filter media, screens for debris, or in various water intake structures due to their corrosion resistance.

In environments like petrochemical facilities, the corrosion resistance of these panels ensures safety and longevity, contributing to reduced maintenance cycles and enhanced operational efficiency. For water supply and drainage systems, the resistance to aqueous corrosion extends the lifespan of infrastructure components, proving their exceptional value.

Technical Advantages and Performance Metrics

The decision to specify a galvanized welded wire mesh panel over alternative materials is driven by its demonstrable technical advantages and superior performance metrics in demanding applications.

- Exceptional Corrosion Resistance: The zinc coating provides both barrier protection and cathodic protection to the underlying steel. This self-sacrificing property of zinc means it corrodes preferentially, protecting the steel even if the coating is scratched. This results in significantly extended service life, especially in outdoor or corrosive environments, far surpassing non-galvanized options. According to the American Galvanizers Association, hot-dip galvanized steel can last 50+ years in many environments.

- High Strength-to-Weight Ratio: The precise welding of high-tensile steel wires creates a rigid, robust structure that can withstand significant loads and impacts while remaining relatively lightweight compared to solid steel panels.

- Uniform Mesh & Dimensional Stability: The automated welding process ensures consistent mesh openings and flat, true panels, which are critical for applications requiring precise filtration, screening, or aesthetic uniformity.

- Ease of Fabrication & Installation: Panels can be easily cut, bent, and formed on-site or during prefabrication, simplifying installation and reducing labor costs. The rigid nature minimizes distortion during handling.

- Cost-Effectiveness & Low Maintenance: While initial costs may be higher than plain steel mesh, the long service life, minimal need for repainting or repair, and high durability lead to significantly lower life-cycle costs.

- Versatility: Available in a wide range of wire gauges and mesh sizes, from fine 1 8 galvanized wire mesh for critical screening to heavy 6x6 galvanized wire mesh for structural support, making it adaptable to diverse needs.

These advantages collectively contribute to projects that are safer, more durable, and more economically viable in the long run.

Comparing Solutions: Galvanized Welded Wire Mesh Panels vs. Alternatives

When selecting materials for industrial applications, a comparative analysis is essential. Here, we evaluate galvanized welded wire mesh panel against common alternatives.

Product Comparison Table:

| Feature | Galvanized Welded Wire Mesh Panel | Plain Steel Welded Wire Mesh | Woven Wire Mesh (Non-welded) | Expanded Metal Mesh |

|---|---|---|---|---|

| Corrosion Resistance | Excellent (Hot-dip zinc coating) | Poor (Rusts quickly) | Variable (Depends on material, often low for plain steel) | Variable (Galvanized options available, but higher cost) |

| Structural Rigidity | High (Welded intersections provide fixed aperture) | High (But prone to rust compromising welds) | Moderate (Wires can shift under stress) | Very High (No welds, integral structure) |

| Mesh Uniformity | Excellent (Precise, consistent openings like 2x2 galvanized wire mesh) | Excellent (Initially) | Good (But can deform) | Good (Pattern defined by cutting) |

| Life-Cycle Cost | Low (Long service life, minimal maintenance) | High (Frequent replacement/maintenance) | Moderate to High (Material dependent, potentially shorter life) | Moderate (Good durability but higher initial cost) |

| Weight | Moderate | Moderate | Lighter (often thinner wires) | Heavier (more material per area) |

The data unequivocally supports the selection of galvanized welded wire mesh panel for applications where durability, consistent performance, and low total cost of ownership are paramount. While initial material cost might be marginally higher than plain steel alternatives, the absence of frequent maintenance and replacement far outweighs this over the operational lifespan.

Customized Solutions and Engineering Capabilities

Recognizing that standard product offerings may not always perfectly align with unique project specifications, leading manufacturers provide extensive customization options for galvanized welded wire mesh panel. Our engineering team specializes in translating complex requirements into precise manufacturing specifications.

- Tailored Dimensions: Panels can be fabricated to virtually any specified width and length, minimizing material waste and cutting requirements on-site, which streamlines installation.

- Variable Mesh Openings: From dense 1 8 galvanized wire mesh for fine screening or rodent control to large 6x6 galvanized wire mesh for heavy-duty reinforcement or security, mesh sizes can be optimized for specific flow, visibility, or security needs.

- Specific Wire Gauges: Wire diameters can be selected to achieve precise load-bearing capacities, impact resistance, and overall rigidity.

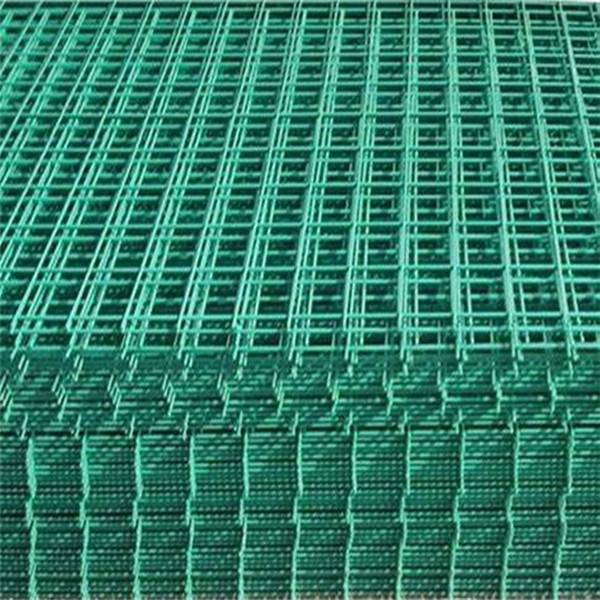

- Post-Galvanization Treatments: For extreme environments or aesthetic requirements, additional coatings such as PVC or powder coating can be applied over the galvanized layer, offering enhanced protection and color options.

- Integrated Features: Custom cut-outs, bent sections, and welded attachments can be incorporated into the panel design to facilitate integration into existing structures or to meet unique functional demands.

Our robust design and manufacturing capabilities, backed by ISO 9001 certification, ensure that customized solutions maintain the same high standards of quality and performance as our standard offerings, delivering optimal value for specialized projects.

Real-World Application Case Studies

Illustrating the practical benefits of galvanized welded wire mesh panel, these case studies highlight successful implementations across various industries.

Case Study 1: Petrochemical Facility Perimeter Security

A major petrochemical complex required a high-security perimeter fence capable of withstanding corrosive industrial atmospheres and offering robust intrusion deterrence. Traditional painted steel fencing had suffered rapid degradation. We supplied custom-fabricated 2x2 galvanized welded wire mesh panel with a 4mm wire gauge, hot-dip galvanized to ASTM A123 standards for a zinc coating of 610 g/m². The panels were also powder-coated black for enhanced UV protection and aesthetic integration.

- Outcome: The dual-coated galvanized mesh panels demonstrated exceptional resistance to chemical corrosion and saline exposure during accelerated weathering tests. After 5 years in service, the fence shows no signs of rust or degradation, significantly reducing maintenance costs and enhancing the facility's security posture.

Case Study 2: Water Treatment Plant Debris Screens

A municipal water treatment plant needed durable, corrosion-resistant screens for its primary intake channels to prevent large debris from entering the purification system. The screens needed to be robust enough to handle high flow rates and continuous submersion in water. We engineered custom-sized 4x4 galvanized wire mesh panels using 6mm thick wires, specifically designed for structural integrity and maximized flow.

- Outcome: The hot-dip galvanized panels have been submerged for over 10 years without significant signs of corrosion or structural fatigue. The robustness of the mesh has effectively protected downstream equipment, leading to reduced downtime and maintenance for debris removal.

These examples underscore the critical role of material science and precise manufacturing in delivering solutions that offer enduring performance and significant operational savings.

Quality Assurance, Certifications, and Compliance

Our commitment to quality is embedded in every stage of production for galvanized welded wire mesh panel. We adhere to stringent international standards and maintain comprehensive quality control protocols.

- ISO 9001:2015 Certification: Our manufacturing facilities operate under a certified Quality Management System, ensuring consistent quality from raw material sourcing to final product delivery.

- ASTM & EN Compliance: All products, including 6x6 galvanized wire mesh variants, comply with relevant ASTM (e.g., A1064/A1064M for steel wire, A123/A123M for hot-dip galvanizing) and EN (e.g., EN 10244-2 for zinc coatings, EN 10016 for steel rod) standards, guaranteeing material composition, coating thickness, and mechanical properties.

- Batch Traceability: Every panel batch is traceable back to its raw material source and production parameters, allowing for full transparency and accountability.

- In-house Testing: Our labs conduct routine tests for tensile strength, weld shear strength, zinc coating adhesion, and coating weight using calibrated equipment. Third-party testing can also be arranged upon request for independent verification.

- Years of Service: With over 20 years in the industry, we have a proven track record of delivering high-quality, reliable welded wire mesh solutions to a global clientele, including major industrial partners.

Our commitment to these rigorous standards provides clients with the assurance that they are receiving products of the highest caliber, built to perform reliably in their most critical applications.

Vendor Selection Criteria

Choosing the right supplier for galvanized welded wire mesh panel is as critical as selecting the product itself. B2B decision-makers should consider the following:

- Technical Expertise: A vendor's ability to provide detailed technical specifications, understand complex project requirements, and offer engineering support.

- Quality Certifications: Adherence to ISO, ASTM, and other relevant international standards. Verification of zinc coating thickness and weld integrity.

- Customization Capabilities: The flexibility to produce panels to exact specifications, including unique mesh sizes (e.g., a specific 2x2 galvanized welded wire mesh panel), wire gauges, and dimensions.

- Production Capacity & Lead Times: Ability to meet large volume orders and adhere to agreed-upon delivery schedules.

- After-Sales Support & Warranty: Clear warranty terms, responsive customer service, and technical support post-purchase.

- References & Track Record: Proven success with previous industrial clients and demonstrable experience in similar projects.

Lead Time, Fulfillment, and Logistics

Efficient logistics and transparent fulfillment processes are critical for B2B operations. We strive for predictable and timely delivery of all galvanized welded wire mesh panel orders.

- Standard Lead Time: For standard product configurations and common mesh sizes (e.g., 4x4 galvanized wire mesh), our typical lead time is 2-4 weeks from order confirmation, depending on volume.

- Custom Order Lead Time: Customized solutions may require 4-8 weeks, depending on complexity and material availability. Specific lead times are provided with each custom quote.

- Expedited Options: For urgent projects, expedited manufacturing and shipping options are available upon request and feasibility assessment.

- Packaging: Panels are securely bundled and strapped, often on wooden pallets or in crates, to prevent damage during transit. Custom packaging solutions are available for international shipments or specific handling requirements.

- Global Shipping: We leverage an extensive network of logistics partners to ensure efficient and reliable delivery to construction sites, warehouses, or ports worldwide. All necessary export documentation is handled in-house.

Our dedicated logistics team provides transparent communication throughout the order fulfillment process, including shipment tracking and proactive updates, ensuring your project timelines are met.

Warranty and After-Sales Support

Investing in a galvanized welded wire mesh panel from a reputable supplier means investing in long-term reliability. We stand behind the quality of our products with robust warranty provisions and dedicated after-sales support.

- Product Warranty: We offer a comprehensive 10-year limited warranty against manufacturing defects and premature corrosion under normal operating conditions for hot-dip galvanized products. Specific terms and conditions are provided with each purchase agreement.

- Technical Support: Our team of experienced engineers and product specialists is available to provide technical assistance, answer application-specific questions, and offer guidance on installation and maintenance.

- Customer Service: A dedicated customer service team ensures prompt resolution of any inquiries or issues, from order tracking to post-installation support.

- Replacement & Returns: In the rare event of a product defect, we facilitate efficient replacement or return processes in accordance with our warranty policy.

Our commitment extends beyond the point of sale, ensuring that our clients receive ongoing support and peace of mind throughout the lifespan of their galvanized welded wire mesh panel solutions.

Frequently Asked Questions (FAQ)

Q: What is the primary advantage of hot-dip galvanizing over electro-galvanizing for welded wire mesh panels?

A: Hot-dip galvanizing provides a significantly thicker and more durable zinc coating, creating a metallurgical bond with the steel. This multi-layered coating offers superior corrosion resistance and abrasion protection, leading to a much longer service life compared to the thinner, electro-plated zinc coating.

Q: Can galvanized welded wire mesh panels be cut or modified on-site?

A: Yes, panels can be cut using standard industrial tools like bolt cutters or angle grinders. However, it is crucial to apply a zinc-rich cold galvanizing compound or paint to any exposed cut edges to maintain corrosion resistance.

Q: Are different mesh sizes like 2x2, 4x4, or 6x6 galvanized wire mesh available for specific applications?

A: Absolutely. We offer a wide range of standard mesh openings, including 2x2 galvanized wire mesh, 4x4 galvanized wire mesh, and 6x6 galvanized wire mesh. Additionally, customized mesh sizes and wire gauges are available to meet unique project requirements for structural support, security, or containment.

Q: What industries primarily benefit from using galvanized welded wire mesh panels?

A: Key industries include construction (concrete reinforcement, gabions), agriculture (animal enclosures, fencing), mining (rockfall protection), manufacturing (machine guards, shelving), and infrastructure (bridges, water treatment facilities) due to its strength, durability, and corrosion resistance.

Q: How does the galvanized coating contribute to the environmental sustainability of the product?

A: The extended service life provided by galvanizing significantly reduces the need for frequent replacement, thereby conserving raw materials and energy associated with new production. Zinc is also 100% recyclable, contributing to a circular economy. The use of galvanized materials aligns with sustainable building practices by minimizing waste and environmental impact over the product's life cycle.

Conclusion

The galvanized welded wire mesh panel stands as a testament to engineering excellence, offering an unparalleled combination of strength, versatility, and enduring corrosion resistance. From its meticulous manufacturing process, adhering to global standards like ISO and ASTM, to its critical roles in diverse sectors such as petrochemical, metallurgy, and water management, these panels consistently deliver superior performance. The inherent technical advantages, coupled with robust customization options and unwavering quality assurance, position galvanized welded wire mesh as the optimal choice for B2B professionals seeking reliable, cost-effective, and long-lasting material solutions. By choosing galvanized welded wire mesh, industries can ensure structural integrity, enhance safety, and significantly reduce long-term operational costs, securing a durable foundation for their most demanding projects.

References

- American Galvanizers Association. (n.d.). Service Life of Hot-Dip Galvanized Steel. Retrieved from galvanizeit.org

- ASTM International. (2019). ASTM A123/A123M - 17: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. ASTM International, West Conshohocken, PA.

- ASTM International. (2018). ASTM A1064/A1064M - 18: Standard Specification for Steel Wire, Welded, for Concrete Reinforcement. ASTM International, West Conshohocken, PA.

- International Organization for Standardization. (2015). ISO 9001:2015: Quality management systems — Requirements. ISO, Geneva, Switzerland.

- International Organization for Standardization. (2009). ISO 1461:2009: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods. ISO, Geneva, Switzerland.

-

Durable PVC Coated Wire Mesh for Sale | Weather & Corrosion Resistant

NewsAug.28,2025

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NewsAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NewsAug.23,2025

-

Garden Edging Fence for Functional and Decorative Landscaping

NewsAug.23,2025

Products categories