mar . 05, 2025 01:40 Back to list

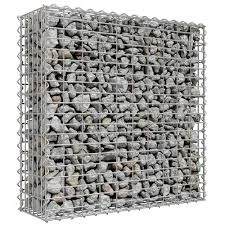

coated wire mesh

From an expertise standpoint, coated wire mesh also plays a significant role in industrial applications, such as in the realm of filtration and separation. With the ability to withstand chemical exposure and maintain structural integrity, coated wire meshes are used in filters requiring precision and longevity. The coating prevents the mesh from clogging, ensuring a smooth and consistent filtration process. Industries dealing with liquids or gases can thus rely on coated wire mesh for effective and safe operations, which contributes to the overall safety of industrial processes. It's essential to note the wide variety of the coated wire mesh options available in the market, ensuring adaptability and specificity for various applications. Understanding the particular needs of each project or industry can significantly influence the choice of coating material and wire gauge. By selecting the correct specifications, industries can significantly boost their operational efficacy and safety, leveraging the strength and resilience that coated wire mesh offers. Safety and compliance are also crucial considerations when implementing coated wire mesh in any setting. When properly manufactured and installed, coated wire mesh complies with international safety standards and regulations, ensuring that projects not only achieve their operational goals but also adhere to safety and environmental guidelines. This compliance underlines the authority and trustworthiness of the product in any engineering or construction application. In conclusion, the coated wire mesh is a sophisticated evolution of traditional wire mesh, offering enhanced performance, reliability, and safety across various industries. It stands as a testament to the innovations in materials engineering, bridging the gap between traditional manufacturing demands and modern-day practicalities. By embracing coated wire mesh's capabilities, industries can fortify their operations and ensure that their facilities stand the test of time with unwavering reliability. The multifaceted applications and proven track record of this product make it an indispensable choice for industry leaders aiming for excellence and sustainability in their projects.

-

Durable PVC Coated Wire Mesh for Sale | Weather & Corrosion Resistant

NewsAug.28,2025

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NewsAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NewsAug.23,2025

-

Garden Edging Fence for Functional and Decorative Landscaping

NewsAug.23,2025

Products categories