авг. . 17, 2025 04:00 Back to list

Durable Barbed Wire & Flat Mesh - Secure Fencing Solutions

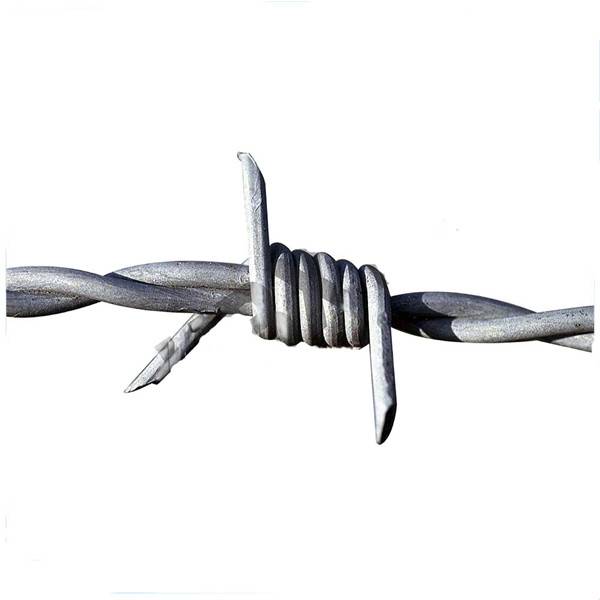

The Enduring Value of Galvanized Barbed Wire in Modern Security

In the realm of perimeter security and access control, barbed wire stands as a testament to simple yet highly effective deterrent technology, evolving significantly from its rudimentary origins to sophisticated, corrosion-resistant solutions. Our Barbed Wire With Galvanized Surface represents the pinnacle of this evolution, meticulously engineered to provide superior protection and longevity across a myriad of demanding environments. This product category, encompassing varieties like rbt barbed wire and flat barbed wire, is not merely a physical barrier but a strategic asset in comprehensive security infrastructure. Its design leverages high-tensile steel, meticulously processed through a hot-dip galvanization technique, which imbues it with an exceptional resistance to rust and environmental degradation. This inherent durability dramatically extends service life, reducing the total cost of ownership over time and making it an indispensable choice for both temporary and permanent installations. Understanding the intricate balance between material science and practical application is crucial for B2B decision-makers, as the right selection impacts not only security efficacy but also maintenance expenditure and operational continuity. The global market for perimeter security solutions continues to expand, driven by increasing geopolitical complexities, infrastructure protection needs, and agricultural demands, underscoring the sustained relevance and critical function of high-quality galvanized barbed wire in safeguarding assets and personnel.

Precision Manufacturing and Stringent Quality Assurance

The manufacturing process of our galvanized barbed wire is a carefully controlled sequence of operations designed to ensure unparalleled strength, durability, and resistance to environmental factors. It commences with the selection of premium high-carbon or low-carbon steel wire rods, which undergo a rigorous drawing process to achieve the precise wire gauge required for optimal tensile strength and barb formation. Following this, the drawn wire is subjected to hot-dip galvanization, a metallurgical bonding process where the steel is immersed in a bath of molten zinc. This process creates a uniform, resilient zinc coating that acts as a sacrificial layer, preventing the underlying steel from corroding, even in harsh atmospheric conditions. Unlike electro-galvanization, hot-dip galvanization forms a robust alloy layer between the steel and zinc, offering superior adhesion and protection. Post-galvanization, the individual strands are machine-twisted together, typically forming two-strand, four-point barbed wire, where precisely cut barbs are crimped onto one or both line wires at specified intervals. Our production adheres strictly to international standards such as ISO 9001 for quality management and ASTM A121 for metallic-coated steel barbed wire, ensuring every roll meets stringent specifications for wire diameter, zinc coating thickness, barb spacing, and tensile strength. This meticulous attention to detail at every stage, from raw material inspection to final product testing, guarantees a consistent, high-performance product with an estimated service life of 15-25 years in typical outdoor environments, significantly outperforming ungalvanized alternatives and reinforcing its suitability for critical applications in industries like petrochemicals, energy infrastructure, and agricultural containment.

Comprehensive Technical Specifications and Performance Metrics

Selecting the appropriate type of barbed wire necessitates a detailed understanding of its technical specifications and performance parameters, which directly influence its effectiveness and longevity in diverse applications. Our galvanized barbed wire comes in various configurations, including different wire gauges, barb designs, and roll lengths, tailored to meet specific security requirements. Common wire gauges range from 12.5 gauge (2.5mm) to 15.5 gauge (1.8mm) for the line wire, with barb wires typically of a slightly smaller diameter, designed to optimize both rigidity and cutting efficiency. Barb spacing, a critical parameter, can vary from 3 inches (7.6 cm) to 6 inches (15.2 cm), impacting the density of the deterrent points and thus the wire's effectiveness against intrusion. For instance, close barb spacing, often found in rbt barbed wire, provides a more aggressive barrier. The zinc coating thickness is measured in grams per square meter (g/m²) or ounces per square foot (oz/ft²), with heavy galvanization offering superior corrosion resistance for coastal or high-humidity environments. Our products exhibit high tensile strength, typically ranging from 450 to 800 MPa, ensuring the wire resists cutting, stretching, and tampering attempts. This robust construction makes it an ideal choice for applications demanding high-security perimeters, such as military installations, correctional facilities, and sensitive industrial sites, where the integrity of the barrier is paramount. Furthermore, variations like flat barbed wire, designed for neat installation on top of walls or fences, offer a distinct aesthetic while maintaining high security. The table below outlines key parameters for standard galvanized barbed wire, assisting technical buyers in making informed decisions aligned with project specifications and performance expectations, thereby ensuring optimal investment in security infrastructure.

| Parameter | Typical Range/Value | Measurement Unit |

|---|---|---|

| Line Wire Gauge | 12.5 to 15.5 | AWG / SWG |

| Barb Wire Gauge | 14 to 16 | AWG / SWG |

| Number of Strands | 2 | (Double Strand) |

| Number of Points | 2 or 4 | (Per Barb) |

| Barb Spacing | 3 to 6 | Inches |

| Zinc Coating Weight | 60 - 275 | g/m² |

| Tensile Strength (Line Wire) | 450 - 800 | MPa |

| Roll Length | 50 to 500 | Meters |

Versatile Applications Across Diverse Industrial and Commercial Landscapes

The adaptability and robust characteristics of galvanized barbed wire make it an indispensable component across an expansive range of industries and application scenarios, from agricultural boundaries to high-security defense installations. In the agricultural sector, it remains a primary choice for livestock containment and property demarcation, effectively preventing animal escapement and unauthorized entry due to its cost-effectiveness and ease of installation compared to other fencing types. For critical infrastructure, such as power stations, telecommunication hubs, and water treatment facilities, the use of barbed wire as a top-security enhancement on chain link or welded mesh fences significantly deters intrusion, reinforcing layered security protocols. Its resistance to corrosion, imparted by the galvanization, is particularly advantageous in outdoor environments exposed to varying weather conditions, including coastal regions or areas with high industrial pollution, where traditional iron barbed wire would rapidly degrade. Beyond conventional fencing, specialized forms like barbed wire mesh find utility in reinforcing security barriers or creating impenetrable cage-like structures. Similarly, when paired with high-tensile wire, it can form a robust barbed wire rope for enhanced barrier strength. While primarily known for security, its exceptional corrosion resistance also makes it valuable in peripheral roles within the petrochemical and metallurgical industries for securing perimeter fences around hazardous zones, ensuring compliance with safety regulations by restricting unauthorized access. This product’s longevity and low maintenance requirements translate into substantial long-term savings, offering a prudent investment for businesses seeking reliable and durable perimeter security solutions in challenging operational settings.

Strategic Advantages and Manufacturer Differentiation

Choosing the right galvanized barbed wire involves an in-depth evaluation of technical advantages and a discerning comparison between manufacturers. Our product distinguishes itself through its superior hot-dip galvanized coating, offering significantly enhanced corrosion resistance compared to lighter galvanized or PVC-coated alternatives, particularly in aggressive environments, thus extending its functional life and reducing the barbed wire cost over its lifecycle. While PVC coating offers aesthetic appeal and some additional corrosion protection, it can be susceptible to UV degradation and physical damage, compromising the underlying steel. Stainless steel barbed wire provides ultimate corrosion resistance but at a substantially higher initial investment, making it suitable only for highly specialized, niche applications where cost is not a primary constraint. Our commitment to stringent quality control, adhering to international standards like ISO and ASTM, ensures consistent product quality and performance metrics that few competitors can match. Furthermore, our substantial service history and numerous successful projects worldwide speak to our authoritative position in the industry. We invite potential clients to consider not just the initial purchase price but the long-term value, including minimal maintenance and extended replacement cycles, which translates into significant operational savings. Below is a comparative overview of different barbed wire types to aid in your procurement decision, highlighting the balance of cost-effectiveness, durability, and performance that our galvanized solution consistently delivers, positioning it as the optimal choice for the vast majority of commercial and industrial security applications that prioritize long-term reliability and value.

| Feature | Hot-Dip Galvanized | Electro-Galvanized | PVC Coated | Stainless Steel |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Very Good (if coating intact) | Superior |

| Service Life (Years) | 15-25+ | 5-10 | 10-20 (Coating dependent) | 25+ |

| Cost Efficiency | High | Moderate | Moderate-High | Low |

| Application | General Security, Agriculture, Industrial | Light-duty, Temporary | Residential, Aesthetic | Marine, Chemical, High-Value |

Customization Capabilities and Project-Specific Solutions

Recognizing that every B2B project presents unique challenges and specifications, we offer extensive customization capabilities for our galvanized barbed wire to ensure a perfect fit for diverse security infrastructure requirements. Our engineering team collaborates closely with clients to tailor solutions that address specific environmental conditions, threat levels, and budget constraints. Customization options extend to various parameters, including wire gauge (from lighter 15.5 gauge for agricultural uses to heavier 12.5 gauge for high-security applications), barb configuration (number of points and barb spacing), and critical zinc coating thickness to meet the demands of highly corrosive environments. For large-scale industrial or governmental projects, we can provide specific roll lengths, such as 100m barbed wire standard rolls or even longer, custom-sized spools to minimize splices and installation time for vast perimeter lines. Furthermore, beyond standard iron barbed wire, we can explore options for specific tensile strengths to counteract various cutting tools or impact forces. Our logistical expertise allows for efficient delivery cycles, crucial for projects with tight timelines, ensuring that customized orders are processed and shipped promptly without compromising on our rigorous quality standards. We leverage our deep industry experience to provide consulting services, advising on optimal product selection and installation techniques for enhanced security, drawing upon a portfolio of successful application cases ranging from critical infrastructure protection to international border security. This bespoke approach underscores our commitment to being more than just a supplier; we are a strategic partner dedicated to delivering comprehensive and highly effective security solutions for our global clientele.

Ensuring Reliability: Quality, Support, and Warranty Commitments

Our commitment to delivering unparalleled quality and fostering unwavering customer trust is foundational to our operations, especially concerning critical security products like galvanized barbed wire. We back our products with comprehensive quality assurance protocols, including adherence to ISO 9001 certification, which governs our manufacturing and operational processes, ensuring consistent excellence from raw material sourcing to final product delivery. Each batch of barbed wire undergoes rigorous testing for tensile strength, zinc coating adhesion, and overall structural integrity, with detailed test reports available upon request to verify compliance with specified standards. Our standard delivery cycle is optimized for efficiency, typically ranging from 2-4 weeks for standard orders, with expedited options available for urgent project requirements, communicated transparently through our dedicated client service portal. Furthermore, we provide a robust product warranty, covering manufacturing defects and premature corrosion under normal use conditions, demonstrating our confidence in the longevity and performance of our galvanized barbed wire. Our customer support team comprises seasoned professionals with deep technical knowledge of barbed wire applications, readily available to assist with product selection, installation guidance, and any post-purchase inquiries. We believe that true value extends beyond the product itself to the holistic support system that accompanies it. For instance, a recent client in the utilities sector praised our prompt delivery and the superior corrosion resistance of our product, which significantly reduced their maintenance costs in a humid, coastal environment, echoing similar feedback from agricultural and governmental clients who appreciate the reduced replacement frequency and high reliability of our barbed wire solutions. This comprehensive approach to quality, coupled with responsive support and transparent guarantees, solidifies our position as a trustworthy and authoritative partner in the B2B security sector.

Frequently Asked Questions (FAQ) About Galvanized Barbed Wire

Q1: What is the primary advantage of galvanized barbed wire over standard iron barbed wire?

The primary advantage of galvanized barbed wire lies in its superior corrosion resistance. Standard iron barbed wire is highly susceptible to rust and degradation when exposed to elements, leading to a significantly shorter service life and increased maintenance or replacement costs. The hot-dip galvanization process applies a protective zinc coating that acts as a barrier and a sacrificial anode, dramatically extending the wire's lifespan, especially in harsh weather conditions or corrosive environments, making it a more economical and reliable long-term solution for perimeter security.

Q2: How does the "100m barbed wire" standard length compare to other coil sizes, and what are its typical applications?

The "100m barbed wire" coil is a widely recognized and frequently utilized standard length in the industry, offering a balanced combination of manageability and coverage for various applications. While coils can range from 50 meters to several hundred meters, the 100m length is particularly convenient for agricultural fencing, residential property demarcation, and small to medium-sized commercial security installations where continuous long runs are not always necessary. It provides sufficient length for most common fencing projects without being excessively heavy or cumbersome to transport and install, making it a popular choice for contractors and end-users alike who require a practical and efficient solution for creating effective barriers.

Q3: Can galvanized barbed wire be easily cut or breached, and what measures enhance its security?

While no physical barrier is entirely impenetrable, galvanized barbed wire is designed to be highly resistant to casual breaching attempts due to its sharp barbs and high tensile strength, which deters unauthorized access. To enhance its security, several measures can be employed: combining it with other fencing types such as chain link or welded mesh fences (often as a top deterrent), using multiple strands or coils for increased density, incorporating it into rbt barbed wire or concertina coil designs for a more formidable obstacle, and ensuring proper installation with sturdy posts and tensioning. These multi-layered approaches significantly increase the time and effort required for a breach, making the barbed wire an effective component of a comprehensive security system that aims to delay and deter intruders.

Conclusion

As a cornerstone of robust perimeter security, galvanized barbed wire continues to prove its invaluable efficacy across an array of applications, offering a compelling blend of cost-effectiveness, enduring performance, and versatile deployment capabilities. Our Barbed Wire With Galvanized Surface is not merely a product but a highly engineered solution designed to meet the rigorous demands of modern B2B security challenges. Through meticulous manufacturing processes, adherence to stringent international standards, and a deep understanding of market needs, we deliver a product that guarantees extended service life, superior corrosion resistance, and unwavering reliability. For decision-makers in industries ranging from agriculture to critical infrastructure and defense, investing in our galvanized barbed wire translates into a strategic advantage, securing assets and personnel with minimal long-term operational expenditure. We remain committed to innovation, customer-centric solutions, and building lasting partnerships based on trust and demonstrated expertise. Choosing our product is choosing a legacy of protection and a future of uncompromised security.

Authoritative References:

- American Society for Testing and Materials (ASTM) International. "ASTM A121 - 13(2021) Standard Specification for Metallic-Coated Steel Barbed Wire."

- International Organization for Standardization (ISO). "ISO 1461:2009 Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods."

- Galvanizers Association. "The Performance of Galvanized Steel in Various Environments."

-

build-a-discreet-chicken-run-with-sturdy-green-coated-chicken-wire

NewsAug.23,2025

-

a-guide-to-selecting-the-most-durable-field-gates-for-your-property

NewsAug.23,2025

-

green-mesh-fencing-rolls-offer-versatile-solutions-for-diverse-needs

NewsAug.23,2025

-

chain-fence-for-durable-and-versatile-enclosure-solutions

NewsAug.23,2025

-

garden-edging-fence-for-functional-and-decorative-landscaping

NewsAug.23,2025

-

3d-wire-mesh-fence-for-versatile-security-and-decoration

NewsAug.23,2025

Products categories