авг. . 13, 2025 04:00 Back to list

Durable Barbed Wire & Flat Mesh for Secure Fencing

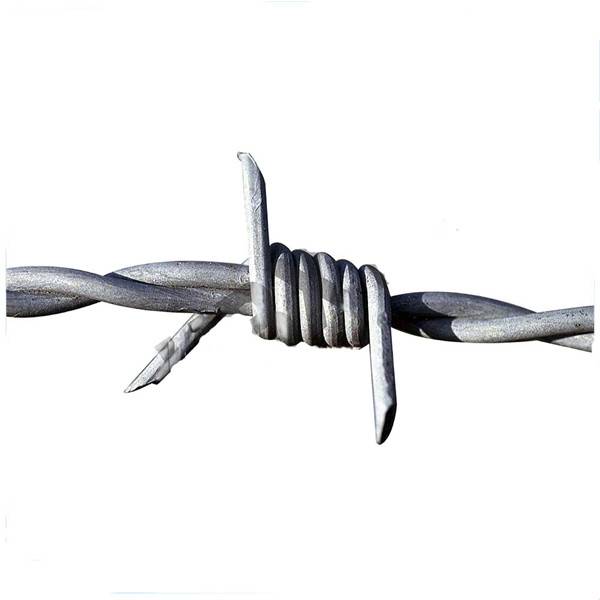

Understanding Barbed Wire: A Strategic Asset in Perimeter Security

In the realm of perimeter security and boundary demarcation, barbed wire stands as a foundational and highly effective deterrent. Its efficacy stems from a deceptively simple yet ingeniously engineered design: multiple strands of wire interwoven with sharp barbs at regular intervals. Historically, its application spanned agricultural fencing to military fortifications, and today, it remains indispensable across diverse sectors demanding robust security solutions. The latest industry trends indicate a growing demand for specialized variants, such as those with enhanced corrosion resistance and improved tensile strength, driven by increasing global security concerns and the need for durable, low-maintenance installations. Understanding the technical specifications, material science, and manufacturing processes of modern barbed wire is paramount for B2B decision-makers seeking optimal security infrastructure investments.

Technical parameters, including wire gauge, barb spacing, and coating type, directly impact the security level and longevity of an installation. For instance, a heavier wire gauge (lower BWG number) offers greater resistance to cutting, while specific galvanization processes significantly extend service life in corrosive environments. The cost-effectiveness of barbed wire, combined with its formidable deterrent capability, makes it a preferred choice for large-scale boundary protection where comprehensive, visible security is required.

The Advanced Manufacturing Process of Galvanized Barbed Wire

The production of high-quality barbed wire with a galvanized surface is a meticulously controlled industrial process designed to ensure durability, strength, and superior corrosion resistance. Unlike complex machining operations, the core of barbed wire manufacturing focuses on precision wire drawing, effective surface treatment, and automated twisting. The primary material typically used is high-grade low-carbon steel wire, selected for its optimal balance of ductility for manufacturing and tensile strength for security applications.

The process begins with wire rod procurement, followed by multiple stages of cold wire drawing, which reduces the wire's diameter to the desired gauge while enhancing its mechanical properties, including tensile strength and hardness. Post-drawing, the wires undergo galvanization, a critical step that imparts corrosion resistance. Hot-dip galvanizing, compliant with standards like ASTM A121, involves immersing the steel wire in a bath of molten zinc. This process creates a metallurgical bond between the zinc coating and the steel substrate, offering robust protection against rust and environmental degradation, significantly extending the product's service life, especially in coastal, industrial, or agricultural environments prone to moisture and chemical exposure.

Following galvanization, the wires are fed into specialized barbed wire machines. These machines precisely twist two or more line wires together, simultaneously adding sharp, uniformly spaced barbs from a separate barb wire. This automated twisting ensures consistent barb spacing and secure attachment, preventing slippage or easy manipulation. Quality control checkpoints are integrated throughout the process, adhering to international standards such as ISO 9001, to monitor wire gauge, zinc coating thickness, barb uniformity, and overall structural integrity. This rigorous adherence to manufacturing and testing standards ensures the final product meets stringent performance requirements for various applications, including large-scale perimeter fencing in industrial complexes, agricultural holdings, and critical infrastructure, demonstrating superior deterrence and long-term viability against environmental factors.

Technical Specifications & Performance Metrics

Selecting the appropriate barbed wire for specific applications requires a detailed understanding of its technical specifications. These parameters dictate the product's strength, durability, and effectiveness as a security barrier. Key specifications include the wire gauge (often expressed in BWG - Birmingham Wire Gauge), the number of strands, barb configuration (e.g., 2-point, 4-point), and barb spacing. For instance, a common specification is 12.5 BWG (2.5mm wire diameter) for heavy-duty applications, while 15.5 BWG (1.8mm) might suffice for lighter agricultural use. The galvanized coating thickness is also a critical metric, typically measured in grams per square meter (g/m²), indicating the level of corrosion protection. Higher coating weights translate to extended service life, particularly in harsh environmental conditions.

The performance of barbed wire is directly correlated with these specifications. Tensile strength, measured in megapascals (MPa), indicates the wire's resistance to breaking under tension, a crucial factor for preventing unauthorized breaches. Elongation, the percentage by which a wire can stretch before breaking, speaks to its flexibility and resistance to sudden impacts. Compliance with international standards such as ASTM A121 ensures that manufacturers adhere to minimum performance benchmarks for metallic-coated carbon steel barbed wire. This comprehensive approach to material science and engineering ensures that each product, from standard 100m barbed wire rolls to specialized rbt barbed wire variants, delivers reliable, long-lasting security. Below is a detailed table outlining common specifications for galvanized barbed wire, aiding in informed procurement decisions.

Common Galvanized Barbed Wire Specifications

| Parameter | Description | Typical Range/Value | Relevant Standard |

|---|---|---|---|

| Material | High-quality Low Carbon Steel Wire | Q195, Q235 | ASTM A121, ISO 16120 |

| Surface Treatment | Corrosion-resistant zinc coating | Hot-Dip Galvanized, Electro Galvanized | ASTM A90, ISO 1461 |

| Wire Gauge (Line Wire) | Diameter of the main strands | 12 BWG - 16 BWG (2.5mm - 1.6mm) | ASTM A121 |

| Wire Gauge (Barb Wire) | Diameter of the barb wire | 14 BWG - 18 BWG (2.0mm - 1.2mm) | ASTM A121 |

| Number of Strands | How many main wires twisted together | 2-strand, 4-strand | N/A |

| Barb Spacing | Distance between barb clusters | 7.5 cm - 15 cm (3-6 inches) | N/A |

| Tensile Strength | Resistance to breaking under tension | 350-550 MPa | ASTM A121 |

| Zinc Coating Weight | Amount of zinc per unit area | Minimum 40 g/m² (Electro), 200-300 g/m² (Hot-dip) | ASTM A90, ISO 1461 |

Diverse Application Scenarios and Strategic Advantages

The versatility of barbed wire allows its deployment across a multitude of sectors, from critical infrastructure protection to agricultural land management. In high-security environments such as airports, military bases, correctional facilities, and industrial complexes (including petrochemical and energy plants), barbed wire serves as an effective first line of defense, deterring unauthorized access and discouraging climbing attempts. Its ability to create an imposing physical barrier complements electronic surveillance systems, forming a multi-layered security approach. Furthermore, for large-scale agricultural operations, it provides a cost-effective and durable solution for livestock containment and property demarcation, preventing both animal escape and trespass. The robustness of iron barbed wire, especially when hot-dip galvanized, ensures longevity in diverse climates, reducing the need for frequent maintenance.

Beyond traditional fencing, specialized forms like flat barbed wire and barbed wire mesh expand its utility. Flat barbed wire, often used for razor wire installations, provides a compact yet highly aggressive barrier suitable for urban security perimeters. Barbed wire mesh, which combines the deterrent properties of individual strands into a cohesive fence panel, offers enhanced structural integrity and quicker installation for certain applications. The technical advantages of using galvanized barbed wire include its exceptional corrosion resistance, crucial for long-term outdoor exposure; high tensile strength, preventing easy cutting or manipulation; and relatively low barbed wire cost compared to other high-security fencing options. These attributes make it an economically viable and highly reliable solution for large-scale security projects, offering superior deterrence and operational efficiency without compromising on safety.

Customization, Quality Assurance, and Customer Support

Recognizing that security needs vary significantly across industries and projects, reputable manufacturers offer comprehensive customization options for barbed wire. This includes tailoring parameters such as wire gauge, barb spacing, galvanization thickness, and coil length (e.g., standard 100m barbed wire coils or custom lengths) to meet specific performance requirements and budget constraints. For specialized applications like anti-climb barriers, variations of rbt barbed wire or concertina coil options can be provided. This flexible approach ensures that clients receive a product perfectly suited to their operational environment and security objectives, whether it's for protecting sensitive industrial sites or securing vast agricultural properties.

Our commitment to quality is underpinned by adherence to rigorous industry standards and certifications. Our products undergo stringent testing to comply with international norms like ISO 9001 for quality management and relevant ASTM standards for material specifications and galvanization. This ensures that every batch of barbed wire, including high-strength barbed wire rope variants, meets the highest benchmarks for durability and performance. We provide comprehensive technical documentation, including material test reports and galvanization certificates, empowering B2B clients with the assurance of product integrity. With a service tenure spanning over a decade, our experience in delivering robust security solutions to diverse industrial clients underscores our authoritativeness in the field. Our dedicated customer support team is available to assist with technical queries, product selection, and provide post-sales support, ensuring a seamless procurement and deployment experience. We offer transparent delivery schedules and stand behind our products with a robust warranty, reinforcing trustworthiness and long-term client relationships.

Frequently Asked Questions (FAQ)

-

Q1: What is the typical service life of galvanized barbed wire?

A1: The service life of galvanized barbed wire largely depends on the thickness of its zinc coating and the environmental conditions. Hot-dip galvanized barbed wire with a heavy zinc coating (e.g., 200-300 g/m²) can last 20-30 years or more in moderate climates. In highly corrosive environments, such as coastal areas or industrial zones with chemical exposure, the lifespan may be reduced but still significantly longer than non-galvanized options, often exceeding 10-15 years. Electro-galvanized wire offers a shorter lifespan due to a thinner coating but is suitable for less demanding applications.

-

Q2: How does hot-dip galvanization compare to electro-galvanization for barbed wire?

A2: Hot-dip galvanization involves immersing steel wire in molten zinc, creating a thick, durable, and metallurgically bonded zinc layer. This provides superior corrosion resistance and a longer lifespan, making it ideal for outdoor and harsh environments. Electro-galvanization, conversely, applies a thinner zinc coating through an electrolytic process, resulting in a smoother, brighter finish but offering less corrosion protection and a shorter service life. For critical security infrastructure, hot-dip galvanized barbed wire is the preferred choice due to its enhanced durability and weather resistance.

-

Q3: Can barbed wire be customized for specific project requirements?

A3: Yes, most reputable manufacturers offer extensive customization options. This includes varying the wire gauge, barb configuration (e.g., 2-point, 4-point), barb spacing, coil length, and zinc coating thickness. Specialized variants like flat barbed wire, concertina coils, or specific high-tensile barbed wire rope for enhanced security can also be produced to meet unique project demands. Providing detailed specifications allows manufacturers to tailor the product to the exact needs of your security application, optimizing both performance and barbed wire cost.

-

Q4: What is the typical delivery timeframe for large orders?

A4: Delivery timeframes for large orders of barbed wire can vary based on quantity, customization requirements, and current production schedules. Typically, standard product orders can be fulfilled within 2-4 weeks. For highly customized or exceptionally large volumes, the lead time may extend to 4-8 weeks. We maintain transparent communication regarding production and shipping schedules and work diligently to meet project deadlines. Expedited options may be available for urgent requirements upon discussion with our sales team.

Authoritative References and Industry Standards

The information presented herein is underpinned by industry best practices and standards, ensuring accuracy and reliability for technical decision-makers. Adherence to these standards is crucial for guaranteeing the quality, performance, and safety of barbed wire products in demanding B2B applications.

- ASTM A121 – Standard Specification for Metallic-Coated Carbon Steel Barbed Wire. This standard defines the requirements for various types and finishes of barbed wire, ensuring consistency in material properties and construction.

- ISO 9001 – Quality Management Systems. This international standard outlines the criteria for a quality management system, ensuring that products and services consistently meet customer and regulatory requirements.

- ASTM A90/A90M – Standard Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings. This method is critical for verifying the integrity and thickness of the galvanized coating, directly impacting the product's corrosion resistance.

- ISO 16120 – Non-alloy steel wire rod for conversion to wire. Parts 1-4 cover the general requirements and specific requirements for general purpose, specific applications, special applications, and welding applications, ensuring the base steel quality.

-

build-a-discreet-chicken-run-with-sturdy-green-coated-chicken-wire

NewsAug.23,2025

-

a-guide-to-selecting-the-most-durable-field-gates-for-your-property

NewsAug.23,2025

-

green-mesh-fencing-rolls-offer-versatile-solutions-for-diverse-needs

NewsAug.23,2025

-

chain-fence-for-durable-and-versatile-enclosure-solutions

NewsAug.23,2025

-

garden-edging-fence-for-functional-and-decorative-landscaping

NewsAug.23,2025

-

3d-wire-mesh-fence-for-versatile-security-and-decoration

NewsAug.23,2025

Products categories