лют . 13, 2025 11:33 Back to list

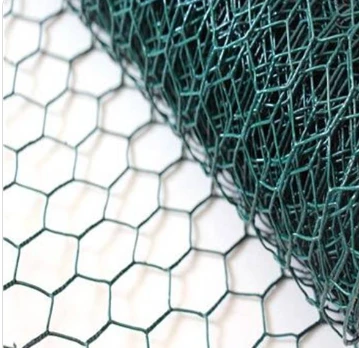

welding mesh sizes

Welding mesh sizes play a crucial role in various construction and industrial applications, offering a versatile solution for reinforcement, partitioning, and containment. Selecting the appropriate welding mesh size requires a nuanced understanding of its impact on structural integrity, cost-efficiency, and project success.

Authoritativeness in this domain comes from a deep comprehension of both industry standards and innovative production techniques. Leading manufacturers often employ state-of-the-art technology to produce welding mesh that meets rigorous quality controls and environmental standards. Engaging with these manufacturers or even visiting production lines can provide invaluable insights into the nuances of mesh size selection and the latest trends in material science that influence these choices. Moreover, collaboration with industry experts and participation in trade missions or exhibitions can reveal cutting-edge applications and emerging technologies that could be leveraged to increase the effectiveness of a particular mesh size in a given project. Trustworthiness is established through adherence to ethical procurement practices and long-term reliability of product performance. Vetting suppliers for compliance with environmental and safety standards ensures that the mesh products are not only safe and durable but also responsibly sourced. Prolonged partnerships with reputable manufacturers can also guarantee consistent quality, reducing the risk of structural failures or project delays due to material deficiencies. Builders and contractors who prioritize these factors are likely to enjoy long-lasting and trust-based relationships with their clients, stemming from the assurance that every aspect of their reinforcement materials has been meticulously evaluated. In conclusion, welding mesh sizes are more than just a functional consideration; they represent a critical element of project planning and execution that combines expertise, experience, and an unwavering commitment to quality and ethical standards. By understanding the implications of different mesh sizes, professionals in the construction and industrial sectors can optimize their projects for both performance and cost-efficiency, ensuring that the end product truly stands the test of time.

Authoritativeness in this domain comes from a deep comprehension of both industry standards and innovative production techniques. Leading manufacturers often employ state-of-the-art technology to produce welding mesh that meets rigorous quality controls and environmental standards. Engaging with these manufacturers or even visiting production lines can provide invaluable insights into the nuances of mesh size selection and the latest trends in material science that influence these choices. Moreover, collaboration with industry experts and participation in trade missions or exhibitions can reveal cutting-edge applications and emerging technologies that could be leveraged to increase the effectiveness of a particular mesh size in a given project. Trustworthiness is established through adherence to ethical procurement practices and long-term reliability of product performance. Vetting suppliers for compliance with environmental and safety standards ensures that the mesh products are not only safe and durable but also responsibly sourced. Prolonged partnerships with reputable manufacturers can also guarantee consistent quality, reducing the risk of structural failures or project delays due to material deficiencies. Builders and contractors who prioritize these factors are likely to enjoy long-lasting and trust-based relationships with their clients, stemming from the assurance that every aspect of their reinforcement materials has been meticulously evaluated. In conclusion, welding mesh sizes are more than just a functional consideration; they represent a critical element of project planning and execution that combines expertise, experience, and an unwavering commitment to quality and ethical standards. By understanding the implications of different mesh sizes, professionals in the construction and industrial sectors can optimize their projects for both performance and cost-efficiency, ensuring that the end product truly stands the test of time.

Pervious:

Latest news

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US