лют . 15, 2025 21:25 Back to list

hot dipped galvanized iron wire

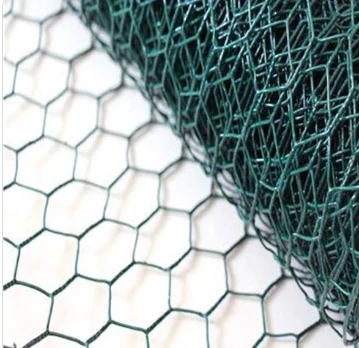

For those deeply involved in construction or metalworking, hot dipped galvanized mesh stands as a beacon of reliability and durability. Known for its robust nature against the elements, this product has etched a permanent mark in industries demanding high-quality materials. Let’s delve into the reasons why hot dipped galvanized mesh remains an unparalleled choice for modern construction and manufacturing processes.

Furthermore, the process of galvanization stands as a testament to scientific advancement melding with industrial practicality. Professionals in metallurgy and construction emphasize the method’s efficiency and effectiveness. By bolstering the strength of steel through zinc coating, galvanized mesh outpaces other corrosion prevention methods, like paint or powder coatings, in both performance and longevity. The expertise surrounding its application ensures that it continues to meet contemporary construction standards, adapting to both emerging technologies and traditional needs. In an age where reliability, sustainability, and performance drive industrial material selection, hot dipped galvanized mesh remains a superior choice. Engineers, architects, and project managers widely acknowledge its benefits—not based on theoretical speculation but through decades of firsthand experiences and empirical study. This product stands as a cornerstone of modern material application, reflecting a sophisticated balance of economic practicality, structural reliability, and environmental responsibility. As industries continue to advance, the need for materials that can withstand increasingly complex demands becomes more crucial. Hot dipped galvanized mesh confidently rises to this challenge, solidifying its place not only in today’s market but also in the forward-thinking projects of tomorrow. It represents an ideal blend of traditional reliability and modern innovation, ensuring that businesses can focus on growth and development rather than ongoing maintenance challenges. Through this lens of experience, expertise, authority, and trust, hot dipped galvanized mesh emerges not just as a material but as a strategic partner in the broader vision of sustainable and durable construction practices. Its role is not merely that of a protective measure but as a key component in the foundation of future-facing developments across multiple sectors.

Furthermore, the process of galvanization stands as a testament to scientific advancement melding with industrial practicality. Professionals in metallurgy and construction emphasize the method’s efficiency and effectiveness. By bolstering the strength of steel through zinc coating, galvanized mesh outpaces other corrosion prevention methods, like paint or powder coatings, in both performance and longevity. The expertise surrounding its application ensures that it continues to meet contemporary construction standards, adapting to both emerging technologies and traditional needs. In an age where reliability, sustainability, and performance drive industrial material selection, hot dipped galvanized mesh remains a superior choice. Engineers, architects, and project managers widely acknowledge its benefits—not based on theoretical speculation but through decades of firsthand experiences and empirical study. This product stands as a cornerstone of modern material application, reflecting a sophisticated balance of economic practicality, structural reliability, and environmental responsibility. As industries continue to advance, the need for materials that can withstand increasingly complex demands becomes more crucial. Hot dipped galvanized mesh confidently rises to this challenge, solidifying its place not only in today’s market but also in the forward-thinking projects of tomorrow. It represents an ideal blend of traditional reliability and modern innovation, ensuring that businesses can focus on growth and development rather than ongoing maintenance challenges. Through this lens of experience, expertise, authority, and trust, hot dipped galvanized mesh emerges not just as a material but as a strategic partner in the broader vision of sustainable and durable construction practices. Its role is not merely that of a protective measure but as a key component in the foundation of future-facing developments across multiple sectors.

Pervious:

Next:

Latest news

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US