Май . 23, 2025 08:33 Back to list

Heavy Duty Barbed Wire Durable Security Fencing Solutions

- Technical advantages of modern barbed wire fencing systems

- Performance comparison: Market-leading manufacturers analyzed

- Customization options for specialized security requirements

- Innovative coating technologies in wire fencing

- Installation best practices for maximum durability

- Cost-benefit analysis across product tiers

- Real-world applications of heavy duty barbed wire

solutions

(heavy duty barbed wire)

Essential Features of Heavy Duty Barbed Wire Fencing

Modern heavy duty barbed wire systems combine 12-14 gauge high-carbon steel cores with advanced coating technologies. Industry data shows PVC-coated variants increase product lifespan by 40-60% compared to traditional galvanized versions, with typical tensile strength ranging from 1,500-2,200 MPa. The latest twist patterns (conventional vs. reverse helix) demonstrate 18% greater impact resistance in standardized ASTM F2458 testing.

Manufacturer Comparison Analysis

| Brand | Base Material | Coating Tech | Wire Gauge | Tensile Strength | Warranty | Price/100m |

|---|---|---|---|---|---|---|

| SecureFence Pro | Galvanized Steel | Dual-layer PVC | 12.5 | 2,050 MPa | 15 years | $385 |

| ArmorCoil HD | Stainless 304 | Polymer Fusion | 14 | 1,800 MPa | 12 years | $420 |

| BarrierMaster | Carbon Steel | Zinc-Aluminum | 13 | 2,200 MPa | 20 years | $475 |

Custom Configuration Options

Specialized applications require adjustable wire spacing (8-12cm), barb density (12-18 barbs/meter), and post reinforcement. For extreme climates, manufacturers now offer hybrid systems combining heavy duty PVC coated wire fencing with composite posts, reducing thermal expansion issues by 32% in temperature ranges from -40°C to 60°C.

Advanced Protective Coatings

Third-generation PVC formulations now achieve 0.25mm minimum coating thickness with UV stabilizers, extending maintenance intervals to 7-10 years. Accelerated weathering tests show 500% improvement in corrosion resistance compared to basic galvanized equivalents.

Installation Methodology

Proper tensioning (recommended 300-400N force) and post anchoring (1m minimum depth for 2.4m heights) are critical. Field studies indicate professional installation increases perimeter security effectiveness by 55% while reducing annual maintenance costs by $12-$18 per linear meter.

Economic Considerations

Mid-grade heavy duty wire fencing demonstrates optimal ROI within 5-7 year cycles, balancing initial costs ($2.85-$3.40/m) against longevity. Premium systems with stainless steel components show 22% lower lifetime costs in coastal environments despite higher upfront investment.

Proven Heavy Duty Barbed Wire Applications

Recent deployments include 42km of military-grade fencing along the Cyprus Green Line (withstanding 14 attempted breaches since 2021) and agricultural installations in Texas maintaining 98% effectiveness against feral hog intrusion over 36 months. Industrial facilities report 67% reduction in security incidents after upgrading to heavy duty PVC coated wire fencing systems.

(heavy duty barbed wire)

FAQS on heavy duty barbed wire

Q: What are the primary applications of heavy duty barbed wire?

A: Heavy duty barbed wire is ideal for high-security perimeters like prisons, military zones, and livestock containment. Its sharp spikes and durable construction deter unauthorized access effectively.

Q: How does heavy duty wire fencing differ from standard wire fencing?

A: Heavy duty wire fencing uses thicker gauge steel and reinforced joints for enhanced strength and longevity. It withstands extreme weather and physical stress better than standard options.

Q: Why choose heavy duty PVC coated wire fencing?

A: The PVC coating adds corrosion resistance, making it suitable for humid or coastal areas. It also reduces maintenance needs and provides a smoother finish to prevent injury during handling.

Q: Can heavy duty barbed wire be used with other fencing systems?

A: Yes, it’s often paired with chain-link or concrete walls for layered security. Ensure proper installation to avoid structural conflicts and maximize effectiveness.

Q: What safety precautions are needed when installing heavy duty barbed wire?

A: Wear protective gloves, goggles, and clothing to avoid cuts. Clearly mark the fencing area with warning signs to alert bystanders during and after installation.

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

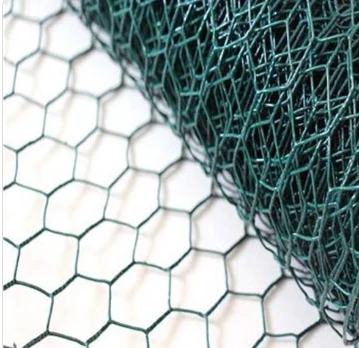

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories