Custom Made Galvanized Hexagonal Wire Netting Chicken Wire Mesh

Home>News>Custom Made Galvanized Hexagonal Wire Netting Chicken Wire Meshлют . 15, 2025 16:54 Back to list

Custom Made Galvanized Hexagonal Wire Netting Chicken Wire Mesh

In the realm of construction, agriculture, and various industrial applications, galvanized wire mesh screens hold a significant place. Their multifaceted utility is inextricably linked with their durability, resistance to rust, and adaptability in various environmental conditions. The transformative galvanization process enhances the steel or iron mesh's resilience, ensuring that it stands up to the rigors of both indoor and outdoor use. This article delves into the myriad advantages of galvanized wire mesh screens, drawing from both expert insights and real-world experiences.

On the topic of sustainability, galvanized wire mesh screens align with the modern demand for environmentally accountable practices. The zinc used in galvanization is recyclable, thus presenting an eco-friendlier option compared to certain plastic or less durable materials which may not withstand the test of time. For businesses looking to adopt sustainable practices without compromising on quality, this provides a viable path forward. Experts also recognize the customizable nature of galvanized wire mesh. Available in a variety of sizes, thicknesses, and finishes, it can be tailor-fit to specific project needs. Whether it is a fine mesh for a precise filtration system or a heavier gauge for structural support, the customization options are extensive, allowing seamless integration into any project plan. From firsthand accounts, users frequently praise the ease of installation that galvanized wire mesh screens offer. Unlike some materials that necessitate specialized equipment or significant labor, these screens can often be installed with basic tools, reducing both time and expense. This practical insight is often underlined by contractors who consistently choose galvanized mesh for projects where time efficiency is as crucial as the end result. On the spectrum of credibility, the longevity and historical reliability of galvanized wire mesh are well-documented. This is not merely promotional rhetoric; it is backed by empirical data and case studies illustrating its application and resilience in significant global infrastructure and agricultural projects. Researchers and industry stakeholders often highlight these findings in publications and forums, reinforcing the trusted status of galvanized wire mesh within the professional community. In conclusion, the galvanized wire mesh screen is more than just a construction material; it is a testament to innovation, efficiency, and adaptability. Its ability to meet the demands of various industries while upholding principles of sustainability and cost-effectiveness places it at the forefront of preferred materials. For professionals and consumers alike, galvanized wire mesh remains an authoritative choice, ensuring quality and reliability in every application.

On the topic of sustainability, galvanized wire mesh screens align with the modern demand for environmentally accountable practices. The zinc used in galvanization is recyclable, thus presenting an eco-friendlier option compared to certain plastic or less durable materials which may not withstand the test of time. For businesses looking to adopt sustainable practices without compromising on quality, this provides a viable path forward. Experts also recognize the customizable nature of galvanized wire mesh. Available in a variety of sizes, thicknesses, and finishes, it can be tailor-fit to specific project needs. Whether it is a fine mesh for a precise filtration system or a heavier gauge for structural support, the customization options are extensive, allowing seamless integration into any project plan. From firsthand accounts, users frequently praise the ease of installation that galvanized wire mesh screens offer. Unlike some materials that necessitate specialized equipment or significant labor, these screens can often be installed with basic tools, reducing both time and expense. This practical insight is often underlined by contractors who consistently choose galvanized mesh for projects where time efficiency is as crucial as the end result. On the spectrum of credibility, the longevity and historical reliability of galvanized wire mesh are well-documented. This is not merely promotional rhetoric; it is backed by empirical data and case studies illustrating its application and resilience in significant global infrastructure and agricultural projects. Researchers and industry stakeholders often highlight these findings in publications and forums, reinforcing the trusted status of galvanized wire mesh within the professional community. In conclusion, the galvanized wire mesh screen is more than just a construction material; it is a testament to innovation, efficiency, and adaptability. Its ability to meet the demands of various industries while upholding principles of sustainability and cost-effectiveness places it at the forefront of preferred materials. For professionals and consumers alike, galvanized wire mesh remains an authoritative choice, ensuring quality and reliability in every application.

Latest news

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

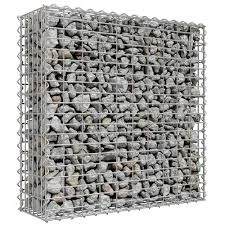

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US