Custom Made Galvanized Hexagonal Wire Netting Chicken Wire Mesh

Home>News>Custom Made Galvanized Hexagonal Wire Netting Chicken Wire Meshлют . 15, 2025 06:24 Back to list

Custom Made Galvanized Hexagonal Wire Netting Chicken Wire Mesh

Galvanized diamond mesh, an essential component in various construction and industrial applications, stands as a testament to both durability and functionality. This article delves into its multifaceted uses, its manufacturing intricacies, and why it remains a preferred choice among professionals worldwide.

The manufacturing process of galvanized diamond mesh speaks volumes of its quality assurance. Each batch undergoes rigorous testing to make sure it meets industry standards. Companies producing high-quality galvanized diamond mesh are known for their stringent quality control policies, ensuring that each piece is capable of withstanding harsh environmental conditions without succumbing to wear and tear. A crucial aspect that underscores the authoritative nature of galvanized diamond mesh is the widespread endorsement by countless engineers and builders. Their continued reliance on this material is a testament to its trustworthiness in critical applications. Many industry professionals provide firsthand accounts of its reliability, often highlighting reduced maintenance costs and longevity as key advantages over alternative materials. Moreover, the sustainability factor cannot be overlooked. The galvanized diamond mesh is an environmentally responsible choice as its longevity reduces the frequency of replacements, thereby minimizing waste. Additionally, steel is one of the most recycled materials globally, and the recycling process is less intensive than producing new materials, further bolstering its eco-friendly credentials. Advancements in technology have also led to innovations in the coating processes, allowing for more efficient methods to galvanize steel which are energy-efficient and produce less waste. This ties back to the growing global emphasis on sustainability in manufacturing and construction sectors, enhancing the authoritative stance of galvanized diamond mesh as a leading material. In conclusion, galvanized diamond mesh remains a staple in various industries due to its unparalleled resilience, flexibility, and range of applications. Its ability to deliver under demanding conditions while providing economic and environmental advantages makes it a preferred choice for professionals worldwide. Its reputation is solidified by the vast number of professionals who continue to vouch for its effectiveness, a testament to its credibility and trustworthiness in the field. As industries evolve and methods advance, galvanized diamond mesh is set to retain its esteemed position as a cornerstone material in both traditional and innovative applications.

The manufacturing process of galvanized diamond mesh speaks volumes of its quality assurance. Each batch undergoes rigorous testing to make sure it meets industry standards. Companies producing high-quality galvanized diamond mesh are known for their stringent quality control policies, ensuring that each piece is capable of withstanding harsh environmental conditions without succumbing to wear and tear. A crucial aspect that underscores the authoritative nature of galvanized diamond mesh is the widespread endorsement by countless engineers and builders. Their continued reliance on this material is a testament to its trustworthiness in critical applications. Many industry professionals provide firsthand accounts of its reliability, often highlighting reduced maintenance costs and longevity as key advantages over alternative materials. Moreover, the sustainability factor cannot be overlooked. The galvanized diamond mesh is an environmentally responsible choice as its longevity reduces the frequency of replacements, thereby minimizing waste. Additionally, steel is one of the most recycled materials globally, and the recycling process is less intensive than producing new materials, further bolstering its eco-friendly credentials. Advancements in technology have also led to innovations in the coating processes, allowing for more efficient methods to galvanize steel which are energy-efficient and produce less waste. This ties back to the growing global emphasis on sustainability in manufacturing and construction sectors, enhancing the authoritative stance of galvanized diamond mesh as a leading material. In conclusion, galvanized diamond mesh remains a staple in various industries due to its unparalleled resilience, flexibility, and range of applications. Its ability to deliver under demanding conditions while providing economic and environmental advantages makes it a preferred choice for professionals worldwide. Its reputation is solidified by the vast number of professionals who continue to vouch for its effectiveness, a testament to its credibility and trustworthiness in the field. As industries evolve and methods advance, galvanized diamond mesh is set to retain its esteemed position as a cornerstone material in both traditional and innovative applications.

Latest news

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

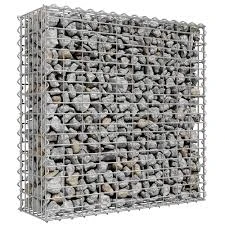

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US