лют . 17, 2025 18:13 Back to list

1 2 x 1 14 gauge welded wire

The 14 gauge welded wire mesh, known for its durability and versatility, is an essential material in various applications ranging from industrial to residential projects. While its robustness is a given, selecting the right specification such as the 1 2 x 1 14 gauge variety demands attention to detail, particularly for efficiency and effectiveness in end uses.

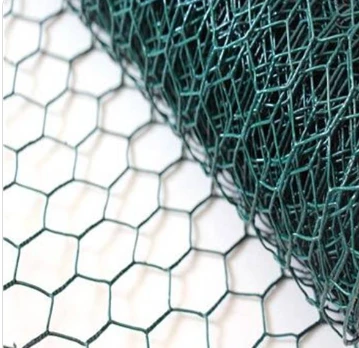

Even artistic expressions benefit from this mesh. Sculptors and designers incorporate it into their works, particularly for frameworks in large-scale installations or as armature for sculptures. The 14 gauge provides enough support to hold substantial weight while also being pliable enough to manipulate into various shapes, enabling unique creative explorations. What about durability? Besides its immediate mechanical properties, the 14 gauge welded wire mesh is often coated with galvanization or PVC. A galvanized mesh resists rust and corrosion, extending its lifespan significantly even in harsher weather conditions. A PVC coating introduces a protective layer that can also add aesthetic value with various color options, allowing the mesh to blend seamlessly into specific design motifs or environments. Purchase and installation require consideration of both quantity and quality. Responsible sourcing from reputable suppliers guarantees compliance with industry standards. Quality certification and material testing are non-negotiable checkpoints that ensure the wire mesh meets safety and performance benchmarks. Installers too, play a crucial role. They must understand tensioning and fastening techniques to maximize the material's inherent properties. While the 1 2 x 1 14 gauge is impressively multifunctional, cost-effectiveness is also a critical consideration. Comparing suppliers based on the material's origin, coating quality, and dimensional consistency can yield savings without compromising on quality. Durability means fewer replacements or repairs over time, thus underscoring its economic advantage in large-scale or prolonged projects. In summary, the 1 2 x 1 14 gauge welded wire serves as a formidable ally across various sectors, including agriculture, construction, security, and arts. Its blend of strength, resilience, and adaptability makes it invaluable. By ensuring adherence to industry best practices in sourcing and installation, users maximize the value derived from this essential material, reinforcing its status as a cornerstone of practical and creative applications.

Even artistic expressions benefit from this mesh. Sculptors and designers incorporate it into their works, particularly for frameworks in large-scale installations or as armature for sculptures. The 14 gauge provides enough support to hold substantial weight while also being pliable enough to manipulate into various shapes, enabling unique creative explorations. What about durability? Besides its immediate mechanical properties, the 14 gauge welded wire mesh is often coated with galvanization or PVC. A galvanized mesh resists rust and corrosion, extending its lifespan significantly even in harsher weather conditions. A PVC coating introduces a protective layer that can also add aesthetic value with various color options, allowing the mesh to blend seamlessly into specific design motifs or environments. Purchase and installation require consideration of both quantity and quality. Responsible sourcing from reputable suppliers guarantees compliance with industry standards. Quality certification and material testing are non-negotiable checkpoints that ensure the wire mesh meets safety and performance benchmarks. Installers too, play a crucial role. They must understand tensioning and fastening techniques to maximize the material's inherent properties. While the 1 2 x 1 14 gauge is impressively multifunctional, cost-effectiveness is also a critical consideration. Comparing suppliers based on the material's origin, coating quality, and dimensional consistency can yield savings without compromising on quality. Durability means fewer replacements or repairs over time, thus underscoring its economic advantage in large-scale or prolonged projects. In summary, the 1 2 x 1 14 gauge welded wire serves as a formidable ally across various sectors, including agriculture, construction, security, and arts. Its blend of strength, resilience, and adaptability makes it invaluable. By ensuring adherence to industry best practices in sourcing and installation, users maximize the value derived from this essential material, reinforcing its status as a cornerstone of practical and creative applications.

Pervious:

Next:

Latest news

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US