Feb . 13, 2025 10:55 Back to list

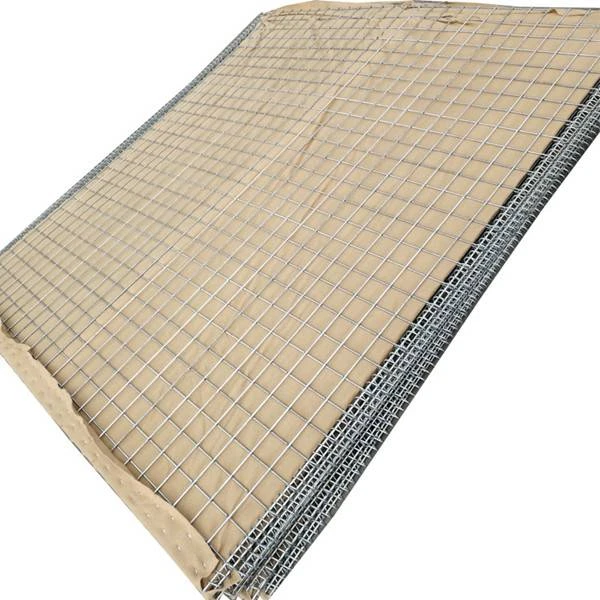

welded wire mesh sheet sizes

The Expertise in Selecting the Right Size Choosing the right welded wire mesh sheet size involves a blend of technical knowledge and practical application insight. Experts in the field understand the balance between minimizing waste and maximizing efficiency. For instance, using larger sheets can reduce installation time and labor costs on large-scale projects, while smaller, more manageable sheets might be more appropriate for intricate or constrained spaces. Further, considerations such as load-bearing requirements, environmental factors like exposure to corrosive elements, and aesthetic preferences can also influence the decision-making process when selecting mesh sizes. Trust and Authority in Sourcing and Certifications Sourcing mesh from reputable manufacturers who adhere to stringent quality standards is paramount. Certification from known organizations such as ISO can serve as a mark of quality assurance and trust. Additionally, manufacturers who offer customization services should be evaluated based on their ability to provide technical support, ensuring that the right specifications are met for unique project demands. Innovation and Future Trends As technology advances, the future of welded wire mesh sheets promises enhanced performance characteristics. Innovations in materials, such as the use of stainless steel or PVC coatings, are expanding the applications and lifespan of these essential products. Smart manufacturing techniques, like CAD software-assisted design, also enable more precise customization, reducing material waste and optimizing supply chains. Conclusion Understanding welded wire mesh sheet sizes is foundational to leveraging their full potential in various applications. Industry professionals must balance engineering basics with emerging trends to choose the right size for specific needs, considering factors from load requirements to local standards. This expertise, coupled with sourcing from trustworthy manufacturers, not only ensures the success of a project but also reinforces the professional's reputation as a knowledgeable and reliable partner in the field.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories