Sep . 02, 2025 05:20 Back to list

Welded Mesh Gabion: Durable, Easy-Install Retaining Walls

Introduction to Welded Mesh Gabions in Modern Infrastructure

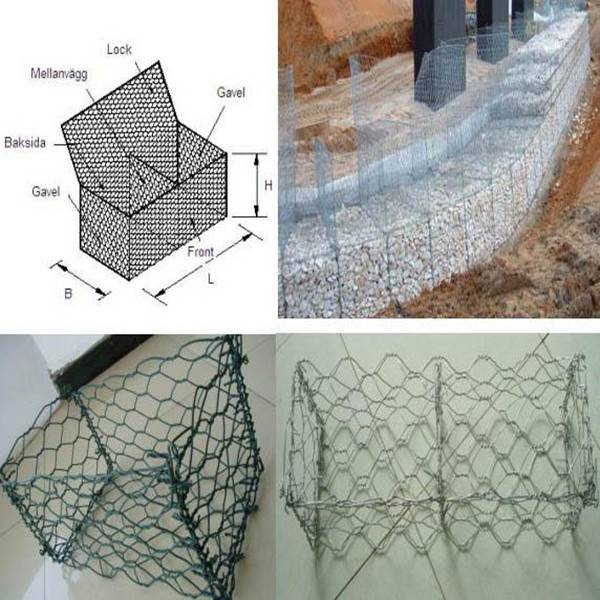

In the demanding landscape of modern civil engineering and environmental management, the welded mesh gabion stands as a cornerstone solution for robust and versatile structural applications. Unlike traditional woven gabions, these units are constructed from rigid, electrically welded steel wire mesh, forming modular baskets that are then filled with inert materials such as rock, concrete, or soil. This design confers superior structural integrity, dimensional stability, and aesthetic appeal, making them indispensable in projects requiring high performance, durability, and ease of installation. From erosion control and retaining walls to architectural facades and flood protection, the adaptability and inherent strength of these systems have positioned them as a preferred choice among engineers and contractors globally. Their ability to integrate seamlessly into diverse environments while offering significant technical advantages underscores their value in sustainable infrastructure development.

Industry Trends and Market Evolution

The market for welded mesh gabion solutions is experiencing dynamic growth, driven by an increasing global emphasis on sustainable infrastructure, climate change resilience, and rapid construction methodologies. Key trends include the integration of advanced coating technologies, such as Galfan (zinc-aluminum alloy) and PVC coatings, which significantly extend the service life of gabions in aggressive environments, including marine and highly acidic soils. There is a growing demand for custom-sized and aesthetically pleasing gabion designs, enabling architects and landscape designers to incorporate these functional structures into visually compelling urban and natural spaces. Furthermore, the adoption of prefabricated, collapsible welded mesh gabion baskets is streamlining logistics and installation processes, reducing both labor costs and project timelines. The shift towards environmentally friendly construction practices also favors gabions due to their use of locally sourced fill materials, reducing carbon footprints associated with material transport. As urban development continues and natural disaster mitigation becomes paramount, the versatility and cost-effectiveness of these systems are driving their expanded application across various sectors.

Global Market Projections for Gabion Solutions

According to recent industry analyses, the global gabion market is projected to reach approximately USD 1.5 billion by 2028, exhibiting a Compound Annual Growth Rate (CAGR) of around 5.5% from 2021 to 2028. This growth is primarily fueled by extensive investments in infrastructure development, rising concerns over soil erosion and landslides, and increased awareness of the environmental benefits offered by gabion structures.

Manufacturing Process Flow of Welded Mesh Gabions

The production of high-quality gabion welded wire mesh involves a meticulously controlled process to ensure maximum strength, durability, and adherence to international standards. Our manufacturing facilities leverage state-of-the-art machinery and rigorous quality control protocols at every stage.

Materials and Fabrication

- High-Tensile Steel Wire: The foundation of our gabions is low-carbon steel wire (typically AISI 1006-1008), selected for its optimal balance of strength and ductility. Wire diameters generally range from 2.5 mm to 6.0 mm, depending on the required structural capacity.

- Wire Drawing: Raw steel rods undergo a cold drawing process to achieve the precise wire diameter and enhance tensile strength, often exceeding 500 N/mm².

- Electric Resistance Welding: Individual wires are precisely cut and then joined at their intersections using advanced electric resistance welding machines. This process ensures a robust, consistent, and square or rectangular mesh opening, preventing deformation under load.

- Corrosion Protection:

- Hot-Dip Galvanization: Post-welding, the mesh panels are typically hot-dip galvanized in accordance with ASTM A641/A974 standards, applying a heavy zinc coating (e.g., 240-300 g/m²) for superior cathodic protection against corrosion.

- Galfan (Zinc-Aluminum) Coating: For enhanced corrosion resistance, especially in marine or highly aggressive environments, a Galfan coating (95% Zinc, 5% Aluminum) is applied. This coating offers up to three times the lifespan of standard galvanization.

- PVC Coating: An additional layer of UV-stabilized PVC (Polyvinyl Chloride) is often extruded over the galvanized or Galfan-coated wire. This provides exceptional resistance to chemical degradation, abrasion, and weathering, extending service life in harsh conditions by decades.

- Panel Fabrication: The welded and coated mesh is then cut and folded into individual panels (front, back, sides, lid, base, and diaphragms) using precision CNC bending machines, ensuring accurate dimensions for easy assembly.

- Quality Control & Testing: Throughout the process, strict quality control measures are implemented. This includes wire tensile strength tests (per ASTM A641), coating adherence tests (per ISO 1461), mesh opening dimension checks, and welding integrity inspections. Final products conform to international standards such as ASTM A974, EN 10223-8, and ISO 9001 quality management systems.

- Packaging: Finished panels are compactly folded flat and bundled for efficient transportation, reducing shipping costs and onsite handling complexities.

Service Life and Target Industries

The service life of a welded mesh gabion is significantly influenced by its coating. Galvanized gabions typically offer a service life of 20-30 years, while Galfan-coated units can exceed 50 years, and PVC-coated gabions are designed for 75+ years, even in challenging environments. Target industries include:

- Civil Engineering: Retaining walls, bridge abutments, noise barriers, road embankments.

- Environmental & Water Management: River training, canal lining, erosion control, flood protection, dam stabilization.

- Landscape Architecture: Decorative walls, garden features, seating, terracing.

- Mining & Energy: Slope stabilization, protective barriers.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of welded mesh gabion baskets is crucial for effective project planning and execution. Our products are engineered to meet stringent performance requirements, ensuring structural integrity and longevity.

Standard Product Specifications Table

| Parameter | Specification | Standard(s) |

|---|---|---|

| Wire Diameter (Mesh) | 3.0 mm - 6.0 mm (typical) | ASTM A641/A974, EN 10223-8 |

| Wire Diameter (Lacing/Bracing) | 2.2 mm - 3.5 mm (typical) | ASTM A641/A974, EN 10223-8 |

| Mesh Opening Size | 50x50 mm, 75x75 mm, 75x100 mm, 100x100 mm | +/- 3% tolerance |

| Tensile Strength of Wire | Min. 500 N/mm² (70,000 psi) | ASTM A641 |

| Zinc Coating Weight | Min. 240-300 g/m² | ASTM A641, ISO 1461 |

| Galfan Coating | Min. 240 g/m² (95% Zn, 5% Al) | ASTM A856/A856M |

| PVC Coating Thickness | Min. 0.5 mm (total diameter increase ~1.0 mm) | ASTM F544, EN 10245-2 |

| Typical Gabion Dimensions (L x W x H) | 1.0-4.0 m x 0.5-1.0 m x 0.5-1.0 m | Customizable |

The structural integrity of gabion welded wire mesh is paramount. Weld shear strength is tested to withstand a minimum of 40% of the ultimate tensile strength of the un-welded wire, a critical factor for resisting hydrostatic and soil pressures. The flexibility of the wire, even after coating, allows for natural settlement and differential movement without compromising the overall structure, distinguishing it from rigid concrete constructions.

Versatile Application Scenarios

The inherent adaptability of the welded mesh gabion makes it suitable for a broad spectrum of engineering and architectural applications. Its modular nature allows for scalable solutions, from small-scale residential landscaping to large-scale civil infrastructure projects.

- Retaining Walls: Essential for stabilizing slopes, preventing landslides, and creating level platforms in challenging terrains. Gabion retaining walls offer a flexible, free-draining solution that can accommodate minor ground movement without structural failure.

- Erosion Control & River Training: Utilized along riverbanks, canal linings, and coastal areas to protect against scour and erosion. The permeable nature dissipates hydraulic energy, minimizing damage from fast-flowing water.

- Channel Linings & Weirs: Provides stable and durable structures for water flow management, ensuring channel integrity and preventing sedimentation.

- Bridge Abutments & Wing Walls: Offers a cost-effective and structurally sound alternative to traditional concrete structures for supporting bridge ends and guiding earthworks.

- Noise Barriers: When filled with specific aggregate, gabions can effectively attenuate sound, making them ideal for highway and railway noise reduction.

- Architectural & Landscaping Features: Beyond their engineering function, welded mesh gabion baskets are increasingly used for aesthetic purposes in urban design, creating distinctive facades, seating, planters, and decorative fences.

- Temporary Flood Protection: Easily deployable and filled on-site, they provide quick and effective barriers against rising water levels in emergency scenarios.

Technical Advantages and Performance Benefits

The adoption of gabion welded wire mesh solutions offers significant technical and environmental advantages over conventional construction methods. These benefits translate directly into long-term cost savings, enhanced project resilience, and sustainable outcomes.

- Structural Rigidity and Stability: The welded construction provides a rigid, uniform structure that resists deformation under static and dynamic loads, making it superior to woven gabions for vertical structures and architectural applications.

- Excellent Drainage Characteristics: Gabion structures are inherently permeable, allowing water to pass through freely. This prevents hydrostatic pressure buildup behind retaining walls, a common cause of failure in solid structures, thus enhancing stability and minimizing the need for complex drainage systems.

- High Corrosion Resistance: Multi-layer protection (heavy galvanization, Galfan, or PVC coating) ensures exceptional longevity, even in harsh, corrosive environments, reducing maintenance requirements and lifecycle costs.

- Environmental Compatibility: Gabions integrate naturally into the landscape. They can be vegetated over time, promoting biodiversity and reducing visual impact. The use of locally sourced fill material minimizes transportation emissions and supports local economies.

- Flexibility and Adaptability: While rigid in structure, gabion walls exhibit a degree of flexibility, allowing them to tolerate minor ground settlement and differential movement without cracking or collapsing, unlike rigid concrete structures.

- Ease and Speed of Installation: Prefabricated flat-packed panels are easily transported and assembled on-site. Once filled with suitable aggregate, they form monolithic structures, significantly reducing installation time and labor costs compared to traditional masonry or concrete.

- Cost-Effectiveness: Lower material and labor costs, coupled with reduced maintenance needs and long service life, make welded mesh gabion solutions a highly economical choice for various infrastructure projects.

- Energy Efficiency: The manufacturing process for the steel wire and coatings is optimized for energy efficiency. Furthermore, their role in preventing erosion and stabilizing landscapes contributes to ecological balance, indirectly supporting energy-saving initiatives in environmental remediation.

Vendor Comparison and Selection Criteria

Selecting the right supplier for welded mesh gabion products is critical to project success. While many vendors exist, discerning buyers in the B2B sector should prioritize several key factors beyond mere price. Our commitment to quality and service sets us apart.

Key Differentiation Points

| Criterion | HardwareInStore Advantages | Typical Competitor Limitations |

|---|---|---|

| Material Quality & Sourcing | Premium low-carbon steel, certified to international standards (e.g., ASTM, EN). Consistent wire diameter and tensile strength. | Varied wire quality, unverified steel sources, inconsistent mechanical properties. |

| Welding Integrity | Advanced electric resistance welding, tested for minimum 40% parent wire tensile strength. Uniform mesh openings. | Inconsistent weld strength, potential for premature weld failure, irregular mesh patterns. |

| Corrosion Protection | Guaranteed heavy galvanization (240-300 g/m²), optional Galfan and UV-stabilized PVC coatings for extended lifespans (50-75+ years). | Thin galvanization (below 200 g/m²), unreliable PVC adherence, limited coating options. |

| Customization & Engineering Support | Full range of custom sizes, coatings, and mesh configurations. Dedicated engineering team for project-specific design and consultation. | Limited standard sizes, reluctance for special orders, minimal technical support. |

| Certifications & Compliance | ISO 9001, ASTM A974, EN 10223-8 certified products. Full traceability of materials. | Lack of verifiable certifications, unknown adherence to international standards. |

Customized Solutions and Design Flexibility

Understanding that every project presents unique challenges, we specialize in providing bespoke welded mesh gabion solutions tailored to specific site conditions, aesthetic requirements, and engineering demands. Our in-house design and engineering teams work collaboratively with clients to optimize gabion dimensions, mesh configurations, wire gauges, and coating types.

Whether it's designing custom welded mesh gabion baskets for intricate architectural features, developing specialized coating systems for extreme marine environments, or engineering large-scale retaining walls with integrated drainage, our capabilities ensure that the final product not only meets but exceeds performance expectations. This collaborative approach ensures cost-effective solutions without compromising on structural integrity or environmental sustainability.

Application Case Studies

Our welded mesh gabion products have been successfully deployed in numerous high-profile projects worldwide, demonstrating their reliability and versatility.

Case Study 1: Coastal Erosion Protection Project, South-East Asia

Challenge: A rapidly eroding coastline threatened critical infrastructure and local communities due to severe monsoon seasons and tidal action. Traditional riprap proved insufficient and unstable. Solution: We supplied thousands of PVC-coated welded mesh gabion baskets, specifically designed for extreme marine environments. These were filled with locally available durable rock and strategically placed to form robust sea walls and groynes. Outcome: The gabion structures successfully stabilized the coastline, resisting storm surges and preventing further erosion. The permeable nature allowed for natural water flow, and the PVC coating ensured a projected service life exceeding 70 years, significantly reducing maintenance costs.

Case Study 2: Urban Road Embankment Stabilization, Europe

Challenge: An urban highway expansion project required the construction of steep, load-bearing embankments adjacent to residential areas, demanding both structural stability and minimal visual impact. Solution: Our Galfan-coated gabion welded wire mesh units were utilized to construct tiered retaining walls. The precise modularity and aesthetic fill (varied local stone) allowed for a clean, modern finish that blended with the urban landscape. The inherent drainage prevented hydrostatic pressure build-up. Outcome: The gabion walls provided exceptional stability for the new road infrastructure, accommodating significant earth loads. The rapid construction significantly reduced traffic disruption, and the aesthetically pleasing design garnered positive feedback from the community.

Frequently Asked Questions (FAQ)

- Q: What is the primary difference between welded mesh gabions and woven mesh gabions?

- A: Welded mesh gabions are made from rigid, electrically welded mesh, providing superior structural integrity, dimensional stability, and a more aesthetically pleasing, rectilinear form. Woven gabions are more flexible and adaptable to minor ground settlement but can deform more easily. Welded gabions are preferred for retaining walls, architectural features, and applications requiring a more precise finish.

- Q: What infill materials are suitable for welded mesh gabions?

- A: The most common infill material is clean, hard, durable, non-frost susceptible rock (e.g., granite, basalt, sandstone) with an average size larger than the mesh opening. Recycled concrete, brick, or even specific types of soil can also be used depending on the application and design requirements.

- Q: How do welded mesh gabions contribute to environmental sustainability?

- A: They are considered eco-friendly due to their use of locally sourced fill materials, reducing transportation emissions. Their permeable nature promotes natural drainage and can support vegetation growth, fostering biodiversity and blending seamlessly with natural landscapes.

- Q: What is the typical lead time for an order of welded mesh gabions?

- A: Standard orders typically have a lead time of 2-4 weeks from order confirmation to shipment, depending on quantity and specific coating requirements. For large-scale or highly customized projects, we will provide a detailed production schedule upon consultation.

- Q: Do you offer warranty on your products?

- A: Yes, all our welded mesh gabion products come with a comprehensive material and coating warranty. Standard galvanized products typically carry a 5-year warranty, Galfan-coated products a 10-year warranty, and PVC-coated products a 20-year warranty against manufacturing defects and premature corrosion under normal operating conditions. Extended warranties are available for specific project requirements.

Customer Support and Logistics

Our commitment extends beyond product delivery. We offer comprehensive customer support, including technical assistance for design and installation, project management consultation, and efficient global logistics. Our experienced team is available to answer inquiries, provide detailed product specifications, and offer solutions tailored to your project's unique demands. We strive for seamless order fulfillment, working with trusted logistics partners to ensure timely and secure delivery to your job site, anywhere in the world.

Authoritative References

- American Society for Testing and Materials (ASTM) International. ASTM A974/A974M-97(2021) Standard Specification for Welded Wire Fabric Gabions and Gabion Mattresses.

- European Committee for Standardization (CEN). EN 10223-8: Steel wire and wire products for fencing and netting - Part 8: Welded mesh gabions.

- International Organization for Standardization (ISO). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods.

- Maccaferri. Gabion Wall Design Guide. Available at: [Relevant Maccaferri Technical Publications - specific URL varies].

- FHWA. Gabion Retaining Walls. Federal Highway Administration Geotechnical Engineering Circular No. 7, 2011.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories