Nov . 14, 2025 07:20 Back to list

Welded Mesh Gabion – Durable, Fast Install, Cost-Effective

Welded Mesh Gabion is a key solution in the manufacturing industry, specifically within Metal product manufacturing industry and Manufacturing of metal wires and metal products. This article explores how HEBEI XINTELI CO.,LTD. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Welded Mesh Gabion Overview

- Benefits & Use Cases of Welded Mesh Gabion in Manufacturing of metal wires and metal products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Welded Mesh Gabion from HEBEI XINTELI CO.,LTD.

Welded Mesh Gabion Overview

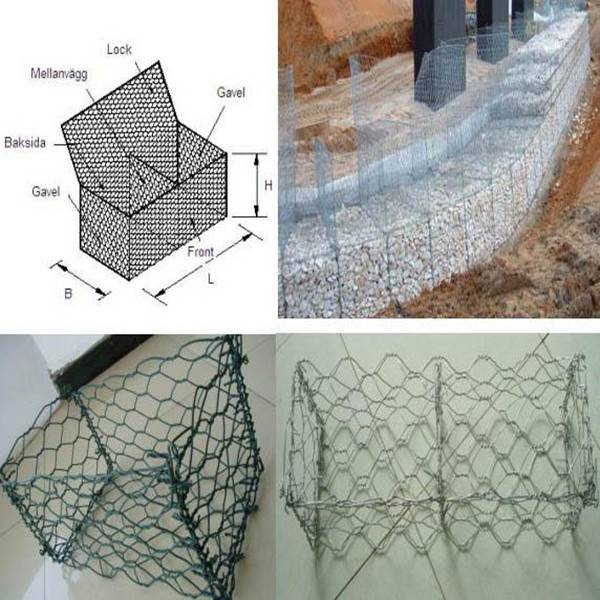

A welded mesh gabion is a rigid, panel-assembled cage made from gabion welded wire mesh that is filled with stone or recycled aggregates to construct retaining walls, river training works, cladding, and noise or security barriers. Unlike woven hexagonal baskets, welded mesh gabion baskets offer superior dimensional accuracy and a clean architectural finish—key for industrial and commercial sites that demand predictable tolerances and fast installation. Typical specifications include low-carbon steel wire in 3.0–6.0 mm diameters, mesh apertures of 50×50 mm, 75×75 mm, or 100×50 mm, and coatings such as heavy zinc (EN 10244-2), Zn-Al (Galfan), and optional PVC/PE for aggressive environments. Common module sizes are 1×1×1 m and 2×1×1 m, supplied flat-packed with corner stiffeners and lacing or spiral binders.

HEBEI XINTELI CO.,LTD. manufactures welded mesh gabions on automated resistance-welding lines to ensure consistent weld strength and panel flatness. Products are engineered to align with widely recognized practices such as ASTM A974 for welded wire gabions and ISO-driven quality systems. For B2B buyers in the Metal product manufacturing industry, the company provides OEM/ODM options—custom mesh sizes, wire diameters, coatings, labeling, and palletization—to fit project specifications and distribution models across infrastructure, mining, and industrial landscaping applications.

Benefits & Use Cases of Welded Mesh Gabion in Manufacturing of metal wires and metal products

In the Manufacturing of metal wires and metal products segment, welded mesh gabion baskets integrate seamlessly into value-added product portfolios: pre-assembled wall modules for EPC contractors, architectural façade cassettes for industrial parks, and channel lining systems for utilities. Their rigidity ensures crisp lines and vertical faces, enabling high-end finishes in factories, logistics centers, rail corridors, and energy sites. For flood control and slope stabilization, the open, permeable gabion welded wire mesh reduces hydrostatic pressure while accommodating plant growth for bioengineering solutions.

Competitive advantages include rapid installation (panel alignment and corner stiffeners speed up assembly), predictable geometry, and easier quality control versus woven alternatives. With Galfan or PVC over-galvanized options, service life is extended in coastal or de-icing salt environments. HEBEI XINTELI CO.,LTD. brings sector expertise with precision welding, tight dimensional control, and robust logistics—container optimization, flat-pack export packaging, and clear assembly guides. That combination helps distributors, contractors, and OEMs shorten lead times, standardize SKUs, and deliver repeatable outcomes on industrial-scale programs.

Cost, Maintenance & User Experience

Total cost of ownership favors welded mesh gabions through labor savings and long service life. Panelized assemblies are typically 20–35% faster to install than laced woven baskets, especially on straight walls and architectural applications. Using locally available stone fill lowers transport cost and embodied carbon. With heavy zinc or Zn-Al coatings—and optional PVC jacketing—operators gain enhanced corrosion resistance, reducing lifecycle spend on replacements. For industrial estates and infrastructure corridors, the minimal maintenance requirement (periodic visual checks for settlement and vegetation management) translates to predictable OPEX.

Feedback from contractors and site managers in the Metal product manufacturing industry highlights ease of assembly, consistent panel flatness, and fewer reworks. Flat-packed delivery optimizes warehouse space, and clear labeling supports fast picking for multi-phase projects. Many B2B buyers report accelerated project handover due to the system’s rigidity and clean aesthetics, which often eliminates additional cladding. Overall ROI is driven by shorter installation windows, reduced skilled labor demand, and durable performance under heavy industrial use.

Sustainability & Market Trends in manufacturing

Sustainability priorities are reshaping metal product manufacturing and project specifications. Welded mesh gabions support green infrastructure by using inert, often local stone fill, enabling permeability and habitat creation while minimizing concrete use. Steel’s recyclability and the option for high-performance coatings (which extend service life and reduce replacement frequency) align with lifecycle and circularity goals. Projects can also reference recognized frameworks where applicable, and the material transparency trend is encouraging EPDs and coating compliance with REACH and RoHS considerations.

Market trends point to resilient flood defenses, low-maintenance industrial landscaping, and architecturally exposed retaining systems. Digitalization—BIM objects, standardized detailing, and pre-engineered modules—further accelerates adoption. HEBEI XINTELI CO.,LTD. positions itself as forward-thinking and eco-conscious through controlled galvanizing processes, coating selections tailored to environment categories, and a quality system aimed at minimizing waste and rework. For B2B decision makers, this means reliable compliance, fewer site issues, and a partner that understands both performance and sustainability benchmarks.

Conclusion on Welded Mesh Gabion from HEBEI XINTELI CO.,LTD.

For industrial sites, infrastructure, and OEM solutions, welded mesh gabion baskets deliver structural reliability, speed of build, and a professional finish. As a specialist in the Manufacturing of metal wires and metal products, HEBEI XINTELI CO.,LTD. supplies robust, customizable gabion welded wire mesh engineered for long-term value and simplified logistics. Backed by rigorous manufacturing controls and practical packaging, our solutions help B2B buyers reduce installation time and lifecycle costs. Contact us: email: ganxuezhong@hebeiminmetals.com — Visit our website: https://www.hardwareinstore.com

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories