Sep . 15, 2025 10:20 Back to list

Premium PVC Coated Wire Mesh for Sale - Durable & Long-Lasting

Strategic Investment: Understanding PVC Coated Wire Mesh for Industrial Applications

In diverse industrial sectors, the demand for resilient, cost-effective, and long-lasting fencing and containment solutions is paramount. Among these, pvc coated wire mesh for sale stands out as a superior choice. This comprehensive analysis delves into its technical intricacies, market dynamics, and strategic advantages for B2B decision-makers and engineering professionals. We will explore the manufacturing process, key specifications, critical applications, and the overall value proposition that makes this material an indispensable asset across various industries.

Current Industry Trends and Market Outlook

The global market for protective barriers and enclosure systems is experiencing robust growth, driven by increasing infrastructure development, stringent safety regulations, and the need for durable, low-maintenance materials. Within this landscape, pvc coated wire mesh has emerged as a preferred solution due to its exceptional corrosion resistance, extended service life, and aesthetic versatility. Market analyses project a sustained compound annual growth rate (CAGR) for coated wire products, propelled by demand from the construction, agriculture, petrochemical, and security sectors. The emphasis on sustainable, environmentally compliant manufacturing processes is also a key trend, favoring manufacturers who adhere to international standards for PVC coating application and material sourcing.

Precision Engineering: The Manufacturing Process of PVC Coated Wire Mesh

The production of pvc coated welded wire mesh involves a meticulously controlled multi-stage process, designed to imbue the final product with superior strength, durability, and corrosion resistance. Understanding these stages is crucial for appreciating the product's quality and performance characteristics.

Detailed Process Flow:

- Wire Drawing & Straightening: High-quality steel wire rods are drawn through dies to achieve precise diameters, followed by straightening and cutting to specified lengths. The base material is typically low carbon steel or galvanized steel, offering foundational tensile strength.

- Welding: The cut wires are then precisely positioned and joined at intersections using advanced resistance welding technology. This creates a robust, uniform mesh structure. For pvc welded wire mesh, the welding process is critical for structural integrity before coating.

- Pre-treatment: The welded mesh undergoes a thorough cleaning and degreasing process, often involving acid pickling and rinsing. This step is vital to ensure optimal adhesion of the PVC coating. Some manufacturers also apply a primer layer for enhanced bonding.

- PVC Coating Application: This is the defining stage. The pre-treated mesh is typically submerged in a fluidized bed of PVC powder or coated using an electrostatic spray method. The mesh is then heated to specific temperatures, causing the PVC powder to melt and uniformly fuse onto the wire surface, forming a thick, protective layer. This process is crucial for the performance of pvc coated wire mesh for sale.

- Curing and Cooling: After coating, the mesh is cured at elevated temperatures to ensure complete polymerization and adhesion of the PVC layer. Subsequently, it is carefully cooled to ambient temperature, solidifying the protective coating.

- Quality Control & Testing: Throughout the process, stringent quality control measures are implemented. This includes visual inspection for coating uniformity, adhesion tests (e.g., cross-hatch adhesion), thickness measurements, and bend tests. Finished products are often tested against international standards such as ISO 9001 for manufacturing quality and ASTM standards for material properties and corrosion resistance, ensuring a service life exceeding 15-20 years under normal conditions.

Target industries benefiting from this robust material include petrochemical, metallurgy, water supply & drainage, agriculture, and construction. The manufacturing integrity ensures advantages such as enhanced corrosion resistance and significant energy savings in maintenance costs over the product's lifespan.

Technical Specifications and Unrivaled Advantages

The technical prowess of PVC coated wire mesh lies in its synergistic combination of a strong steel core and a resilient polymer coating. This combination delivers a product engineered for demanding environments.

Key Technical Parameters:

| Parameter | Specification Range | Description |

|---|---|---|

| Material Core | Low Carbon Steel (Q195/Q235), Galvanized Steel (Hot-dip/Electro) | Provides structural strength and formability. Galvanization offers initial corrosion protection. |

| Wire Diameter (Core) | 0.5 mm - 4.0 mm (0.02 - 0.16 inches) | Determines the mesh's rigidity and load-bearing capacity. |

| Mesh Opening | 6.35 mm x 6.35 mm to 100 mm x 100 mm (1/4" to 4") | Versatile range for various containment and barrier needs. |

| PVC Coating Thickness | 0.4 mm - 1.0 mm (on each side) | Critical for corrosion resistance, UV stability, and abrasion protection. |

| Tensile Strength | 350-550 N/mm² (for steel core) | Indicates the force required to break the wire. |

| Corrosion Resistance | Excellent (Salt Spray Test > 1000 hours) | Primary advantage, ideal for harsh outdoor and chemical environments. |

| UV Resistance | High (UV stabilizers in PVC) | Prevents degradation from prolonged sun exposure, extending outdoor service life. |

Technical Advantages:

- Superior Corrosion Resistance: The thick PVC layer acts as an impermeable barrier against moisture, chemicals, and corrosive agents, significantly outperforming un-coated or simply galvanized meshes in aggressive environments. This is a critical advantage for pvc coated wire mesh for sale in coastal or industrial settings.

- Extended Service Life: With its enhanced protection, PVC coated mesh offers a service life typically 2-3 times longer than standard galvanized mesh, reducing replacement costs and maintenance cycles. This translates to substantial long-term savings for B2B clients.

- Aesthetic Appeal: Available in a variety of colors (most commonly green, black, grey), the PVC coating provides an attractive finish that can blend seamlessly with natural or urban landscapes, enhancing the overall project aesthetics.

- Low Maintenance: The durable PVC surface is easy to clean and requires minimal upkeep, contributing to lower operational expenditures over its lifespan.

- Enhanced Safety: The smooth PVC coating eliminates sharp edges, making the mesh safer to handle and install, reducing potential injury risks for personnel.

- UV Stability: Integrated UV stabilizers in the PVC compound prevent color fading and material degradation due to prolonged exposure to sunlight, ensuring long-term performance in outdoor applications.

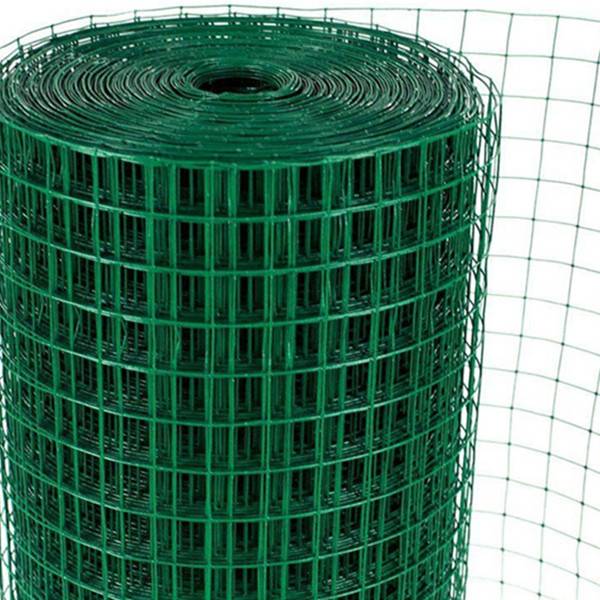

Image 1: Close-up of PVC Coated Welded Wire Mesh demonstrating robust coating.

Versatile Application Scenarios Across Key Industries

The adaptability and durability of pvc coated wire mesh make it suitable for an extensive range of applications, providing reliable solutions across diverse industrial and commercial sectors.

Typical Application Scenarios:

- Perimeter Fencing and Security: Widely used for residential, commercial, and industrial property boundaries, including airports, military bases, and correctional facilities, offering a secure, long-lasting barrier. The availability of pvc coated welded wire mesh rolls facilitates quick and efficient installation for large perimeters.

- Agricultural and Animal Enclosures: Ideal for livestock fencing, poultry coops, pet enclosures, and garden protection. The non-toxic PVC coating is safe for animals, and its resistance to weathering ensures longevity in outdoor environments.

- Industrial Guarding: Used for machine guarding, warehouse partitioning, and safety enclosures within manufacturing plants to protect personnel from moving machinery or hazardous areas.

- Construction and Infrastructure: Utilized in concrete reinforcement (light-duty), gabion mesh for erosion control, retaining walls, and temporary fencing for construction sites. Its corrosion resistance is critical in humid or saline environments.

- Public Works and Landscaping: Employed for park fencing, public amenity enclosures, trail demarcation, and decorative landscaping elements. The variety of colors allows for seamless integration into various designs.

- Marine and Coastal Applications: While not primary, select variants can be used in splash zones or areas requiring higher resistance to saltwater, where the PVC coating offers a superior barrier compared to standard galvanized options.

Image 2: PVC Coated Welded Wire Mesh installed for perimeter security.

Vendor Comparison and Customized Solutions

Selecting the right supplier for pvc coated wire mesh for sale is a critical decision that impacts project longevity, cost-efficiency, and overall reliability. Factors such as adherence to international standards, material quality, coating thickness, and customization capabilities differentiate leading manufacturers.

Key Differentiators in Vendor Selection:

- Coating Quality & Adhesion: Premium vendors ensure a uniform, thick PVC coating with superior adhesion, preventing delamination and extending protection. Inferior coatings can chip or peel, compromising the steel core.

- Base Material Quality: Reputable suppliers use high-grade galvanized steel wire as the substrate, providing an additional layer of corrosion resistance even if the PVC coating is compromised.

- Welding Strength: Strong, consistent welds are paramount for structural integrity, preventing mesh separation under stress.

- Certifications: Look for ISO 9001, ASTM, or equivalent certifications demonstrating adherence to rigorous quality management systems and product standards.

Comparison: Standard vs. Premium PVC Coated Wire Mesh

| Feature | Standard PVC Coated Mesh | Premium PVC Coated Mesh |

|---|---|---|

| Base Wire | Electro-galvanized or plain steel | Hot-dip galvanized steel (enhanced rust prevention) |

| PVC Coating Thickness | 0.3 - 0.5 mm | 0.6 - 1.0 mm (superior protection) |

| UV Resistance | Moderate (basic stabilizers) | High (advanced UV inhibitors) |

| Adhesion Quality | Good | Excellent (pre-treatment + primer layer) |

| Expected Service Life | 5-10 years | 15-20+ years |

| Warranty | Limited (e.g., 1-5 years) | Extended (e.g., 10-15 years) |

Customized Solutions: Tailoring to Specific Project Needs

Leading providers of pvc coated wire mesh offer extensive customization options to meet unique project requirements. This includes:

- Variable Mesh Sizes & Wire Gauges: Tailored to specific security levels, animal containment, or filtration needs.

- Custom Colors: Beyond standard green and black, special color matching can be provided for architectural integration or branding.

- Roll or Panel Formats: Whether you require pvc coated welded wire mesh rolls for extensive linear fencing or pre-cut panels for specific installations, manufacturers can accommodate.

- Enhanced Coatings: For extremely aggressive chemical environments, specialized PVC compounds with added chemical resistance can be formulated.

Image 3: Diverse applications of PVC Coated Welded Wire Mesh.

Real-World Impact: Application Case Studies and Client Success

The proven performance of pvc coated wire mesh for sale is best illustrated through successful deployments in challenging environments, showcasing its durability and long-term value.

Case Study 1: Coastal Infrastructure Project

A major municipal authority undertaking a coastal promenade development required robust fencing that could withstand harsh saline air, high humidity, and occasional direct saltwater exposure. Traditional galvanized mesh experienced rapid degradation. By implementing a custom-fabricated pvc coated wire mesh system with a 1.0mm thick UV-stabilized PVC layer over hot-dip galvanized steel, the project achieved a significantly extended lifespan. After 10 years, the mesh showed no signs of rust or coating delamination, reducing maintenance costs by an estimated 70% compared to previous solutions. Customer feedback emphasized the aesthetic integration and minimal upkeep.

Case Study 2: Industrial Chemical Plant Security

A leading chemical manufacturing facility needed secure perimeter fencing that could resist corrosive fumes and incidental chemical splashes. Standard fencing materials failed prematurely. The solution involved utilizing a specialized pvc coated welded wire mesh with enhanced chemical resistance properties. The mesh not only provided the necessary physical barrier but also maintained its structural and aesthetic integrity in an environment where other metals quickly corroded, proving its reliability and contributing to worker safety.

Case Study 3: Large-Scale Agricultural Enclosures

An expansive agricultural enterprise, operating commercial poultry farms, required thousands of meters of fencing for animal containment and predator exclusion. The chosen solution was large quantities of pvc coated welded wire mesh rolls, specifically designed for agricultural applications. The mesh offered optimal ventilation, durability against animal impacts, and resistance to common agricultural chemicals and weather elements. The green PVC finish blended well with the rural landscape, and the long service life minimized disruption from fence repairs.

Commitment to Quality: , Trustworthiness & Support

Our dedication to providing high-quality pvc coated wire mesh is underpinned by stringent quality assurance protocols, industry certifications, and a steadfast commitment to customer satisfaction.

Certifications and Authoritative References:

- ISO 9001:2015 Certified Manufacturing: Our production facilities adhere to internationally recognized quality management system standards, ensuring consistent product quality from raw material to finished goods.

- ASTM Compliance: Products meet or exceed relevant ASTM (American Society for Testing and Materials) standards for wire mesh and coating properties, guaranteeing performance and material integrity.

- Environmental Standards: Our PVC formulations are lead-free and conform to REACH and RoHS directives, reflecting a commitment to environmental responsibility.

Image 4: Quality assurance team conducting tests on PVC Coated Welded Wire Mesh.

Frequently Asked Questions (FAQ):

Q1: What is the typical lead time for large orders of PVC coated wire mesh?

A1: Standard orders for pvc coated wire mesh for sale are typically processed and shipped within 2-4 weeks, depending on volume and current production schedules. Custom orders may require an additional 1-2 weeks for specialized fabrication and coating processes. Expedited options are available upon request.

Q2: What is the warranty period for your PVC coated wire mesh products?

A2: We offer a comprehensive 10 to 15-year limited warranty against manufacturing defects and significant corrosion under normal usage conditions, contingent on product type and application. Specific warranty details are provided with each quotation.

Q3: Can your PVC coated wire mesh withstand extreme temperatures?

A3: Our PVC coating maintains its integrity and protective properties within a broad temperature range, typically from -30°C to +70°C. For applications beyond this range, specialized coatings can be discussed.

Q4: Do you offer installation support or guidance?

A4: While we primarily supply the material, our technical support team provides detailed installation guidelines and best practices. For large-scale projects, we can also recommend certified installation partners in various regions.

Lead Time, Fulfillment & Customer Support:

We maintain robust inventory levels for standard pvc coated wire mesh rolls and sizes, ensuring prompt fulfillment. Our logistics team is adept at managing both domestic and international shipments, providing comprehensive tracking and delivery updates. Our dedicated customer support team is available during business hours to address technical queries, provide project quotations, and offer after-sales assistance. We believe in building long-term partnerships through reliable products and responsive service.

Image 5: Rolls of PVC Coated Welded Wire Mesh ready for shipment.

Conclusion: A Strategic Choice for Durable Protection

The strategic advantages of pvc coated wire mesh extend beyond mere initial cost. Its superior corrosion resistance, extended lifespan, minimal maintenance requirements, and aesthetic versatility offer a compelling value proposition for any B2B entity seeking reliable and enduring barrier or containment solutions. By understanding its meticulous manufacturing process, diverse technical specifications, and broad application potential, decision-makers can confidently invest in a product that delivers both performance and substantial long-term savings.

References

- American Society for Testing and Materials (ASTM) Standards for Wire Mesh and Coatings.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- Wire Mesh Manufacturers' Association (WMMA) Technical Specifications for Welded Wire Mesh.

- Polyvinyl Chloride (PVC) Industry Association Guidelines for Coating Applications.

- National Association of Corrosion Engineers (NACE) International Publications on Protective Coatings.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories