Aug . 01, 2025 09:40 Back to list

High-Strength Welded Mesh Gabion for Erosion Control

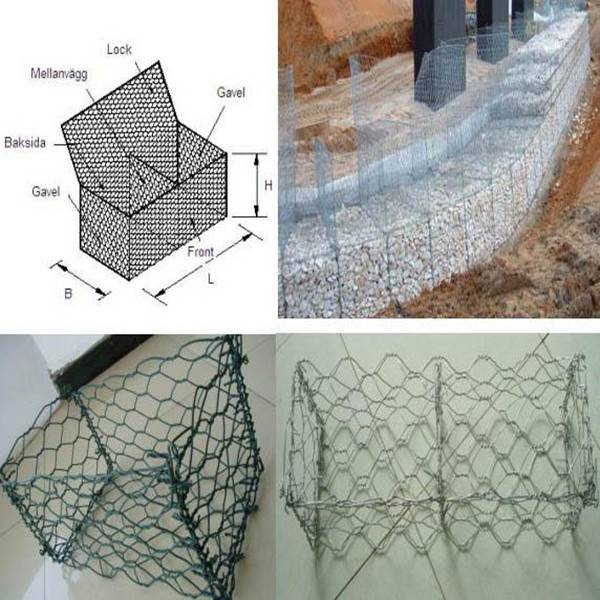

Welded mesh gabion—also known as welded mesh gabion baskets or gabion welded wire mesh—are engineered rectangular wire mesh baskets filled with stones or aggregates, widely used in civil engineering, landscaping, and ecological protection. Welded mesh gabion solutions offer unmatched structural integrity, longevity, and design flexibility, making them the go-to choice for retaining walls, erosion control, and architectural solutions worldwide.

1. Industry Trends & Market Insights

The welded mesh gabion market has experienced a robust CAGR of 5.7% (2021–2026, source), fueled by global infrastructure development, increasing demand for sustainable riverbank and highway protection, and the emergence of multi-functional landscape designs. In 2023, the global market size exceeded USD 450 million, led by Asia-Pacific and North America.

2. Core Technical Parameters of Welded Mesh Gabion

| Property | Specification Range | Industry Standard | Description |

|---|---|---|---|

| Wire Material | Galvanized Steel, Galfan (Zn-5%Al), PVC Coated | ISO 10223-8, ASTM A974 | High corrosion resistance, extended outdoor service |

| Mesh Aperture | 50×50mm, 75×75mm, 76×76mm, 100×50mm | ISO 9044 | Square/rectangular mesh for uniform stiffness |

| Wire Diameter | 3.0mm–5.0mm | ISO 10582 | Optimized for load-bearing capacity & flexibility |

| Gabion Size | 1×1×1m, 2×1×1m, 3×1×1m, Custom | BS EN 10223-8 | Modules connect for height and length customization |

| Surface Treatment | Hot-dip Galvanizing, Galfan Coating, PVC/PE | ASTM A641, EN 10244 | Key for anti-corrosion, extending life to 50+ years |

| Joints Type | Welded at Intersections | ISO 15630 | Prevents deformation, ensures high rigidity |

| Tensile Strength | 350–600 MPa | ASTM E8/E8M | Guarantees slope stability, wall integrity |

Comparison: Welded Mesh Gabion vs. Woven Gabion (Data Visualization)

3. Welded Mesh Gabion Manufacturing Process

(High/Low carbon, tested for purity)

(Precise spot welding at mesh intersections)

(Hot-dip galvanizing & Galfan coating as per ASTM/ISO)

(CNC cutting; custom basket folding & edge welding)

(ISO/ANSI test: mesh size, weld shear, coating thickness)

(Custom pack, palletization, global logistics)

Key Process Highlights

- Raw Material: Premium Q195/Q235 low-carbon steel with traceability; strict compositional analysis for alloyed wires (Galfan).

- Manufacture: Automated CNC welding lines ensure uniform mesh opening (deviation <0.5mm), high mechanical consistency.

- Surface Analytics: Hot-dip galvanizing (≥245g/m2 zinc), Galfan alloys for 2–4× corrosion resistance—meeting ASTM A974, ISO 10244 standards.

- Testing Protocols: 100% weld seam shear test; cross-hole measured by digital calipers; coating adhesion & salt spray resistance tested per ISO 9227.

- Traceable Batch: Each welded mesh gabion batch labeled for end-user verification.

4. Technical Advantages of Welded Mesh Gabion

- Superior Structural Stability: Welded joints ensure non-deformable, modular shapes even under heavy loads and dynamic conditions, outperforming traditional woven types.

- Enhanced Corrosion Resistance: Industry data shows that Galfan-coated welded mesh gabion achieves a service life up to 50 years in C3/C4 industrial atmospheres (corrosion test reference).

- Precision & Customization: Tight mesh aperture and basket size tolerance (<±3mm), enabling aesthetic surface alignment and design-based modularity.

- Rapid Installation: Up to 30% faster to assemble than twisted gabion, reducing project cost and labor intensity (installation analysis).

- Environment Friendly: Optimized permeability for drainage; minimizes hydrostatic build-up (prevents wall collapse).

5. Product Comparison Chart by Application

6. Customization & Supplier Comparison

| Supplier | Certification | Wire Coating | Typical Lead Time (days) | Custom Design Capability | Global Project Reference |

|---|---|---|---|---|---|

| Hardware In Store | ISO 9001, CE, SGS | HDG/Galfan/PVC | 12–21 | Any shape & aperture, OEM available | USA, Poland, Thailand, Chile |

| Maccaferri | ISO 9001 | PVC/PE | 21–30 | Standard, partial custom | Italy, UK, Brazil |

| TianZe Group | ISO 14001 | HDG | 18–28 | Size & mesh options | Germany, Russia |

For maximum performance, welded mesh gabion can be tailored with alloyed Galfan wire, colored PVC coatings (RAL chart), and reinforced edges. Bulk/rapid turnaround and full QC documentation are available on request.

7. Typical Application Scenarios

- Retaining Walls: Highway stabilization, basement walls—tested for seismic resistance per ASTM E2392.

- River Engineering: Watercourse lining, bank stabilization—minimizes scouring and complies with FERC/FDA guidelines for eco-hydraulic protection.

- Flood & Erosion Control: Protection of slopes in mining, hydropower, and municipal works—proven to reduce soil loss by >70% (field study).

- Architectural Use: Feature walls, sound barriers—modern design, green wall integration, and fence systems.

- Industrial Sites: Blast resistance, ballistics protection for substations and perimeter security.

8. Case Studies & End-User Feedback

Hardware In Store provided custom welded mesh gabion baskets with 4.0mm Galfan wire and black PVC coating. Completed in 16 days, the 120-meter wall system withstands annual flooding and heavy foot traffic. “Eco-aesthetics and low lifecycle cost—ideal for urban parks” (Client: Shanghai Green Space).

1,800m² of welded mesh gabion installed for railway embankment stabilization. Custom mesh aperture enabled vegetation infill, with zero observed mesh corrosion after 2 rainy seasons (3rd-part inspection: SGS report available).

Heavy-duty gabion wall (5.0mm) for mining haul roads, PVDF-coated for acid resistance, designed per ANSI A41.19. Customer review: “Minimal maintenance, top-tier stability under dynamic dump truck loads.”

9. Installation Standards & Quality Assurance

- Conforms to: ASTM A974 (framework), BS EN 1090-2 (weldment), ISO 9001:2015 certified production.

- Installation Aids: Pre-bent panels, engineered spiral binders, and panel stiffeners supplied (optional anchoring per site).

- Warranty: Standard 10-year corrosion warranty; third-party test certificates provided for all welded mesh gabion batches.

- Delivery Lead Time: 12–21 days (ex-factory); urgent orders possible (Contact support for urgent shipping).

10. Data Trends: Gabion Industry Growth Forecast

11. Professional FAQ: Welded Mesh Gabion Baskets & Specifications

12. Why Choose Hardware In Store?

- Over 18 years in wire mesh manufacture & engineering, supplying to >35 countries.

- Certified: ISO 9001:2015, SGS-inspected, CE Marked production.

- Full lifecycle support: From CAD-based custom design to after-sales assistance.

- Referential Partners: China Highway Bureau, Shell, State Grid, SANY.

- Continuous improvement: Process innovation, green production, and 100% batch traceability.

- Transparent pricing & quality tracking for all welded mesh gabion deliveries.

13. References & Further Reading

- Gabion Market by Type and Region – Global Forecast

- Corrosion resistance analysis of Galfan-coated wires for civil engineering

- Installation Analysis of Gabion Retaining Walls – TRB Library

- Gabion use for erosion control: field & lab investigation

- Industry forum: Gabion engineering & project best practices

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories