Feb . 14, 2025 23:48 Back to list

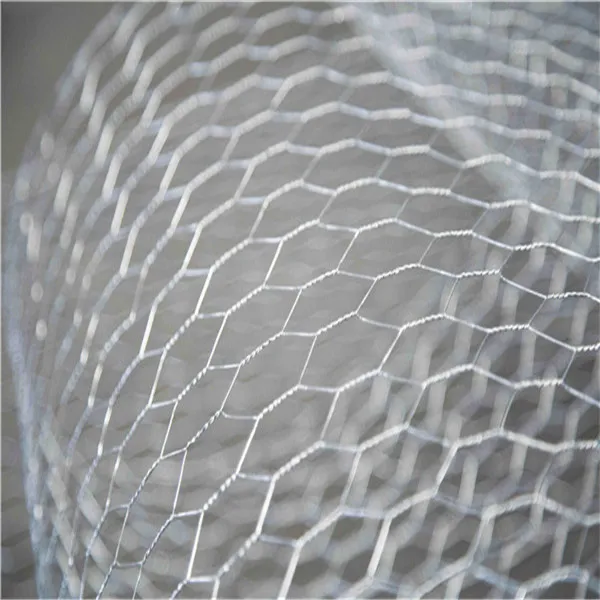

galvanized wire netting

Trust is a fundamental factor when choosing a supplier of galvanized wire netting. Products should comply with industry standards, a critical consideration for projects where safety cannot be compromised. Suppliers must provide certification that guarantees the quality and durability of their offerings. Customer reviews and case studies can also serve as valuable resources in assessing a supplier’s trustworthiness. A reputable supplier will not only ensure a high-quality product but will also offer post-purchase support, guiding clients on installation and maintenance to maximize the netting’s lifespan. Furthermore, many end-users have shared experiences highlighting the cost-effectiveness of galvanized wire netting. While the initial investment might seem higher compared to non-galvanized options, the reduced need for frequent replacements or repairs underscores its long-term value. The upfront cost is mitigated by the peace of mind that comes from knowing the material will perform reliably over extended periods. The environmental impact is another consideration where galvanized wire netting excels. The zinc coating used in galvanization is not only critical for longevity but is also recyclable, aligning with sustainable practices. Choosing galvanized products supports sustainability goals, which can be particularly appealing to organizations striving to reduce their carbon footprint. In conclusion, galvanized wire netting’s combination of durability, versatility, and safety makes it a top-tier choice across various sectors. Its ability to withstand environmental challenges while providing a secure and adaptable solution is unmatched. Navigating the options available requires expertise and a commitment to quality, but the effort ensures that whatever your need—whether securing livestock, reinforcing structures, or ensuring personal safety—galvanized wire netting serves as a trustworthy ally. When quality, reliability, and environmental responsibility are at the forefront, galvanized wire netting emerges not just as a material, but as an essential component in delivering results that stand the test of time.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories