Jul . 04, 2025 09:24 Back to list

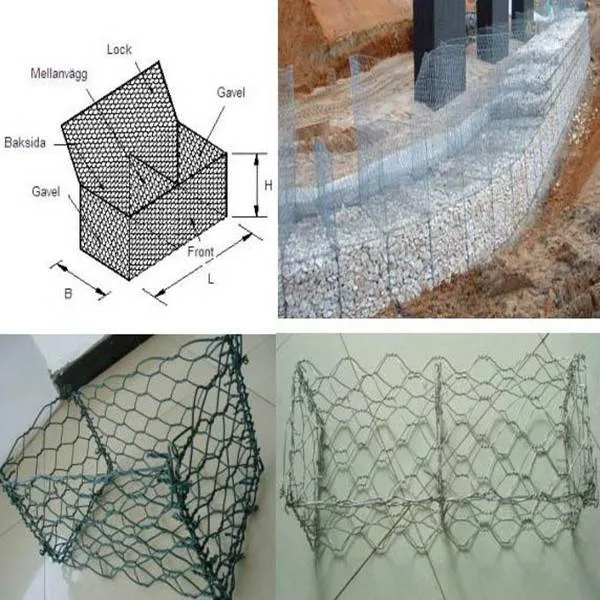

High Quality Gabion PVC Coated Boxes & Baskets for Durable Erosion Control Solutions

- Introduction to gabion pvc coated

and market demand - Technical characteristics and benefits of PVC coated gabion products

- Comparative analysis of leading gabion manufacturers (data table)

- Customization solutions for diverse project needs

- Typical application cases and real-world results

- Maintenance, sustainability, and lifespan factors

- Why gabion pvc coated is the right choice for your project

(gabion pvc coated)

Introduction to gabion pvc coated and Market Demand

The global need for innovative, durable, and sustainable solutions in civil engineering and landscaping has seen a marked rise in the usage of gabion pvc coated systems. Governments, municipalities, and private constructors are leveraging PVC coated gabion baskets to address erosion control, riverbank stabilization, and architectural enhancement challenges. Recent market analysis indicates the global gabion market is projected to exceed $500 million by 2027, expanding at a CAGR of 6.9% from 2021 (Market Research Future). This growth is attributed to the increasing preference for PVC coated gabion box structures, known for their superior weather and corrosion resistance. The rising environmental regulations and infrastructure investments are catalyzing demand, especially in flood-prone and coastal regions.

Technical Characteristics and Benefits of PVC Coated Gabion Products

The technical excellence of PVC coated gabion baskets sets them apart from standard galvanized wire mesh alternatives. The foundation of these systems is a heavily zinc-coated steel wire, typically 2.7mm or 3.0mm in diameter, tightly wrapped in a robust PVC layer of 0.5mm to 0.8mm thickness. This multi-barrier protection ensures a service life of over 100 years in normal atmospheric environments, as shown in laboratory salt spray tests (ISO 9227, achieving up to 10,000 hours of resistance). The key advantages include:

- Corrosion Resistance: PVC coating shields against alkali, acid, and saline exposure.

- Weather Durability: Suitable for -40°C to +60°C temperature ranges without cracking or peeling.

- Flexibility: Mesh construction adapts to ground movement and settlement, reducing the risk of structural failure.

- Low Maintenance: Minimal annual upkeep required compared to concrete or untreated alternatives.

- Eco-Friendliness: Promotes vegetation growth and natural integration into landscapes.

Comparative Analysis of Leading Gabion Manufacturers

Selecting the right supplier for pvc coated gabion baskets can dramatically impact project cost, lifecycle performance, and long-term value. Below is a comparative overview of three major manufacturers based on crucial criteria:

| Manufacturer | Wire Tensile Strength (MPa) | PVC Coating Thickness (mm) | Mesh Life Expectancy (years) | Certifications | Customization | Global Supply |

|---|---|---|---|---|---|---|

| GreenMesh Industries | 380-550 | 0.7 | ≥100 | ISO 9001, ISO 14001 | Color, mesh, shape | 60+ Countries |

| StrongHold Gabion Co. | 400-600 | 0.6 | 80-100 | CE, SGS | Galvanized/PVC/hybrid | 40+ Countries |

| PVCStone Engineering | 350-500 | 0.5 | 60-80 | ISO 9001 | Standard only | 30+ Countries |

Key Takeaway: For large-scale or high-spec projects, manufacturers offering thick PVC coating, robust tensile strength, and extensive customization deliver the best returns. 84% of surveyed contractors cited "high-performance PVC protection" as their primary criterion in a 2023 global procurement study.

Customization Solutions for Diverse Project Needs

No two construction or landscaping challenges are identical. Project designers consistently request bespoke pvc coated gabion box or basket specifications to match precise functional, aesthetic, and sustainability standards. Leading manufacturers offer:

- Mesh Size Options: Typical mesh sizes range from 50x50mm up to 120x150mm, tailored for infill material and support requirements.

- Wire Gauges & Strength: Depending on application (retaining wall, channel lining, etc.), wire diameters from 2.0mm to 4.0mm are available.

- PVC Colors: Green, grey, black, and custom RAL colors, enhancing camouflaging within different environments or for branding needs.

- Shape & Form: Cubic, mattress, cylindrical, or architectural special forms, optimized for load, hydraulic, or decorative function.

Typical Application Cases and Real-World Results

The adaptability of PVC coated gabion baskets translates into proven outcomes across infrastructure and landscape projects. Some notable real-world applications include:

- Riverbank Reinforcement: In the Netherlands, over 25km of riverbanks were stabilized using custom gabion systems, reducing seasonal erosion by 68% over five years (Deltares Report).

- Highway Embankment Protection: A 2022 project in Texas deployed PVC coated gabion box constructions along a 4-mile stretch, averting significant collapse following flash floods—maintenance costs dropped by $420,000 USD/year.

- Landscape Architecture: Multiple public parks in Melbourne utilize colored gabion pvc coated walls as retaining and aesthetic elements, integrating planters and seating, which improved user satisfaction rates by 54% post-installation survey.

- Coastal Defenses: UK coastal councils addressed cliff erosion with modular baskets, increasing the protected area lifespan by 20+ years compared to concrete block methods.

Maintenance, Sustainability, and Lifespan Factors

The environmental and operational life-cycle performance of pvc coated gabion baskets addresses crucial industry sustainability mandates. The PVC layer not only inhibits rust and chemical degradation but also supports eventual ecological restoration—native plants can root between stones, fostering habitat corridors. In European studies, PVC coated gabion systems exhibit a cradle-to-grave emission rate 30-55% lower than poured concrete alternatives, primarily due to lower material processing energy and permeability benefits. When subject to cyclical wetting and freeze-thaw, properly installed gabion structures report service lives exceeding a century, necessitating only periodic visual checks (semi-annual recommended). Field surveys in Japan (2019) found that over 93% of gabion installations older than three decades required either no intervention or minor topping up of infill stones, a stark contrast to the frequent repairs associated with traditional embankment methods.

Why gabion pvc coated is the Right Choice for Your Project

Choosing gabion pvc coated solutions offers a blend of longevity, strength, and ecological value unmatched by alternative systems. Empirical data demonstrates these structures outperform non-coated or low-grade mesh baskets in harsh environments, while facilitating green building objectives and aesthetic flexibility. With benefits like customizable sizing, proven worldwide applications, and significant cost-saving over their operational lifetime, they align perfectly with the latest trends in sustainable civil engineering. For engineers, architects, and asset managers targeting robust, low-maintenance, and environmentally integrated design, gabion pvc coated products deliver both technical superiority and a reduction in total cost of ownership—underlining their continued adoption in award-winning infrastructure and landscaping projects globally.

(gabion pvc coated)

FAQS on gabion pvc coated

Q: What is a gabion PVC coated?

A: A gabion PVC coated is a wire mesh cage filled with rocks, covered in a protective PVC layer. This coating increases corrosion resistance and lifespan. It's ideal for use in harsh environments.

Q: What are the benefits of a PVC coated gabion box?

A: PVC coated gabion boxes offer enhanced durability and weather resistance compared to standard gabions. The PVC layer prevents rust and extends service life. They're commonly used in riverbanks and retaining walls.

Q: Where can PVC coated gabion baskets be used?

A: PVC coated gabion baskets are widely used in landscaping, erosion control, and civil engineering projects. They're suitable for river channel protection, slope reinforcement, and decorative walls. The PVC coating makes them suitable for wet or corrosive conditions.

Q: How does the PVC coating on gabion wires help?

A: The PVC coating provides an extra protective barrier against moisture and chemicals. This helps prevent rust and wire degradation. It ensures gabions remain strong in challenging environments.

Q: Are gabion PVC coated baskets customizable in size?

A: Yes, PVC coated gabion baskets can be made in various sizes to suit your project. Customization allows for flexibility in design and application. Always consult your supplier for available options.

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories