Sep . 19, 2025 19:10 Back to list

Durable Hexagonal Gabion Box for Erosion Control & Retaining Walls

Navigating the Landscape of Erosion Control with Hexagonal Gabion Boxes

In civil engineering and environmental protection, innovative solutions are crucial for managing soil erosion, stabilizing slopes, and constructing robust retaining structures. Among these, the hexagonal gabion box stands out as a versatile, cost-effective, and environmentally conscious choice. This comprehensive guide delves into the technical intricacies, application benefits, and market dynamics surrounding these essential structural components, providing B2B decision-makers and engineers with insights into their value proposition from leading hexagonal gabion box suppliers and manufacturers.

The demand for resilient and sustainable infrastructure continues to drive innovation in construction materials. Gabion boxes, particularly those crafted from hexagonal wire mesh, offer a unique combination of flexibility, permeability, and durability, making them indispensable in diverse applications ranging from hydraulic engineering to landscape architecture. Understanding their manufacturing, technical specifications, and strategic advantages is key to leveraging their full potential in modern projects.

Industry Trends and Market Dynamics

The global market for gabion structures is experiencing sustained growth, primarily driven by increased investment in infrastructure development, rising awareness of environmental protection, and the imperative for sustainable construction practices. Regulatory frameworks promoting eco-friendly erosion control and flood management solutions further accelerate the adoption of gabions. Key trends influencing the market for hexagonal gabion box solutions include:

- Sustainable Infrastructure: A growing emphasis on materials with low environmental impact and high resilience. Gabions, being filled with natural stone, align perfectly with this trend.

- Climate Change Adaptation: Increased frequency of extreme weather events (heavy rainfall, flooding) necessitates robust and adaptable erosion control and flood defense mechanisms.

- Urbanization and Land Reclamation: Expansion of urban areas often requires slope stabilization, retaining walls, and land reinforcement, driving demand for efficient construction systems.

- Technological Advancements: Improvements in wire coating technologies (e.g., Galfan, PVC) enhance the service life and performance of gabions, expanding their application range in aggressive environments.

- Cost-Effectiveness: As construction costs rise, the economic advantages of gabions—lower installation costs and reduced need for heavy machinery—make them an attractive option for projects seeking long-term value.

Leading hexagonal gabion box suppliers and hexagonal gabion box manufacturers are continually innovating to meet these evolving demands, focusing on enhanced durability, easier assembly, and compliance with stringent international standards.

Manufacturing Process of the Hexagonal Gabion Box

The production of a high-quality hexagonal gabion box involves a meticulous process designed to ensure durability, strength, and longevity. The core material is typically high-grade low-carbon steel wire, carefully selected for its tensile strength and ductility.

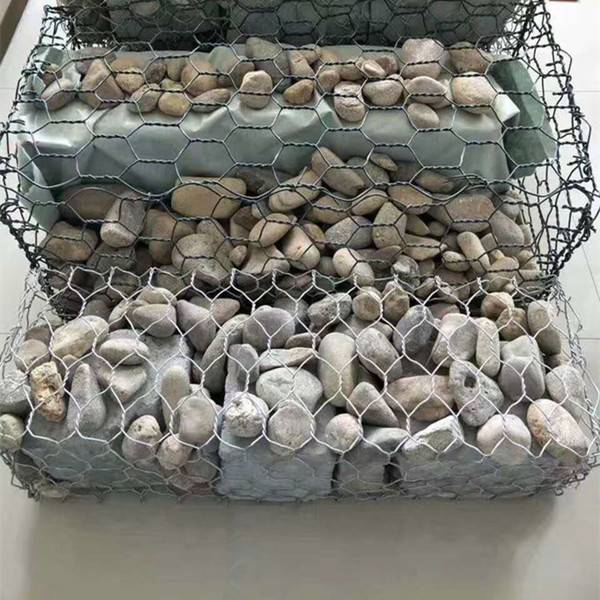

Figure 1: Illustration of a Hexagonal Gabion Box structure.

Process Flow:

- Wire Drawing: High-carbon steel rods are drawn through a series of dies to achieve the precise wire diameter required for the gabion mesh. This process enhances the wire's tensile strength.

- Corrosion Protection (Galvanization/Galfan Coating): The drawn wire undergoes hot-dip galvanization, where it's immersed in molten zinc to create a protective, sacrificial coating. For enhanced corrosion resistance, a Galfan (Zinc-5% Aluminum-Mischmetal) alloy coating may be applied, offering superior performance in aggressive environments.

- PVC Coating (Optional): For applications in highly corrosive conditions (e.g., saltwater, polluted water), a thick PVC coating is extruded onto the galvanized or Galfan-coated wire. This provides an additional layer of protection against chemical degradation and abrasion.

- Double-Twist Hexagonal Weaving: The coated wire is fed into specialized weaving machines that interlock adjacent wires in a double-twist pattern. This hexagonal mesh design provides exceptional structural integrity, preventing unraveling if a wire breaks.

- Cutting and Shaping: The continuous woven mesh is then cut into appropriate panel sizes according to standard or customized gabion dimensions. Diaphragms and end panels are also prepared.

- Edge Reinforcement: All edges of the gabion panels (main body, lids, diaphragms) are reinforced with heavier gauge wire (selvedge wire) to provide increased strength and maintain shape during assembly and filling.

- Quality Control and Testing: Throughout the process, strict quality control measures are implemented. This includes testing wire diameter, tensile strength, coating thickness, and mesh opening conformity against standards such as ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions) and EN 10223-3 (Steel wire and wire products for fencing and netting - Hexagonal steel wire mesh for civil engineering purposes).

- Folding and Packaging: The individual panels are then folded flat for efficient transportation and bundled, often secured with steel strapping or palletized.

The resulting hexagonal gabion box demonstrates superior service life, typically ranging from 25 to 75 years depending on the coating and environmental conditions. Target industries include civil engineering, hydraulic structures (e.g., river training, dam protection), mining (e.g., rockfall protection, erosion control), and landscaping (e.g., terracing, decorative walls). Advantages in typical scenarios include exceptional energy absorption from impacts, superior drainage capability reducing hydrostatic pressure, and outstanding corrosion resistance owing to multi-layered protective coatings.

Technical Specifications & Parameters

Understanding the precise technical specifications is paramount when specifying a hexagonal gabion box for critical engineering applications. These parameters dictate the structural integrity, durability, and suitability for various environmental conditions.

Standard Specifications for Hexagonal Gabion Box:

| Parameter | Typical Range / Specification | Notes / Standards |

|---|---|---|

| Mesh Wire Diameter | 2.0 mm to 4.0 mm | Influences overall strength; ASTM A975, EN 10223-3 |

| Selvedge Wire Diameter | 0.5 mm to 1.0 mm thicker than mesh wire | For edge reinforcement; enhances stability |

| Lacing Wire Diameter | 2.2 mm (common) | Used for assembly and internal bracing |

| Mesh Opening Size (HxW) | 60x80 mm, 80x100 mm, 100x120 mm | Common sizes; dictates stone fill size and permeability |

| Standard Box Dimensions (LxWxH) | 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m, 3x1x0.5m | Modular for various structural configurations |

| Coating Type | Hot-dip Galvanized, Galfan (Zn-5Al), PVC Coated | Determines corrosion resistance and lifespan |

| Minimum Zinc/Galfan Coating Mass | 240-290 g/m² (for 2.7mm wire) | Critical for corrosion protection; tested per ASTM A90 |

| PVC Coating Thickness | Minimum 0.5 mm | Provides additional chemical and abrasion resistance |

| Tensile Strength | 380-550 N/mm² | Ensures structural stability and resistance to deformation |

These specifications are carefully chosen to ensure that the gabion structures can withstand environmental stresses, absorb hydrostatic pressures, and maintain their form and function over their intended service life, which can exceed 75 years for PVC-coated systems in favorable conditions.

Technical Advantages and Performance

The inherent design and material properties of a hexagonal gabion box confer several significant technical advantages that make it a preferred solution in geotechnical and hydraulic engineering.

- Flexibility: Unlike rigid structures, gabions can tolerate differential settlement without loss of structural integrity. This adaptability makes them ideal for unstable ground conditions or areas prone to seismic activity. The double-twist mesh allows for minor deformation while maintaining continuity.

- Permeability: The open mesh structure, filled with stone, allows for efficient water drainage, preventing the buildup of hydrostatic pressure behind retaining structures. This eliminates the need for complex and costly drainage systems, thereby enhancing stability and reducing the risk of structural failure due to uplift forces.

- Durability and Longevity: High-quality galvanized, Galfan-coated, or PVC-coated wire ensures exceptional resistance to corrosion, abrasion, and weathering. When correctly specified and installed, gabion structures can last for decades, even in harsh environmental conditions.

- Environmental Compatibility: Gabions are eco-friendly. They utilize readily available local stone fill, reducing transportation costs and carbon footprint. The porous nature encourages vegetation growth, promoting natural habitat restoration and integrating seamlessly into landscapes over time.

- Cost-Effectiveness: The simplicity of gabion construction reduces labor costs and the need for specialized equipment. Sourcing local fill material further contributes to overall project savings, offering significant long-term economic benefits compared to conventional concrete or masonry structures.

- Ease of Installation: Gabion boxes are supplied in flat-pack form, making transportation efficient. Assembly is straightforward, requiring minimal training and often no heavy machinery, allowing for rapid deployment in remote or challenging terrains.

Figure 2: Permeability of gabion structures allows for efficient drainage.

These advantages collectively position gabions as a superior choice for various engineering challenges, providing robust, sustainable, and economically viable solutions.

Application Scenarios & Case Studies

The versatility of the hexagonal gabion box allows for its deployment across a broad spectrum of civil engineering and environmental applications. Its adaptability to various site conditions and aesthetic integration make it a preferred material for both functional and decorative purposes.

Typical Application Areas:

- Erosion Control: Critical for stabilizing riverbanks, coastal defenses, and steep slopes, preventing soil loss and maintaining landscape integrity. Their permeability dissipates wave energy and allows natural revegetation.

- Retaining Walls: Used in gravity retaining walls for road embankments, bridge abutments, and terraced landscapes. Their mass and flexibility provide stable support, especially on compressible foundations.

- Channel Linings and Weirs: Protect water channels from scour and erosion, maintaining hydraulic efficiency and controlling water flow.

- Rockfall Protection: Gabion fences and drapery systems are highly effective in containing and preventing rockfalls in mountainous regions, quarry sites, and along transportation corridors.

- Architectural and Landscaping Features: Increasingly employed for aesthetically pleasing façades, decorative walls, garden features, and sound barriers, blending functionality with modern design.

- Mine Site Rehabilitation: Used for stabilizing tailings dams, constructing erosion barriers, and restoring disturbed landscapes in mining areas.

Figure 3: Gabion baskets forming a robust retaining wall structure.

Case Study Snippet: Riverbank Stabilization Project

A major river in Southeast Asia, known for its seasonal flooding and severe bank erosion, required a sustainable solution to protect nearby agricultural land and infrastructure. Engineers opted for a gabion mattress and hexagonal gabion box retaining wall system. Over 10,000 cubic meters of gabion structures were deployed along a 2-kilometer stretch. The permeable nature of the gabions allowed the river to interact naturally with the banks during fluctuating water levels, reducing hydrostatic pressure and allowing vegetation to establish within the voids over time. Post-installation, the riverbanks demonstrated significant stability, successfully withstanding multiple flood events, and showing strong ecological integration with local flora. This project highlighted the gabions' resilience, environmental benefits, and cost-effectiveness compared to traditional concrete structures.

Vendor Comparison: Choosing the Right Manufacturer

Selecting the right hexagonal gabion box manufacturers is a critical decision that impacts project success, longevity, and budget. While many hexagonal gabion box suppliers exist, distinguishing between them requires a careful evaluation of several factors beyond just price.

Key Comparison Factors:

- Quality Certifications: Look for manufacturers adhering to international standards such as ISO 9001, ASTM A975, and EN 10223-3. Certifications validate their commitment to quality control and product consistency.

- Material Sourcing and Coating Expertise: Inquire about the origin and quality of raw steel wire and the types of corrosion protection offered (e.g., hot-dip galvanization, Galfan, PVC coating). Superior coatings significantly extend product lifespan.

- Manufacturing Capacity and Lead Times: Ensure the manufacturer has the capacity to meet project deadlines, especially for large-scale orders. Reliable lead times are crucial for project scheduling.

- Technical Support and Engineering Services: A reputable manufacturer offers design assistance, technical specifications, installation guides, and post-sales support, crucial for complex projects.

- Customization Capabilities: The ability to provide bespoke dimensions, wire gauges, or specialized coatings for unique project requirements.

- Reputation and Project Portfolio: Review case studies, client testimonials, and the company's experience in similar applications. A strong track record signifies reliability and expertise.

Figure 4: Close-up of hexagonal wire mesh, highlighting double-twist weaving.

Comparison of Gabion Wire Coatings:

| Coating Type | Composition | Corrosion Resistance | Expected Lifespan (Typical) | Primary Applications |

|---|---|---|---|---|

| Hot-dip Galvanized | 100% Zinc | Good, sacrificial protection | 25-30 years | General civil engineering, non-aggressive environments |

| Galfan (Zn-5Al) | Zinc-5% Aluminum-Mischmetal alloy | Superior, 2-3 times better than galvanized | 40-60 years | Moderately aggressive environments, enhanced durability |

| PVC Coated (over Galfan/Galvanized) | Polyvinyl Chloride layer over metallic coating | Excellent, abrasion and chemical resistance | 50-75+ years | Highly aggressive environments (saltwater, acidic soils), aesthetics |

A careful evaluation of these factors ensures that the selected gabion product aligns with project requirements and offers optimal long-term performance.

Customized Solutions & Design Considerations

While standard hexagonal gabion box dimensions and specifications meet most project needs, complex or unique applications often benefit from customized solutions. Leading manufacturers offer flexible production capabilities to tailor gabions to specific design requirements.

- Bespoke Dimensions: Gabions can be manufactured in non-standard lengths, widths, or heights to fit intricate site geometries, optimize material usage, or achieve specific aesthetic outcomes.

- Varying Wire Gauges: Depending on the anticipated loads, environmental exposure, and design life, the mesh wire and selvedge wire diameters can be adjusted to provide increased strength or cost efficiency.

- Specialized Coatings: For environments with extreme corrosive agents (e.g., highly acidic or alkaline soils, industrial effluents), specialized PVC compounds or alternative protective coatings can be applied.

- Geotextile Integration: Custom designs can incorporate geotextile filters or separators within or behind gabion structures to enhance filtration, prevent fine soil migration, or improve drainage.

- Integrated Design Support: Reputable manufacturers often provide engineering support, helping clients design optimal gabion solutions, including calculating stability, determining appropriate configurations, and suggesting filling methods.

This level of customization ensures that the gabion solution is perfectly aligned with project objectives, maximizing performance and efficiency while adhering to budgetary constraints.

Quality Assurance, Certifications, and Partnerships

Commitment to quality is the cornerstone of reliable B2B supply. Our manufacturing processes for the hexagonal gabion box adhere strictly to international quality management standards, ensuring consistent product performance and customer satisfaction.

- ISO 9001 Certification: Our facilities operate under ISO 9001 certified quality management systems, guaranteeing rigorous checks at every stage, from raw material inspection to final product packaging.

- Compliance with Industry Standards: All gabion products meet or exceed established standards such as ASTM A975-97 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses) and EN 10223-3 (Steel wire and wire products for fencing and netting – Hexagonal steel wire mesh for civil engineering purposes).

- Extensive Testing Regimens: Our products undergo comprehensive testing for wire tensile strength, coating adhesion and thickness, and mesh integrity to ensure optimal performance in real-world conditions.

- Trusted Partnerships: Over many years, we have cultivated strong relationships with a diverse range of clients across civil engineering, hydraulic works, and environmental protection sectors, earning a reputation for reliability and excellence.

These commitments underscore our dedication to delivering only the highest quality hexagonal gabion box solutions, backed by verifiable credentials and a proven track record.

Trustworthiness Module: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

-

Q: What is the ideal stone fill size for a hexagonal gabion box?

A: The stone fill size should generally be 1.5 to 2 times larger than the mesh opening to prevent stones from falling out. For an 80x100mm mesh, a stone size between 100mm and 200mm is typically recommended. -

Q: How do gabions handle differential settlement?

A: The double-twist hexagonal mesh provides inherent flexibility, allowing the gabion structure to deform and adjust to minor ground movements without cracking or losing structural integrity, unlike rigid concrete structures. -

Q: Can gabions be used in saltwater environments?

A: Yes, for marine or highly corrosive environments, PVC-coated gabions are strongly recommended. The PVC layer offers superior chemical and abrasion resistance, significantly extending the service life of the structure. -

Q: Is specialized labor required for gabion installation?

A: While basic construction skills are beneficial, gabion installation is relatively straightforward. We provide detailed instruction manuals and can offer technical guidance to ensure proper assembly and filling techniques.

Lead Time & Fulfillment

Our standard lead time for typical orders of hexagonal gabion box units ranges from 2 to 4 weeks, depending on order volume and specific customization requirements. For urgent or large-scale projects, we encourage direct consultation to establish an optimized production and delivery schedule. We maintain efficient logistics partnerships to ensure timely and secure global delivery.

Warranty Commitments

We stand behind the quality of our products. All gabion box hexagonal wire mesh products come with a comprehensive material and workmanship warranty against manufacturing defects. The specific warranty duration varies based on the coating type:

- Hot-dip Galvanized Gabions: 5-year warranty.

- Galfan (Zinc-5% Aluminum) Gabions: 10-year warranty.

- PVC Coated Gabions: 15-year warranty.

These warranties cover defects arising from the manufacturing process under normal usage conditions. Detailed terms and conditions are available upon request.

Customer Support

Our dedicated customer support team is available to assist with inquiries, technical specifications, order status, and after-sales support. You can reach us via phone at [Insert Phone Number] or email at [Insert Email Address]. Our technical experts are ready to provide guidance, ensuring your project proceeds smoothly from concept to completion.

Figure 5: Hexagonal gabion box ready for deployment in an engineering project.

Conclusion

The hexagonal gabion box remains a cornerstone in modern civil engineering and environmental protection, offering a dynamic blend of strength, flexibility, permeability, and sustainability. From robust retaining walls to critical erosion control systems, its applications are as diverse as the engineering challenges it addresses. By prioritizing high-quality materials, advanced manufacturing processes, and adherence to international standards, leading hexagonal gabion box manufacturers provide solutions that are not only technically superior but also economically viable and environmentally responsible. As infrastructure demands continue to grow, the strategic adoption of gabion technology will be pivotal in building resilient and sustainable environments for the future.

References

- ASTM A975/A975M-11(2017), Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses (Metallic-Coated Steel Wire or Metallic-Coated Steel Wire With Poly(Vinyl Chloride) (PVC) Coating), ASTM International, West Conshohocken, PA, 2017, www.astm.org

- EN 10223-3:2013, Steel wire and wire products for fencing and netting - Part 3: Hexagonal steel wire mesh for civil engineering purposes, European Committee for Standardization, 2013.

- International Gabion Organization (IGO). (n.d.). Gabion design and application guidelines. Retrieved from reputable civil engineering resources on gabions.

- Maccaferri, G. (2018). Gabions and related structures: a review of current design practices. Geotechnical Engineering Journal, 48(2), 123-135.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories