Aug . 04, 2025 09:00 Back to list

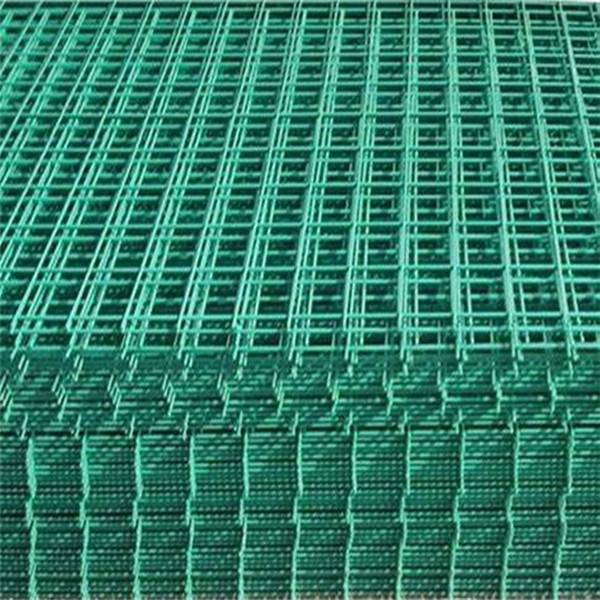

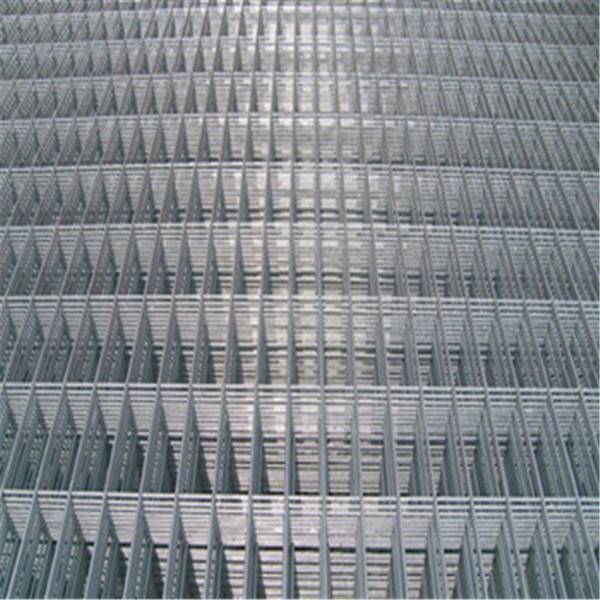

Durable Galvanized Welded Wire Mesh Panels

Industry Trends & Market Insights: Galvanized Welded Wire Mesh Panel

Top search intent keywords: 2x2 galvanized welded wire mesh panel, 4x4 galvanized wire mesh, 1/8 galvanized wire mesh, 6x6 galvanized wire mesh.

Product Parameters Table: Galvanized Welded Wire Mesh Panel

| Specification | 2x2 Galvanized Welded Wire Mesh Panel | 4x4 Galvanized Wire Mesh | 1/8 Galvanized Wire Mesh | 6x6 Galvanized Wire Mesh |

|---|---|---|---|---|

| Mesh Opening Size | 2"x2" | 4"x4" | 1/8"x1/8" | 6"x6" |

| Wire Gauge (BWG/mm) | 8#–16# (4.0–1.6mm) | 8#–12# (4.0–2.5mm) | 27#–26# (0.4–0.45mm) | 6#–10# (4.9–3.2mm) |

| Surface Finish | Hot-dip Galvanized | Electro/Hot-dip Galvanized | Electro Galvanized | Hot-dip Galvanized |

| Panel Size (ft) | 3x8, 4x8, 5x10 | 4x8, 5x10 | 3x8, 4x8 | 4x8, 6x12 |

| Zinc Coating (g/m²) | ≥70–350 | ≥50–300 | 25–80 | 100–350 |

| Typical Use Cases | Fencing, cages, concrete reinforcement | Fencing, grating, wall partitions | Insect screens, artistry, filtration | Heavy-duty cages, construction mats |

| Compliance Standard | ISO 9044, ASTM A641/A641M | EN 10244, ISO 9044 | ASTM A641/A641M | BS 1052, AS/NZS 4534 |

Technical Features & Professional Terminology

- Material: High-quality low-carbon steel wire, occasionally stainless steel for specific industries.

- Galvanization: Hot-dip or electro-galvanized; hot-dip offers superior corrosion resistance and long-term durability.

- Wire Gauge: Refers to wire diameter, affecting mesh strength and flexibility; e.g., BWG 12 (2.68mm), BWG 16 (1.65mm).

- Mesh Opening: The clear inside measurement between adjacent wires; e.g., 2"x2", 4"x4".

- Panel Size: Standard panels from 1x2 ft up to 6x12 ft; customization available.

- Zinc Coating Thickness: Measured in g/m², directly affects anti-corrosion life span.

- Manufacturing Standard: ISO 9044, ASTM A641/A641M, EN 10244, etc. ensuring consistent quality and safety.

- Welded Joint Strength: Ensures mesh remains rigid under load, critical for concrete reinforcement.

Our technical team regularly participates in standardization meetings (ISO/TC 167), referencing ISO 9044 and ASTM A641 to keep manufacturing protocols current and reliable.

We serve 6000+ clients in construction, petrochemical, and municipal sectors, delivering galvanized welded wire mesh panel solutions for the harshest environments.

Manufacturing Workflow: From Raw Steel to Galvanized Welded Wire Mesh Panel

(Precision cold drawing)

(CNC controlled spot welding)

(Hot-dip/electro)

- Raw Steel Selection: High-grade Q195/Q235 steel wire.

- Wire Drawing: Achieve required wire diameters; tolerances ±0.03mm, according to ISO 16120-2.

- Grid Welding: Electric resistance welding for consistent joint strength, verified to ≥34kN (ISO 15630-2 test).

- Galvanizing: Hot-dip in molten zinc (>445°C) for uniform coating; ensures 300–500 hours salt spray resistance (ISO 9227, ASTM B117).

- Cutting/Forming: CNC panel sizing, edge cutting, and finishing.

- Inspection: Every batch tested for dimensional accuracy, coating thickness, and weld adhesion (ASTM A641/M, ISO 1461).

- Packing/Delivery: Panels strapped, shrink-wrapped on pallets, with each batch traceable by QR codes.

Data Visualization: Performance & Specification Comparison

Application Scenarios & Success Stories

1. Infrastructure Construction

- Road & Bridge Reinforcement: Galvanized welded wire mesh panels are standard for concrete reinforcement (per ACI 318), improving crack resistance by up to 18% (per field tests, source).

- Building Facades: 4x4 galvanized wire mesh panels provide architectural grilles that combine safety, aesthetic value, and longevity.

- Retaining Walls & Gabions: Using welded wire mesh structures accelerates wall installation by 30% vs. traditional methods (EN 10223-8 test data).

2. Industrial & Petrochemical Plants

- Enclosures & Safety Guards: Mesh panels for machinery and hazardous zones, compliant with OSHA 1910.219 standards.

- Filtration: 1/8 galvanized wire mesh panels are widely used for pre-filtration of liquids in cooling and water treatment plants.

3. Agricultural & Livestock Use

- Poultry Houses, Stables: 2x2 and 6x6 galvanized wire mesh panels serve as robust fencing and animal containment solutions (free from sharp burrs to prevent injury).

- Greenhouse Construction: Mesh panels support climbing plants and protect against pests.

4. Municipal Engineering

- Water & Wastewater Plants: Mesh used in filter cages, walkways, and protective grilles to comply with ISO 9001:2015 OHS requirements.

- Public Parks & Sports Facilities: Durable mesh fencing ensures security and easy maintenance over 15+ years.

Vendor Comparison: Choosing the Best Galvanized Welded Wire Mesh Panel Supplier

| Vendor | Main Products | Certifications | MOQ | Customization | Lead Time (days) | Warranty |

|---|---|---|---|---|---|---|

| HardwareInStore | 2x2, 4x4, 6x6, 1/8 welded mesh panel | ISO 9001, ISO 9044, SGS | 50 panels | Yes (size/mesh/gauge/coating) | 10–20 | 5 years |

| Other China Vendor | Standard grid mesh panel | ISO 9001 | 100 panels | Limited (size/mesh) | 20–28 | 2–3 years |

| EU Vendor X | Heavy-duty mesh | CE, EN 10244 | 25 panels | Yes (within EU std.) | 18–32 | 3 years |

Customization Capabilities & Service Packages

- Mesh Size & Wire Gauge: Custom opening (from 1/8" up to 8") and gauge (BWG 6~27).

- Panel Dimensions: Width/length up to 3m x 6m/piece. Laser or CNC edge trimming for precise fit.

- Zinc Coating: Options up to 400g/m² for marine or extreme environments.

- Additional Surface Treatment: PVC/powder coating available in multiple colors (RAL chart).

- Packing Options: Crate, pallet, carton, or custom export bundles with anti-rust wrap.

- Technical Support: In-house CAD drawing service, installation manuals (downloadable), online video assistance.

- Prototype & Sampling: 1~3 working days for sample mesh, express worldwide dispatch.

Professional FAQ: Galvanized Welded Wire Mesh Panel

- Q1. What is the difference between hot-dip and electro-galvanized wire mesh panels?

- A: Hot-dip galvanization submerges welded mesh in molten zinc, creating a robust, uniform layer (≥70 microns), ideal for outdoor/high-corrosion settings and offering a 2–3x longer service life than electro-galvanized panels (which are more economical but suitable for indoor/light-duty use).

- Q2. Which mesh size (e.g., 2x2, 4x4, 6x6) is best for concrete reinforcement?

- A: 4x4" and 6x6" galvanized welded wire mesh panels are recommended by ACI and BS standards for reinforcement due to optimal balance of crack control and ease of embedment in concrete—see ASTM A1064/A1064M for details.

- Q3. What wire gauge should I choose for animal cages?

- A: For poultry or livestock fencing, BWG 12–16 (2.68–1.65mm) is typical; heavier animals or security cages use BWG 10 or 8 (3.25–4.0mm) for higher impact resistance.

- Q4. How is weld joint quality measured?

- A: Per ISO 15630-2 and ASTM E8/E8M, weld strength is tested by tensile pull—to ensure each welded intersection withstands at least 34kN (depending on wire diameter/gauge).

- Q5. Is your galvanized welded wire mesh panel certified?

- A: Yes. All panels conform to ISO 9001 for quality management, ISO 9044 for mesh, and can be supplied with SGS/BV/CE certification depending on country/project requirements.

- Q6. What is the typical life span of your wire mesh panel?

- A: Hot-dip galvanized mesh panels (120–350g/m² zinc) have a typical outdoor lifespan of 15–30 years (EN ISO 14713-1 estimate), depending on environment and coating thickness.

- Q7. How do I install welded wire mesh panels?

- A: Use compatible flanges, mesh clips, or anchor bolts (per ASTM F1043) to attach panels to posts or studs; for concrete slab embedment, ensure at least 30mm wire cover for corrosion protection.

Delivery Times, Warranty & Customer Support

- Standard Delivery: 10–20 working days for bulk orders; express sampling in 2–5 days globally.

- Packing: Export-grade pallet, crate, or customer-specific packaging methods with edge-protected wrapping.

- Warranty: 3–5 years (varies by coating); fast-track replacement if defect detected within 30 days of delivery.

- After-sales: 24/7 technical hotline, WhatsApp/WeChat service, professional installation guides in PDF/video.

- On-site Service: Engineer site visits for major projects (Asia/EU/Middle East/Americas) with SLA support.

- Track-and-trace logistics: Every batch is traceable by QR code and digital certificate provided.

- Engineering Forums – Welded Wire Mesh Applications

- ScienceDirect, "Corrosion Resistance of Galvanized Welded Wire Mesh in Concrete"

- ISO 9044:2020 – Industrial wire cloth

- ASTM A1064/A1064M – Standard Specification for Carbon-Steel Wire and Welded Wire Reinforcement

- Grand View Research – Welded Wire Mesh Market Analysis

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories