Sep . 10, 2025 11:00 Back to list

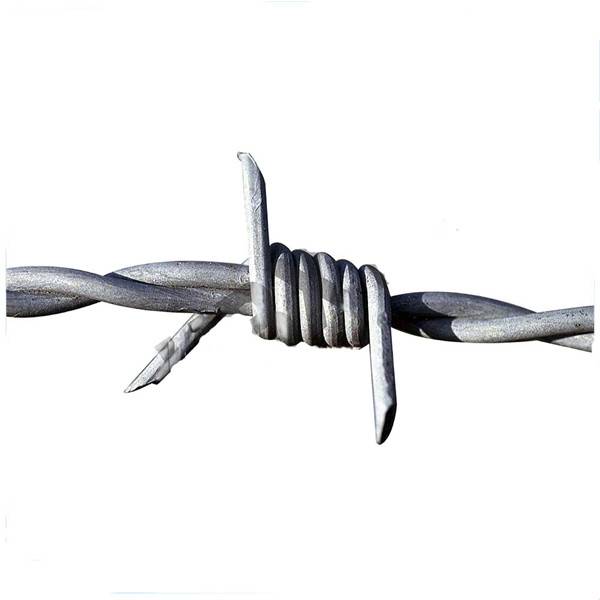

Durable Barbed Wire: Secure Fencing, Mesh & Flat Options

The Strategic Role of Galvanized Barbed Wire in Modern Security Infrastructures

In an era where robust perimeter security is paramount for industrial, commercial, and agricultural sectors, the demand for reliable and cost-effective deterrents is steadily increasing. Among the most enduring and effective solutions is barbed wire, a fundamental component in fencing systems designed to prevent unauthorized access. This article delves into the technical aspects, applications, and strategic advantages of modern galvanized barbed wire, underscoring its relevance in today's security landscape.

Industry Trends and Market Dynamics

The global security fencing market continues to expand, driven by heightened concerns over property protection, critical infrastructure safeguarding, and agricultural security. Innovation in materials and coating technologies has significantly enhanced the performance and longevity of fencing products. Key trends include the integration of advanced anti-corrosion treatments, such as heavy-duty galvanization, and the development of specialized designs like flat barbed wire and Razor Barbed Tape (RBT) for enhanced deterrence. The market sees a consistent demand for versatile solutions, from standard perimeter security to high-security installations requiring superior resistance to cutting and climbing. The adaptability of the barbed wire system, combined with its relatively low barbed wire cost, ensures its continued prominence.

The focus for B2B procurement remains on durability, ease of installation, and compliance with international standards. Manufacturers are continually refining production processes to meet these stringent requirements, ensuring that products like galvanized barbed wire deliver maximum value and operational reliability over extended service lives.

Manufacturing Process: Crafting Durable Galvanized Barbed Wire

The production of high-quality galvanized barbed wire is a precise multi-stage process, meticulously controlled to ensure superior strength and corrosion resistance. Understanding this process is crucial for B2B clients evaluating product quality and long-term performance.

Detailed Process Flow:

- Wire Rod Selection: The foundation is high-carbon steel wire rod, selected for its inherent tensile strength. Raw materials conform to ASTM A853 standards for steel wire.

- Wire Drawing: The steel rod undergoes a cold-drawing process, reducing its diameter to the desired gauge while increasing its tensile strength and ductility. This precise operation prepares the wire for subsequent steps.

- Cleaning and Pickling: Before galvanization, the wire is thoroughly cleaned to remove scale, rust, and impurities. This typically involves acid pickling followed by rinsing, ensuring optimal adhesion of the zinc coating.

- Hot-Dip Galvanization: The clean wire is passed through a molten zinc bath at temperatures around 450°C (840°F). This process creates a metallurgically bonded zinc layer on the steel surface, providing exceptional corrosion resistance. The thickness of the zinc coating is a critical parameter, often meeting or exceeding ASTM A121 standards.

- Barb Formation and Twisting: Two strands of galvanized line wire are twisted together to form the main wire. Simultaneously, shorter pieces of galvanized barb wire are cut and twisted around one or both line wires at specified intervals, creating the characteristic sharp barbs. This ensures consistent barb spacing and robust attachment.

- Coiling and Packaging: The finished barbed wire is then coiled into precise lengths, such as 100m barbed wire rolls, and securely packaged for shipping and handling.

Throughout this process, stringent quality control measures are in place, aligning with ISO 9001:2015 quality management system standards. Testing includes tensile strength, zinc coating adherence, and uniformity checks. The resulting product exhibits superior corrosion resistance, ensuring a service life of 15-20 years or more, depending on environmental conditions. Target industries benefiting from this robust product include agriculture, industrial facilities, border security, and general infrastructure projects, where its durable construction makes it ideal for long-term security applications.

Technical Specifications and Performance Parameters

For B2B clients, precise technical specifications are crucial for ensuring compatibility, performance, and compliance with project requirements. Our galvanized barbed wire is engineered to meet exacting standards, offering reliable security solutions.

Standard Product Specifications:

| Parameter | Description | Standard Value / Range |

|---|---|---|

| Material | High-carbon steel (Q195/Q235 equivalent) | Galvanized iron barbed wire |

| Surface Treatment | Hot-dip galvanized | ASTM A121 Class 1 or 2 |

| Line Wire Gauge | Diameter of main wires | 12.5 gauge (2.5mm) to 15.5 gauge (1.8mm) |

| Barb Wire Gauge | Diameter of barb wires | 14 gauge (2.0mm) to 16 gauge (1.6mm) |

| Barb Spacing | Distance between barbs | 3 inches (7.6 cm) to 6 inches (15.2 cm) |

| Strand Configuration | Number of line wires and points per barb | 2-strand, 4-point; 2-strand, 2-point |

| Tensile Strength | Resistance to breaking under tension | High Tensile: 80,000 psi min; Mild Steel: 45,000 psi min |

| Roll Lengths | Standard package lengths | 50m, 100m barbed wire, 200m, 500m |

| Zinc Coating Weight | Amount of zinc per unit area | Min. 240 g/m² for heavy galvanized |

These specifications highlight the robustness and compliance of our galvanized barbed wire rope, ensuring it meets diverse industry demands. The heavy galvanization process significantly extends the material's lifespan, offering an excellent return on investment by minimizing maintenance and replacement cycles.

Application Scenarios and Technical Advantages

The versatility and inherent deterrent qualities of galvanized barbed wire make it indispensable across a wide spectrum of applications where perimeter security is critical. Its technical advantages offer significant benefits over alternative solutions.

Typical Application Scenarios:

- Agricultural Fencing: Widely used for livestock containment and protecting crops from wildlife. Its robust construction ensures long-term viability in demanding outdoor environments.

- Industrial and Commercial Perimeter Security: Essential for securing construction sites, factories, warehouses, and storage facilities, often integrated with chain-link or rigid panel fencing.

- High-Security Installations: Augmenting existing security measures around sensitive areas such as power plants, military bases, and correctional facilities, particularly with concertina wire (RBT barbed wire) installations.

- Border Control and Property Lines: Providing clear demarcation and a significant physical deterrent along property boundaries and national borders.

Technical Advantages:

- Superior Corrosion Resistance: The hot-dip galvanized coating provides an exceptionally durable barrier against rust and environmental degradation, significantly extending the product's service life compared to untreated or lightly galvanized wire. This reduces long-term maintenance costs.

- High Deterrent Capability: The sharp barbs and inherent rigidity of the wire present a formidable physical and psychological barrier, effectively deterring intruders and unauthorized access.

- Cost-Effectiveness: Compared to other high-security fencing options, barbed wire offers a highly economical solution both in terms of initial purchase and installation, representing excellent value for securing large perimeters. This makes the overall barbed wire cost attractive for extensive projects.

- Ease of Installation and Adaptability: Lightweight yet strong, it can be easily installed on various fence types (e.g., wooden posts, metal poles, concrete walls) and readily adapted to different terrain, reducing labor and equipment requirements.

- Durability and Minimal Maintenance: Its robust construction and protective coating ensure resilience against physical impact and harsh weather conditions, requiring minimal upkeep once installed.

While barbed wire mesh provides a more solid barrier, standard barbed wire excels in creating an effective deterrent top line for fences, or as a standalone agricultural barrier, offering optimal balance between security and expenditure.

Vendor Comparison and Customized Solutions

Selecting the right supplier for barbed wire is critical for ensuring product quality, timely delivery, and long-term support. B2B decision-makers must consider not only technical specifications but also a vendor's ability to offer tailored solutions and reliable service.

Key Factors for Vendor Comparison:

| Factor | Leading Vendor (Our Offering) | Generic Vendor A | Generic Vendor B |

|---|---|---|---|

| Material Quality | High-carbon steel (Q195/Q235), ASTM compliant | Standard steel, varied quality | Recycled or low-grade steel |

| Galvanization Standard | Heavy Hot-Dip (Min. 240 g/m²), ASTM A121 Class 2 | Electro-galvanized or Light Hot-Dip ( | Minimal coating, poor adhesion |

| Product Certifications | ISO 9001, ASTM, SGS inspected | Basic internal quality control | None specified |

| Customization Options | Wire gauge, barb spacing, roll length, coating type | Limited standard sizes only | No customization |

| Lead Time & Logistics | Efficient production, global shipping network | Standard, potentially longer for bulk orders | Unpredictable, limited shipping options |

| After-Sales Support | Comprehensive, technical consultation, warranty | Basic support, limited warranty | Minimal to no support |

Customized Solutions:

Recognizing that every B2B project has unique security requirements, we offer extensive customization options for our galvanized barbed wire. This includes:

- Specific Wire Gauges: From lighter gauges for temporary fencing to heavier gauges for high-security perimeters.

- Barb Configurations: Custom barb spacing (e.g., closer for enhanced deterrence) and 2-point or 4-point barb designs.

- Roll Lengths and Packaging: Tailored roll lengths beyond the standard 100m barbed wire to minimize waste and optimize installation efficiency for large-scale projects.

- Specialty Coatings: Beyond standard galvanization, options for PVC coating or additional protective layers for extreme environmental conditions.

Our engineering team collaborates closely with clients to develop solutions that perfectly match technical specifications and budget constraints, ensuring optimal performance and project success.

Application Case Studies: Galvanized Barbed Wire in Action

Real-world applications demonstrate the effectiveness and reliability of galvanized barbed wire. These case studies highlight its strategic deployment in diverse B2B contexts.

Case Study 1: Agricultural Estate Perimeter Enhancement

Client: Large-scale commercial farm in a rural area.

Challenge: Frequent incursions by local wildlife and opportunistic trespassers leading to crop damage and equipment theft. Existing basic wire fencing was insufficient.

Solution: Installation of a multi-strand galvanized barbed wire system atop an existing chain-link fence, coupled with standalone barbed wire rope fencing along less trafficked perimeter sections. We supplied over 10,000 meters of 12.5 gauge, 4-point barbed wire.

Outcome: Within three months, reported incidents of trespassing and animal-related damage decreased by over 80%. The long-lasting galvanized coating ensured minimal maintenance despite harsh weather, providing a cost-effective and highly effective security upgrade.

Case Study 2: Industrial Complex Security Upgrade

Client: Mid-sized manufacturing plant with valuable inventory and sensitive equipment.

Challenge: The existing perimeter fence was aging and lacked sufficient deterrent features, making it vulnerable to unauthorized entry attempts. High security areas required immediate reinforcement.

Solution: We provided heavy-duty galvanized barbed wire in a concertina (RBT barbed wire) configuration for the most critical sections, and a traditional 3-strand barbed wire extension on top of the entire existing fence line. All materials met ISO 9001 and ASTM standards.

Outcome: The enhanced physical barrier immediately deterred potential intruders. Over the subsequent year, security breach attempts dropped to zero. The investment in robust, galvanized material promised decades of service life, outperforming the previous setup in terms of both security and longevity, thereby reducing the overall barbed wire cost over its lifecycle.

Trustworthiness and Customer Support

Our commitment to B2B clients extends beyond providing high-quality barbed wire products. We prioritize transparency, reliability, and comprehensive support to foster long-term partnerships.

Frequently Asked Questions (FAQ):

- Q: What is the typical lead time for a bulk order of galvanized barbed wire?

- A: Standard lead times range from 7-14 business days, depending on order volume and specific customization requirements. Expedited options are available upon request.

- Q: What certifications does your barbed wire adhere to?

- A: Our products are manufactured under ISO 9001:2015 certified quality management systems and meet relevant ASTM standards, specifically ASTM A121 for barbed wire and ASTM A90 for zinc coating.

- Q: Can you provide installation guidance or recommend installers?

- A: While we primarily supply materials, our technical support team can offer best practice guidance for installation and, for larger projects, connect you with trusted installation partners.

- Q: How does your galvanized barbed wire compare to PVC coated options?

- A: Galvanized barbed wire offers superior impact resistance and is generally more cost-effective. PVC coated options provide an additional layer of aesthetic appeal and can offer enhanced corrosion resistance in highly corrosive environments, albeit at a higher initial cost. Both are excellent choices depending on specific project needs.

Lead Time & Fulfillment:

We operate a streamlined supply chain to ensure efficient order processing and timely delivery. Standard orders are typically fulfilled within 7-14 business days. For large-scale projects or custom specifications, our team provides detailed production schedules and logistics plans. We leverage a robust global shipping network to ensure reliable delivery to your project site.

Warranty Commitments:

Our galvanized barbed wire products come with a comprehensive warranty against manufacturing defects and premature corrosion under normal operating conditions. The duration of the warranty is determined by the specific product grade and galvanization standard, typically ranging from 5 to 20 years for our heavy hot-dip galvanized products. Full warranty details are available upon request.

Customer Support:

Our dedicated B2B customer support team is available to assist with product selection, technical inquiries, order tracking, and after-sales service. We offer personalized consultation to ensure you procure the optimal barbed wire solution for your specific application. Contact us via phone, email, or our online portal for prompt and expert assistance.

Conclusion

Galvanized barbed wire remains a cornerstone of effective perimeter security, offering an unparalleled combination of deterrence, durability, and cost-effectiveness. Through meticulous manufacturing processes, adherence to international standards, and continuous innovation in anti-corrosion technology, modern barbed wire provides a reliable solution for safeguarding assets across a multitude of industries. Our commitment to quality, customized solutions, and robust client support ensures that B2B clients receive products that not only meet but exceed their operational demands and security expectations.

Authoritative References:

- ASTM International. "ASTM A121 - 13(2018) Standard Specification for Metallic-Coated Carbon Steel Barbed Wire." ASTM International, West Conshohocken, PA, 2018.

- ISO. "ISO 9001:2015 Quality management systems — Requirements." International Organization for Standardization, 2015.

- The World Steel Association. "Life Cycle Assessment (LCA) Methodology for Steel Products." worldsteel.org.

- Galvanizers Association. "Hot Dip Galvanizing: A Guide to the Process and Its Applications." galvanizers.org.uk.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories