Sep . 11, 2025 10:20 Back to list

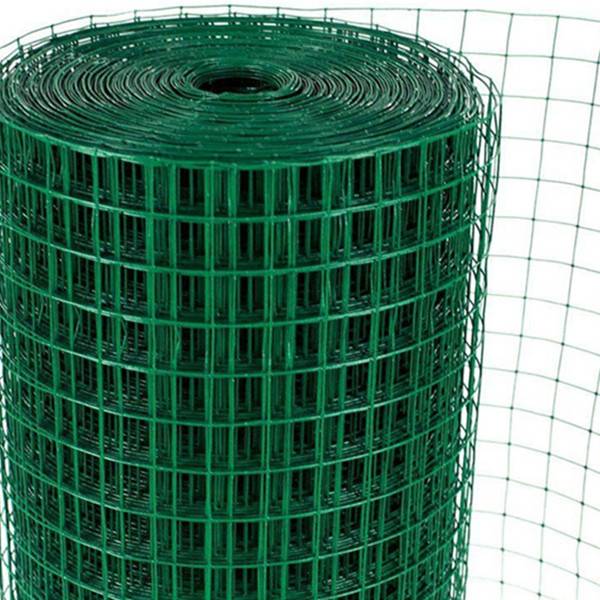

Buy PVC Coated Wire Mesh for Sale | Durable, Rust-Proof Fencing

Industry Trends and Market Dynamics for PVC Coated Wire Mesh

The global demand for high-performance protective barriers and enclosures continues to drive innovation in the wire mesh sector. Among the most sought-after solutions, pvc coated wire mesh for sale stands out due to its superior durability, aesthetic appeal, and cost-effectiveness. This material's market growth is primarily fueled by expanding infrastructure projects, heightened security concerns, and the increasing adoption of sustainable, long-lifecycle products across various industries.

Current industry trends indicate a strong preference for materials that offer extended service life and minimal maintenance requirements. PVC coating provides an additional layer of protection against environmental aggressors, making it ideal for both harsh outdoor conditions and demanding industrial applications. The market is also experiencing a shift towards customized solutions, with clients seeking specific mesh sizes, wire gauges, and color options to match diverse project specifications. This customization trend is particularly prevalent in sectors such as agriculture, construction, and public utilities, where specialized fencing and protective screens are critical.

Furthermore, the integration of advanced manufacturing technologies, such as automated welding and precision PVC extrusion, is enhancing product quality and production efficiency. This technological advancement ensures that suppliers can consistently deliver high-grade pvc coated wire mesh products that meet stringent international standards, thereby reinforcing market confidence and driving further adoption. The rising awareness regarding the environmental impact of material choices is also influencing manufacturers to adopt more eco-friendly PVC formulations and production processes, aligning with global sustainability initiatives.

Manufacturing Process Flow of PVC Coated Wire Mesh

The production of high-quality PVC coated wire mesh involves a meticulous multi-stage process designed to ensure structural integrity, corrosion resistance, and aesthetic finish. Our manufacturing adheres strictly to international quality management systems such as ISO 9001:2015 to guarantee product excellence.

Key Process Steps:

- Material Selection and Preparation: We begin with high-grade low-carbon steel wire, typically Q195 or Q235, known for its excellent ductility and weldability. The wire coils are uncoiled, straightened, and cut to precise lengths, ensuring uniformity for the subsequent welding stage.

- Welding (Welded Wire Netting): The pre-cut wires are fed into automated welding machines. Using resistance spot welding, longitudinal and transverse wires are precisely joined at their intersections to form a robust grid structure. This pvc welded wire mesh base provides the core strength. Advanced PLC-controlled welding ensures consistent mesh aperture and strong weld points, minimizing defects.

- Surface Treatment (Cleaning and Pre-treatment): Before PVC coating, the welded mesh undergoes rigorous cleaning. This includes degreasing, pickling to remove rust and scale, and phosphating to create a conversion coating. This pre-treatment significantly enhances the adhesion of the PVC layer and improves overall corrosion resistance.

- Primer Application: A specialized primer is often applied to the clean metal surface. This acts as an adhesive layer, further strengthening the bond between the steel and the PVC coating, crucial for the long-term integrity of the product.

- PVC Coating Application: This is a critical stage. The pre-treated wire mesh is conveyed through a fluidised bed where it is immersed in a tank of finely powdered PVC (Polyvinyl Chloride). The mesh is pre-heated to a specific temperature, causing the PVC powder to melt and adhere uniformly to the wire surface. Alternatively, for thicker and more robust coatings, extrusion coating processes are utilized. The PVC coating thickness is precisely controlled to meet product specifications.

- Curing and Cooling: After coating, the mesh passes through a curing oven to ensure the PVC fully fuses and cross-links, achieving maximum durability and adhesion. It is then gradually cooled to solidify the coating without cracking or delamination.

- Quality Control and Testing: Each batch of pvc coated welded wire mesh undergoes stringent quality control. Tests include visual inspection for coating uniformity, adhesion tests (e.g., cross-cut test), thickness measurements, pull-out strength tests for welds, and accelerated weathering tests (e.g., salt spray tests per ASTM B117) to simulate long-term performance and corrosion resistance. Service life for our PVC coated products typically exceeds 15-20 years in standard environments.

- Cutting, Rolling, and Packaging: The finished pvc coated welded wire mesh rolls are cut to specified dimensions, carefully rolled, and securely packaged to prevent damage during transit. Custom packaging solutions are available to meet client logistics requirements.

This comprehensive process ensures that our pvc coated wire mesh for sale meets the highest standards of quality and performance for target industries such as petrochemical, metallurgy, water supply & drainage, agriculture, and general construction, offering significant advantages in corrosion resistance and reduced maintenance.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications is crucial for selecting the appropriate pvc coated wire mesh for sale for any project. Our products are engineered to deliver consistent performance, adhering to recognized standards such as ASTM A740 for metallic-coated steel wire woven fence fabric and general requirements for plastic coatings.

Typical PVC Coated Welded Wire Mesh Specifications:

| Parameter | Description | Standard Values/Range |

|---|---|---|

| Material | Low Carbon Steel Wire (Q195/Q235) | Galvanized before or after welding |

| Wire Diameter (Core) | Pre-coating wire gauge | 0.6mm - 4.0mm (23 SWG - 8 SWG) |

| Finished Wire Diameter | Post-coating wire gauge | 0.9mm - 5.0mm |

| Mesh Opening (Aperture) | Size of square or rectangular openings | 6x6mm to 100x100mm (1/4" to 4") |

| PVC Coating Thickness | Layer thickness on each side | 0.2mm - 0.5mm per side |

| Tensile Strength | Of core wire after galvanization | 350-550 N/mm² (for core wire) |

| Coating Adhesion | Adherence of PVC to wire surface | Excellent, no peeling/cracking (ASTM D3359) |

| Corrosion Resistance | Salt spray test duration | > 1000 hours (ASTM B117) |

| UV Resistance | Resistance to degradation from sunlight | High, > 5 years without significant fading/degradation |

| Temperature Range | Operational temperature limits | -30°C to +70°C |

| Roll Length/Width | Standard roll dimensions | Length: 15m, 30m; Width: 0.5m - 2.0m |

| Colors | Standard PVC colors | Dark Green, Black, White, Grey (RAL system available for custom) |

These parameters underscore the robust engineering behind our pvc coated welded wire mesh products, ensuring they meet the stringent requirements of various industrial and commercial applications.

Application Scenarios and Technical Advantages

The versatility of pvc coated wire mesh makes it an indispensable material across a broad spectrum of industries. Its unique combination of strength, corrosion resistance, and aesthetic flexibility offers significant advantages over conventional untreated or merely galvanized options.

Key Application Areas:

- Agricultural and Horticultural Fencing: Ideal for protecting crops, livestock enclosures, and perimeter security in farms. The PVC coating resists fertilizers, pesticides, and animal waste, extending service life significantly.

- Residential and Commercial Security Fencing: Used extensively for garden fences, property boundaries, and commercial premises. The aesthetic color options allow for seamless integration into landscaping designs.

- Industrial Enclosures and Safety Barriers: In manufacturing plants, warehouses, and construction sites, it provides robust and safe partitions, machine guards, and storage cages. Its non-conductive nature (due to PVC) can also be beneficial in certain electrical environments.

- Petrochemical and Coastal Applications: Due to superior corrosion resistance, it is excellent for facilities exposed to chemicals, saltwater, and harsh weather, where longevity is paramount.

- Aviaries and Animal Cages: The smooth, non-toxic PVC surface is safe for animals, preventing injuries that bare wire might cause, while offering robust containment.

- Public Utilities and Infrastructure: Utilized for securing power substations, water treatment plants, and public parks, where durability and low maintenance are critical for public safety and operational efficiency.

- Gabion Baskets and Erosion Control: While typically heavier gauge, PVC coated variants are used in areas requiring enhanced durability against water and soil erosion, offering structural integrity and environmental compatibility.

Technical Advantages:

- Exceptional Corrosion Resistance: The robust PVC layer acts as a barrier, protecting the underlying galvanized steel from moisture, chemicals, salt spray, and atmospheric pollutants. This significantly extends the product's lifespan, particularly in marine or industrial environments.

- Enhanced Durability and Longevity: With a service life often exceeding 15-20 years, PVC coated mesh offers a superior return on investment compared to alternatives requiring frequent replacement or maintenance.

- UV and Weather Resistance: Specialized UV inhibitors in the PVC formulation prevent degradation, fading, and cracking when exposed to prolonged sunlight, ensuring the product retains its protective and aesthetic qualities.

- Aesthetic Appeal: Available in a range of colors, PVC coated mesh can blend seamlessly with natural surroundings or architectural designs, offering a more visually pleasing solution than bare metal.

- Low Maintenance: The smooth, non-porous surface of PVC resists dirt accumulation and is easy to clean, reducing ongoing maintenance costs.

- Safety and User-Friendliness: The PVC coating covers sharp wire edges, reducing the risk of injury during installation and use, making it safer for both installers and those interacting with the mesh.

- Cost-Effectiveness: While the initial investment might be slightly higher than plain galvanized mesh, the extended lifespan and reduced maintenance costs result in a lower total cost of ownership over time.

Vendor Comparison and Customized Solutions

Choosing the right supplier for pvc coated wire mesh for sale is a critical decision that impacts project timelines, budget, and long-term performance. A comprehensive vendor comparison should evaluate not just price, but also quality assurance, customization capabilities, and after-sales support.

Vendor Comparison Matrix:

| Feature/Service | Our Company (Hardware In Store) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Product Quality Certification | ISO 9001:2015, ASTM B117 (Salt Spray) compliant | Basic internal QC | Partial ISO compliance |

| Customization Options | Extensive (mesh size, wire gauge, PVC color, coating thickness, roll dimensions) | Limited (standard sizes/colors) | Moderate (some custom dimensions) |

| Minimum Order Quantity (MOQ) | Flexible, project-based | High, batch production only | Medium, some flexibility |

| Lead Time for Standard Products | 7-14 business days | 14-21 business days | 10-18 business days |

| Warranty Period | 10-year anti-corrosion warranty | 1-3 years | 5 years |

| After-Sales Support | Dedicated account manager, technical assistance, site visits (if required) | Email support only | Phone support during business hours |

| Years in Service/Expertise | Over 20 years specializing in wire mesh products | Less than 5 years | 10-15 years, general metal products |

Customized Solutions:

Recognizing that off-the-shelf solutions may not always fit unique project requirements, we offer extensive customization for our pvc coated wire mesh. Our engineering team works closely with clients to develop tailored specifications, ensuring optimal performance and integration. This includes:

- Specific Wire Gauges and Mesh Apertures: For applications demanding precise filtration, structural support, or specific security levels.

- Custom PVC Colors: Beyond standard green and black, we can match RAL color codes for branding consistency or environmental blending.

- Varying Coating Thicknesses: To meet enhanced corrosion resistance needs in highly aggressive environments.

- Panel and Roll Dimensions: Precision-cut panels or custom roll lengths and widths to minimize waste and streamline installation.

- Special Material Substrates: While typically low-carbon steel, specialized alloys can be considered for unique performance requirements prior to PVC coating.

Our consultative approach ensures that every custom order of pvc coated wire mesh for sale is meticulously planned and executed, delivering precise solutions that align perfectly with client expectations and operational demands.

Application Case Studies and Customer Feedback

Real-world application demonstrates the proven performance and reliability of our pvc coated wire mesh. Here are a few examples showcasing its utility and the value it brings to diverse projects.

Case Study 1: Coastal Infrastructure Protection

Client: Major Port Authority, Southeast Asia

Challenge: Secure perimeter fencing for a new port expansion, requiring material highly resistant to saltwater corrosion, high humidity, and strong winds. The previous galvanized fencing failed prematurely within 5 years.

Solution: We supplied 5,000 linear meters of heavy-gauge pvc coated welded wire mesh (4.0mm core wire, 5.0mm finished diameter, 50x50mm mesh, dark green). The mesh was pre-fabricated into panels and hot-dip galvanized before the thick PVC coating was applied, ensuring maximum protection.

Outcome: After 7 years of installation, the fencing shows no signs of corrosion or degradation, far exceeding the lifespan of previous solutions. The port authority reported significantly reduced maintenance costs and enhanced security. "The PVC coating has proven exceptional against the harsh marine environment. It's a critical investment that paid off," remarked the Head of Facilities.

Case Study 2: Industrial Machine Guarding

Client: Automotive Manufacturing Plant, Europe

Challenge: Create safe, modular machine guarding for robotic assembly lines that are robust, visible, and can withstand accidental impacts while being easy to install and modify.

Solution: We provided custom-sized panels of fine mesh pvc coated wire mesh (25x25mm mesh, 2.0mm finished wire diameter, yellow PVC) for machine enclosures. The yellow color provided high visibility, and the smooth PVC surface prevented snagging or injury to personnel. The welded structure offered superior rigidity for guarding applications.

Outcome: The modular panels were quick to install and met all safety regulations. The plant manager noted, "The yellow PVC coated mesh dramatically improved safety visibility and was very easy for our maintenance team to work with. The durability is excellent in a high-traffic industrial setting."

Customer Feedback:

“We've been sourcing pvc coated wire mesh rolls from Hardware In Store for our residential fencing projects for years. The consistent quality and vibrant color retention are unmatched. Our customers love the finished look and the long-term durability.” – Project Manager, Elite Fencing Solutions.

“For our agricultural enclosures, resistance to harsh weather and animal wear-and-tear is paramount. The pvc coated wire mesh for sale we acquired exceeded our expectations. It's tough, holds up well, and requires almost no upkeep.” – Farm Operations Director, Green Acres Farms.

Trustworthiness: FAQ, Lead Time, Warranty & Support

At Hardware In Store, we prioritize transparency and customer satisfaction. This section addresses common inquiries and outlines our commitment to service excellence, reinforcing the trustworthiness of our products and operations.

Frequently Asked Questions (FAQ):

- Q: What is the lifespan of your PVC coated wire mesh?

A: Our pvc coated welded wire mesh is designed for a service life exceeding 15-20 years in typical outdoor conditions, thanks to its dual protection of galvanization and a robust PVC layer. - Q: Is the PVC coating environmentally friendly?

A: We use high-grade PVC formulations that are lead-free and comply with international environmental standards. We are actively exploring and integrating greener alternatives in our production processes. - Q: Can I order custom colors or specific mesh sizes?

A: Yes, we offer extensive customization options including various wire gauges, mesh apertures, PVC coating thicknesses, and a wide range of RAL colors to match your specific project requirements. - Q: How do you ensure the quality of the PVC coating?

A: Our coating process involves thorough pre-treatment, precise application, and rigorous post-coating testing, including adhesion tests, thickness measurements, and accelerated weathering (salt spray) tests to ensure superior durability and adherence.

Lead Time and Fulfillment:

For standard pvc coated wire mesh for sale products, our typical lead time ranges from 7 to 14 business days from order confirmation to dispatch. Custom orders may require an extended lead time, usually between 3 to 5 weeks, depending on complexity and material availability. We operate a streamlined logistics network to ensure efficient and timely delivery to global destinations. Expedited shipping options are available upon request for urgent projects.

Warranty Commitments:

We stand behind the quality of our products with a comprehensive 10-year anti-corrosion warranty on all PVC coated wire mesh. This warranty covers manufacturing defects and significant degradation of the PVC coating under normal use conditions. Full warranty details are available upon request and provided with every order.

Customer Support and After-Sales Service:

Our dedicated customer support team is available to assist you from initial inquiry to post-installation support. We offer:

- Technical Consultation: Expert advice on product selection, specifications, and installation best practices.

- Order Tracking: Real-time updates on your order status and shipping progress.

- Issue Resolution: Prompt and efficient handling of any product or delivery concerns.

- Documentation: Provision of test certificates, material safety data sheets (MSDS), and installation guides.

Our commitment extends beyond product delivery, ensuring long-term satisfaction and support for all our clients.

Conclusion

The choice of high-quality PVC coated wire mesh is a strategic investment in durability, security, and aesthetic value for any B2B application. Our comprehensive manufacturing process, adherence to rigorous technical standards, and commitment to customized solutions ensure that every product delivers exceptional performance. From robust industrial enclosures to elegant residential fencing, the advantages of corrosion resistance, longevity, and low maintenance make PVC coated wire mesh an unparalleled solution. Partner with us to leverage our expertise and elevate your projects with superior pvc coated wire mesh for sale products.

References:

- ISO 9001:2015. Quality management systems – Requirements. International Organization for Standardization.

- ASTM B117. Standard Practice for Operating Salt Spray (Fog) Apparatus. ASTM International.

- ASTM A740. Standard Specification for Metallic-Coated Steel Wire Woven Fence Fabric. ASTM International.

- Plastics Engineering Handbook of the Society of Plastics Engineers. (2014). Hanser Publications.

- Corrosion Engineering: Principles and Practice. (2012). Pierre R. Roberge. McGraw-Hill Professional.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories