Oct . 26, 2025 14:30 Back to list

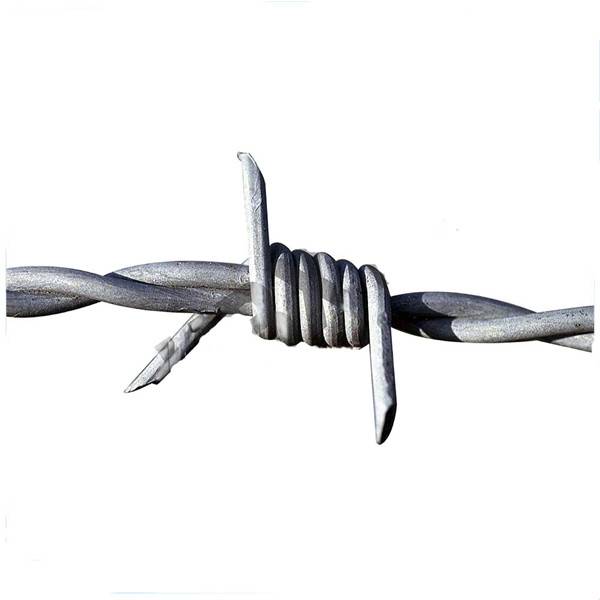

Barbed Wire Wholesale: Durable, Rust-Resistant, Easy Install

Galvanized Perimeter Wire: field notes from a fence-obsessed editor

If you work around farms, utilities, or just big open land, you learn fast what lasts and what doesn’t. Barbed Wire that’s properly galvanized tends to outlive its critics—and, to be honest, a few budget posts along the way. I’ve walked fence lines from Inner Mongolia to West Texas; the patterns repeat. Good steel, decent zinc, correct twist, and smart spacing save you money and headaches.

What’s different here

This model—formally “Barbed Wire With Galvanized Surface”—comes out of No.29, Taihua Street, Shijiazhuang, China. The factory has leaned into practical specs and fast-turn service. Many customers say the “it just works” factor is high. Actually, the headline features are simple: customizable barb length, flexible wire gauge, and predictable zinc coating that doesn’t flake under a basic bend test.

Product specs (real-world, not brochure talk)

| Parameter | Typical/Custom Range (≈, real-world use may vary) |

| Core wire diameter | 1.6–3.2 mm (popular: 2.0/2.5 mm) |

| Barb length | 1.5–3.0 cm |

| Barb spacing | 75–150 mm |

| Zinc coating mass | ≈ 70–230 g/m² (Class depends on standard) |

| Tensile strength | ≈ 380–550 MPa (mild steel) or higher on request |

| Finish | Electro- or hot-dip galvanized |

Process flow (quick but nerdy)

- Materials: low-carbon steel wire (e.g., Q195/SAE1006), verified chemistry.

- Drawing and annealing: to target diameter and ductility.

- Galvanizing: hot-dip or electro; coating mass controlled per ASTM A641 or EN 10244-2.

- Forming: double-strand twist; barbs wrapped 2–4 turns; spacing jig-controlled.

- Testing: coating mass (ASTM A90/ISO 1460), salt spray (ISO 9227), tensile (ASTM A370), bend/adhesion checks.

- Packing: coils with moisture barrier; label traceability.

Service life? Inland, Barbed Wire with heavier zinc runs ≈ 10–20 years; coastal or industrial air can cut that in half unless you step up to higher coating classes. I guess that’s not surprising if you’ve ever smelled sea salt on a Monday and rust on a Friday.

Where it’s used

Agricultural fencing, ranch perimeters, utility ROWs, rail/road corridors, solar farms, temporary crowd control (with caveats), and wildlife deterrence when paired with smooth wires. Barbed Wire is still the quickest “line in the sand” for large distances.

Vendor snapshot (why buyers compare)

| Vendor | Coating type | Coating mass | MOQ | Lead time | Certs | Warranty | Price (≈/100 m) |

| HardwareInStore | Hot-dip / Electro | 70–230 g/m² | 1 pallet | 7–12 days | ISO 9001, SGS test | 12–24 months | US$ 18–32 |

| Vendor A | Hot-dip | 100–200 g/m² | 2 pallets | 15–20 days | ISO 9001 | 12 months | US$ 20–35 |

| Vendor B | Electro | 50–120 g/m² | 1 pallet | 10–15 days | — | — | US$ 15–25 |

Notes: indicative figures; freight, coating class, and steel prices swing the totals.

Case notes from the field

Barbed Wire on a 1,200-acre Texas ranch: upgraded to heavier zinc (≈200 g/m²) and widened post spacing by 10%. Feedback after 18 months: fewer re-tensions, no white rust despite spring storms.

Utility solar site, MENA: specified 2.5 mm core, 4-point barbs, 100 mm spacing. Salt-spray tested to 240 h (ISO 9227) pre-shipment. Security team reported “clean deterrence, minimal maintenance” in year one.

Why buyers pick it

- Customization: barb length 1.5–3 cm and wire 1.6–3.2 mm on tap.

- Fast delivery: 7–12 days is common, even quicker off-peak.

- 24-hour support: yes, a real person follows up (seems small, matters big).

Standards, tests, and paperwork

Typical compliance: ASTM A641/A641M for zinc-coated wire; EN 10223-1 for fencing wire; EN 10244-2 for zinc coating classes. Coating mass verified per ASTM A90/ISO 1460; corrosion screened with ISO 9227. Many batches ship with ISO 9001 QA, and third-party SGS test reports on request. All that translates to Barbed Wire that doesn’t surprise you in year two.

Quick ordering tip

Send location (coastal/inland), target lifespan, and whether livestock leans on the line. You’ll get the right coating mass and spacing. It sounds fussy, but it prevents 90% of issues with Barbed Wire.

Origin: No.29, Taihua Street, Shijiazhuang, China

Authoritative citations

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories