Oct . 24, 2025 16:40 Back to list

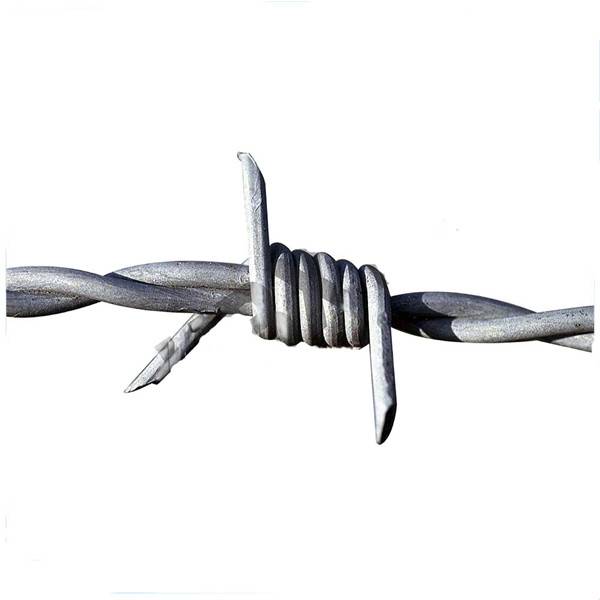

Barbed Wire Security Fencing—Durable, Anti-Rust, Low Cost

Galvanized Perimeter Fencing That Works In The Real World

When ranchers, contractors, or even rail operators talk about rugged perimeter control, they almost always end up here: Barbed Wire. I’ve toured mills from Hebei to Houston, and—honestly—the winning products tend to nail three things: consistent zinc coating, a clean barb, and sane lead times. This galvanized line from Shijiazhuang checks those boxes, and then some.

What’s trending (and what isn’t)

Security buyers have shifted from cheap, thin-coat imports to heavier zinc, because field failures are expensive. Surprisingly, many customers say they’ll pay a little more for stable tensile strength and barb uniformity. Also trending: quick customization—different barb spacings for livestock vs. construction sites. It sounds small; it isn’t.

Core product snapshot

Product: Barbed Wire With Galvanized Surface (Origin: No.29, Taihua Street, Shijiazhuang, China). Short description—Barb length: 1.5–3 cm; Wire diameter: 1.6–3.2 mm. Notes: Customization, fast delivery, 24-hour service. In fact, that last bit matters during emergencies (storm damage, festival perimeters, you name it).

| Parameter | Typical Range | Notes (real-world may vary) |

|---|---|---|

| Barbed Wire diameter | ≈ 1.6–3.2 mm | Low-carbon steel core (Q195/Q235) |

| Barb length | ≈ 1.5–3 cm | Single or 4-point options |

| Barb spacing | ≈ 75–100 mm | Adjustable for cattle vs. security |

| Tensile strength | ≈ 380–550 MPa | Balanced for strength + workability |

| Zinc coating (mass) | ≈ 80–230 g/m² | ASTM A121 / EN 10223-1 classes |

| Service life | ≈ 10–20 years | Shorter in coastal/salt-laden air |

How it’s made (quick process flow)

Wire rod selection → drawing → annealing → galvanizing (hot-dip or electro, depending on spec) → double-strand twisting → barbing (accurate pitch control) → tensioning → QA. Testing includes coating mass per ASTM A90/A90M, barb spacing and tensile tests per ASTM A121/EN 10223-1, and optional salt-spray per ASTM B117 for benchmarking. To be honest, the wrap/adhesion checks are underrated; they predict real field behavior.

Application snapshots

- Agriculture: cattle fencing and range boundaries

- Construction: temporary sites, storage yards

- Rail and energy: corridor demarcation, remote substations

- Disaster response: rapid perimeter setups (fast delivery matters)

| Vendor | Standards | Coating mass | Lead time | Customization | Notes |

|---|---|---|---|---|---|

| HardwareInStore (Shijiazhuang) | ASTM A121, EN 10223-1, ISO 9001 | ≈ 80–230 g/m² | ≈ 7–15 days | Barb spacing/length, coil size | 24-hour service; fast dispatch |

| Regional Mill (Domestic) | ASTM A121 | ≈ 90–200 g/m² | ≈ 14–25 days | Limited options | Stable, mid-volume |

| Trading House (Overseas) | EN 10223-1 | ≈ 70–150 g/m² | ≈ 20–35 days | On request | Price-driven; verify specs |

Field performance and feedback

Real projects report fewer red rust spots after two winters (central US), which aligns with higher coating mass. Installers say the coils unspool cleanly—small thing, but it speeds jobs. One buyer mentioned the barbs were “mean but tidy”—exactly what you want in Barbed Wire.

Mini case studies

• Cattle Ranch, NSW: Upgraded to heavier zinc class; repair calls dropped ≈ 30% year-on-year.

• Wind Farm, Inner Mongolia: Customized barb spacing at 75 mm for tighter deterrence; 10-day delivery kept the schedule intact. That fast turnaround… it saved them.

Specs, compliance, and service

- Standards: ASTM A121 (barbed), EN 10223-1; coating mass verified via ASTM A90/A90M.

- Optional salt-spray benchmarks: ASTM B117 (lab correlation only; field life varies).

- Quality: ISO 9001:2015 QMS; mill test certificates available on request.

- Customization: barb length/spacing, coil weight, hot-dip vs. electro-galv preferences.

- Service: 24-hour response, fast delivery from Shijiazhuang hub.

If you need practical, durable Barbed Wire without the drama, this galvanized line is a sensible pick. Pricing is fair; the zinc is honest; support is awake. I guess that’s all most sites need.

Authoritative citations

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories