Feb . 11, 2025 05:48 Back to list

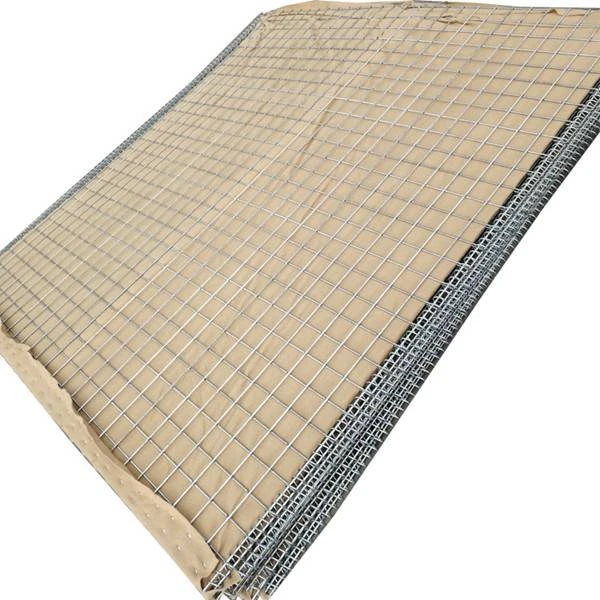

1/2 inch galvanized chicken wire

When selecting a 1/2 inch wire mesh screen, it is essential to consider the specific requirements of your project. Factors such as the material, wire diameter, and the environment in which the mesh will be used play a pivotal role in determining the most suitable product. Consulting with industry experts or conducting thorough research can provide valuable insights and guidance. Moreover, opting for manufacturers with a reputation for quality and reliability can further enhance the trustworthiness of your choice, ensuring that you invest in a product that meets high standards. User experiences with 1/2 inch wire mesh screens reveal a high level of satisfaction, often citing the screen's ease of installation and adaptability as significant benefits. Many users appreciate how the mesh can be custom-cut to fit specific dimensions, reducing waste and cost. Additionally, its lightweight nature facilitates easier handling and transport, making it a preferred choice for both DIY enthusiasts and professional contractors. In conclusion, the 1/2 inch wire mesh screen emerges as a product that meets the rigorous demands of various applications with remarkable efficiency and durability. Its carefully engineered design caters to a multitude of needs, offering a practical solution for challenges faced in construction, agriculture, and beyond. By selecting a 1/2 inch wire mesh screen that aligns best with your specific requirements and sourcing it from reputable suppliers, you leverage a product characterized by its experience, expertise, authoritativeness, and trustworthiness. This decision not only ensures optimum performance but positions you to capitalize on its long-term benefits effectively.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories